Steve - Thanks for that suggestion but my 4 jaw is way too big and too heavy to mount on the rotary table. I do have a four inch 4 jaw that fits it but it will not hold the flywheel. My lathe 4 jaw has the spindle threads as part of the casting so it would take some finagling to get it secured. I took Pete's suggestion and made a larger plate. In the past I have wished I had "just another inch" on my rotary table and this will give it to me.

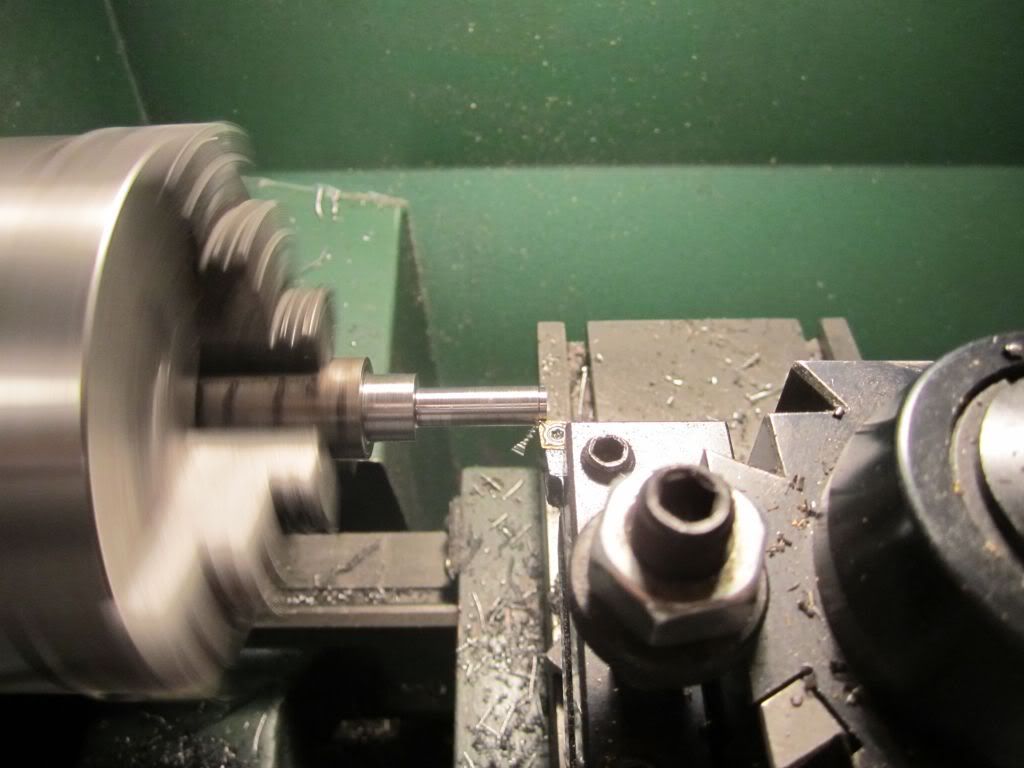

