Admiral_dk said:

I'm not sure that I hear a ping from detonation - my first instinct suggest that valve / hit & miss mechanism, though I might be completely of the charts with that.

Try to disable the hit & miss mechanism first and see if it runs the way one would expect (and be ready to kill the ignition if the rpm rise too much)

I am going to look into that as I, like you thought it might be a mechanical sound but the engine has so much compression that it is difficult to turn over on a compression stroke. I took the flywheel off and with my two thumbs on the