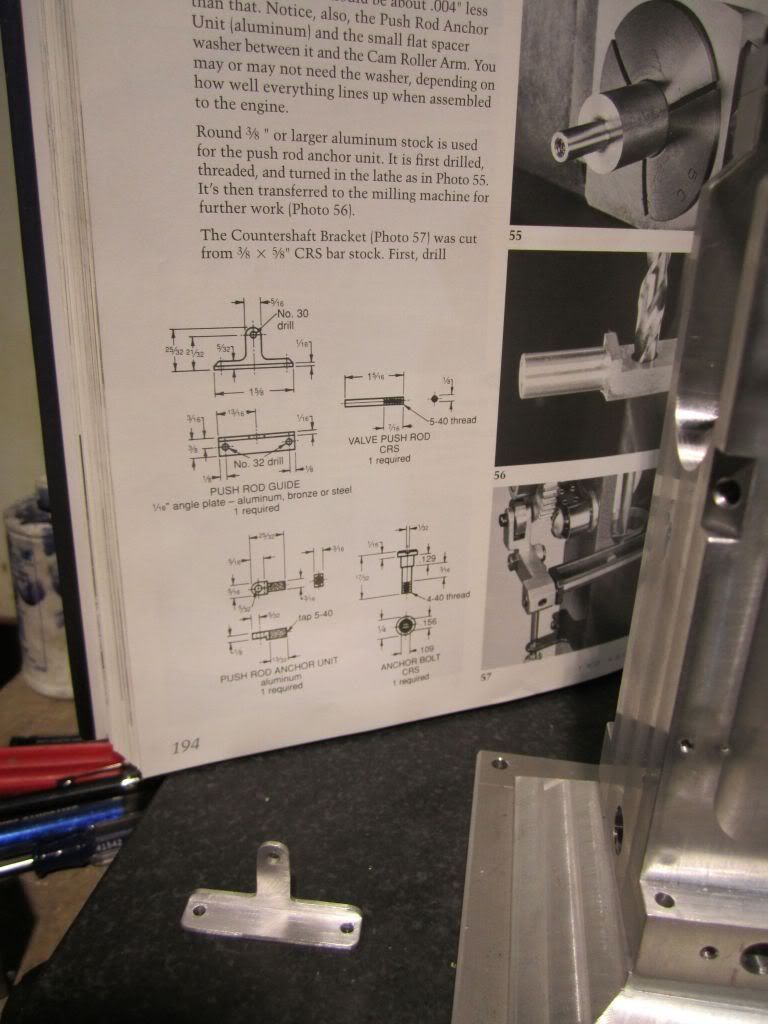

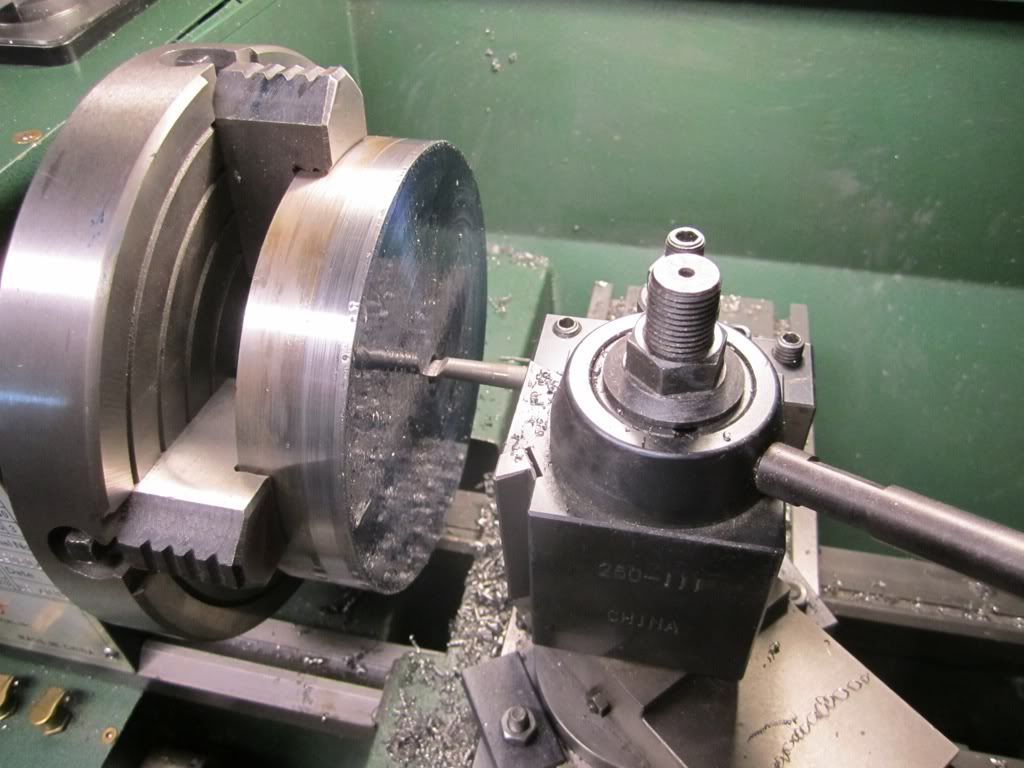

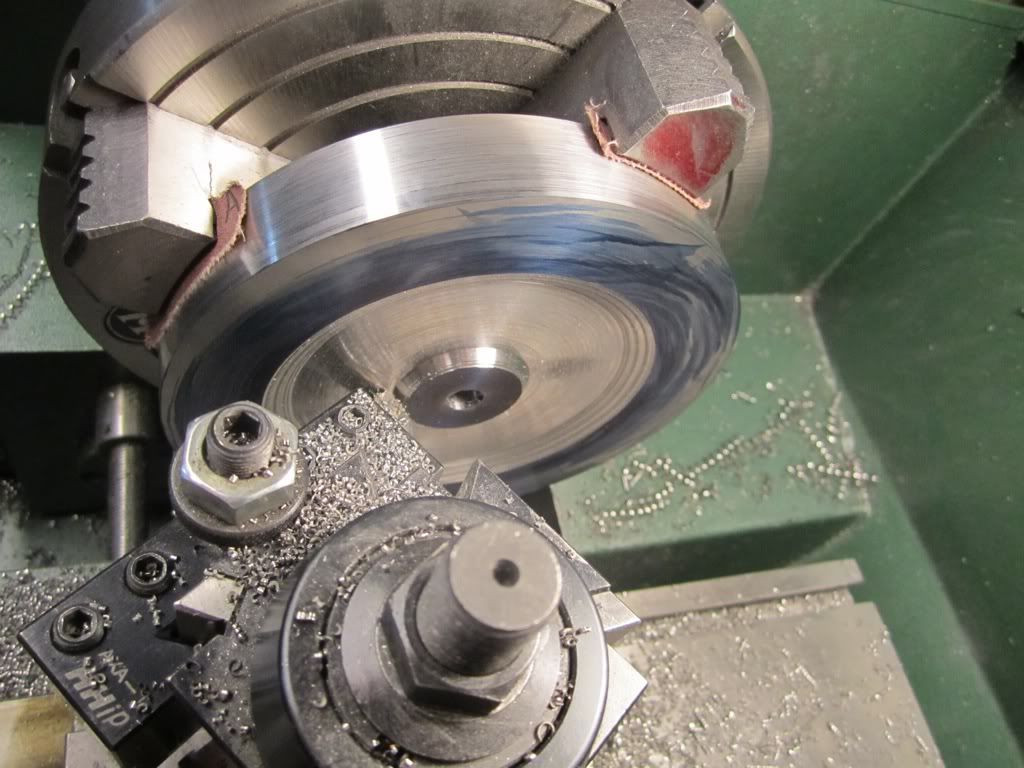

I didn't show a step by step of the plate construction but I sawed it out of a piece of aluminum tooling plate, and finished it on the lathe.

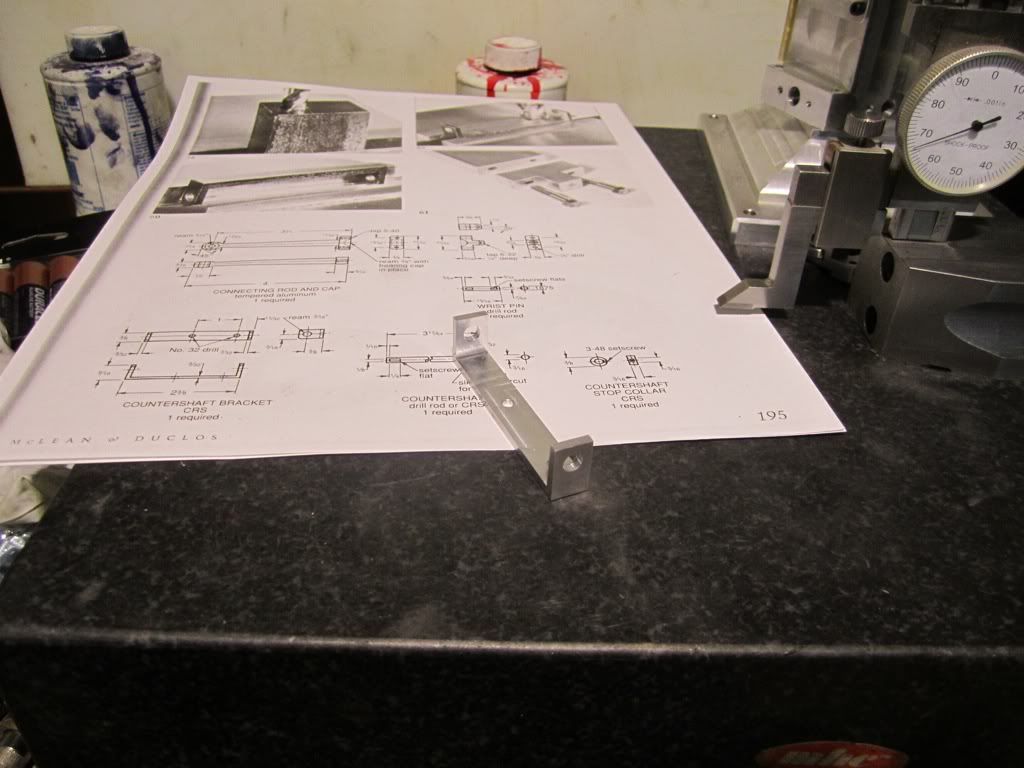

The two sets of holes are for mounting it on the lathe to turn the edges (outside holes) and the other holes are for mounting it on the rotary table.

Since the flywheel is cut away on the diameter of the mounting holes I did not need to countersink the mounting bolts.

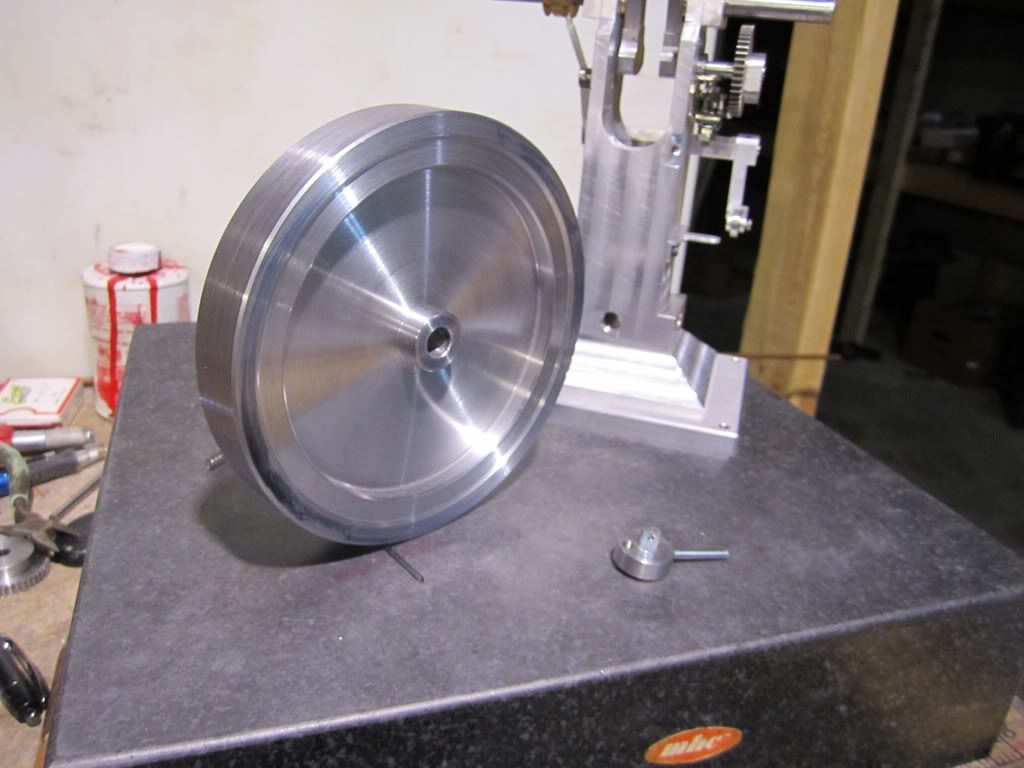

In retrospect I wish I had made it about a half inch larger and I could have drilled and tapped so clamp holes on the periphery but I was also concerned about making it too large and not being able to read the vernier dial on the crank.

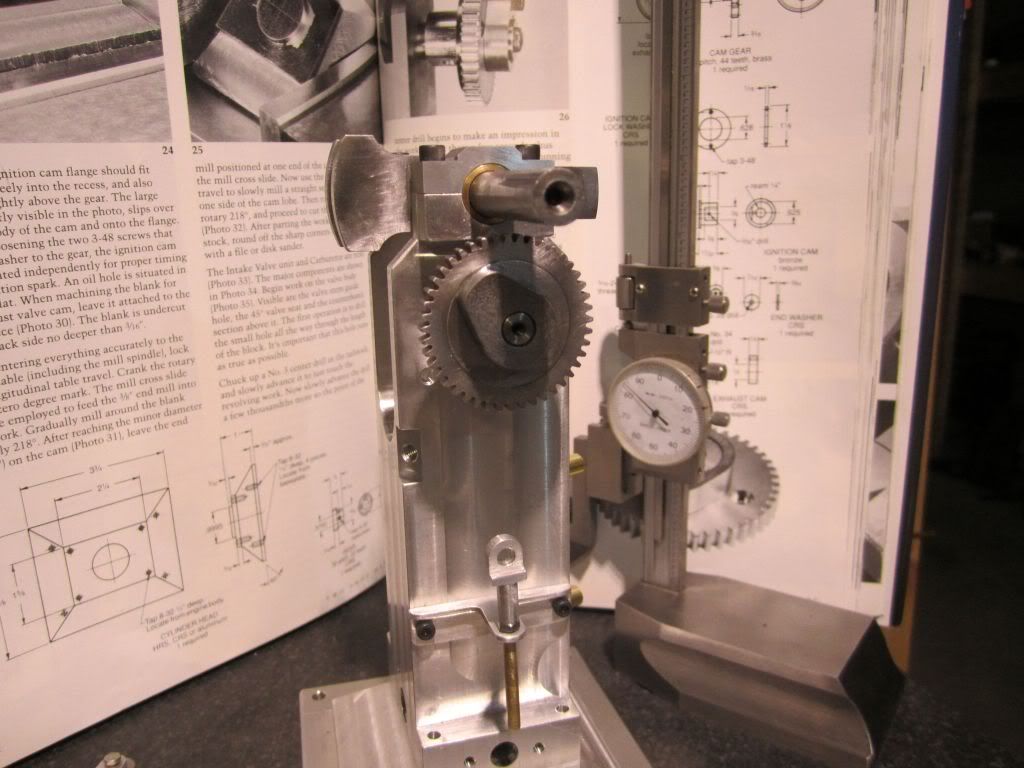

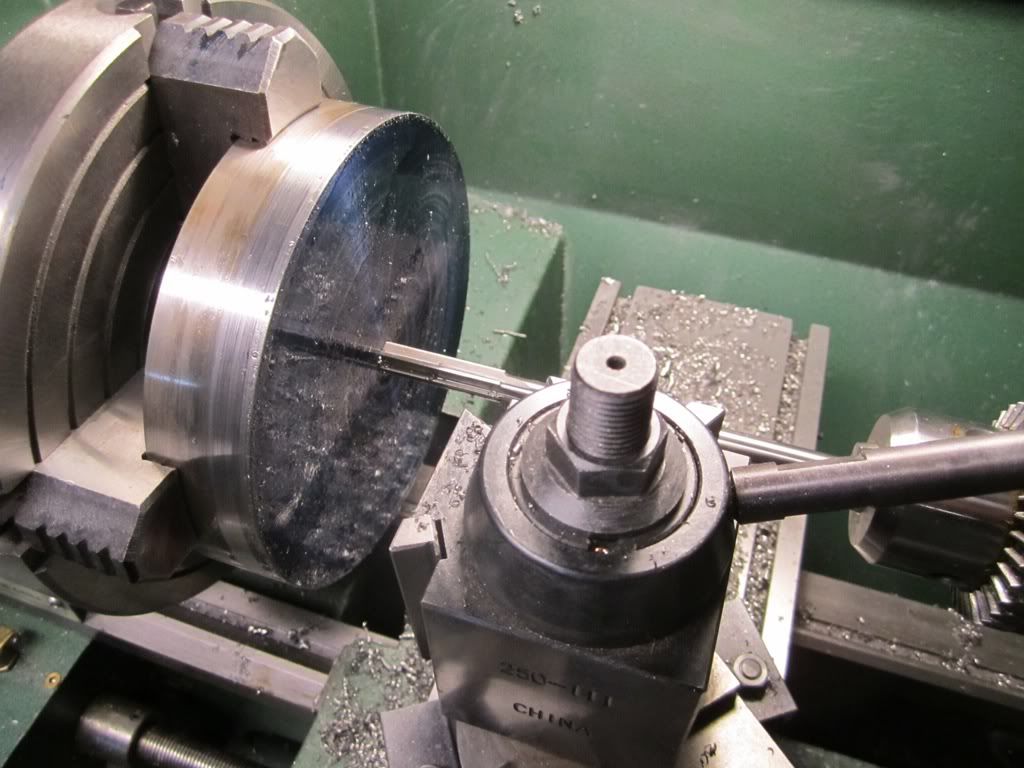

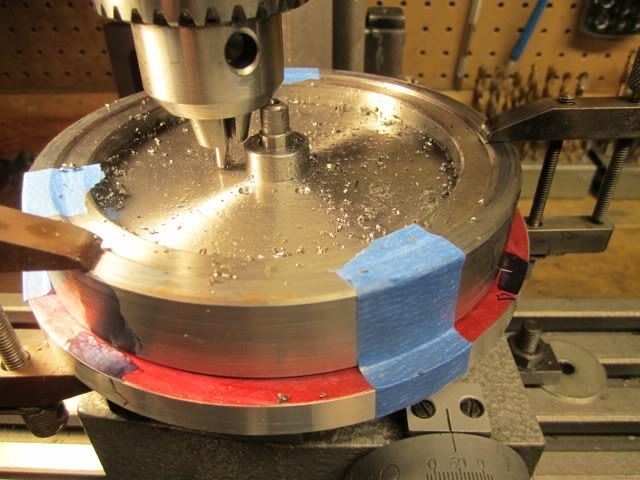

I made three "witness" marks around the edge and used machinists clamps to hold the flywheel to the table. This was a pain because I had to move them one at a time as they rotated to clear the dial. After this it was a matter of locating the spindle and starting to make holes. I also put some tape in three places to serve as additional witness marks since it would show if the flywheel moved. I was not too concerned since there was no rotational force on anything at this point.

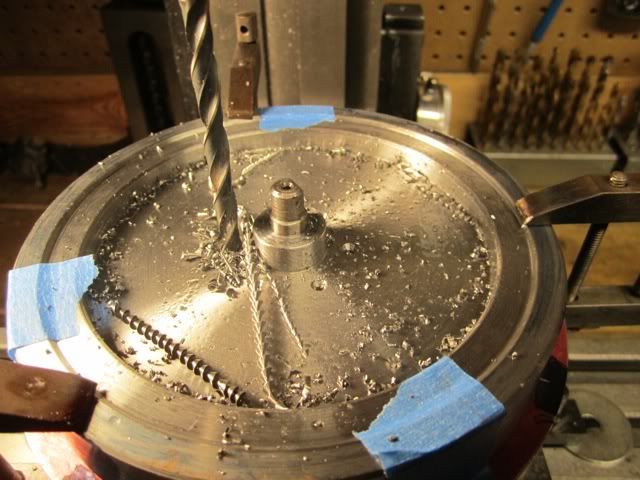

For each hole I indexed 60 degrees, center drilled and repeated. I then put a 15/64 drill in and indexed and drilled and finally a .250 reamer and indexed and reamed each hole.

This ended up being a a pain with having to move the clamps around and on the outer holes I would index, center drill, then drill, then ream. It made for a lot of changing drill but it only required moving the clamps around a minimal amount.

I was quite happy with the results...

A valid question would be "why the need to drill and ream the holes since they will be milled away?" The reason is, I wanted to use two dowel pins to align the flywheel on the mill table and wanted to have a close tolerance hole for the pins. Maybe a little overkill but at this point I do not want to mess it up.

The next step is to mill out the webs....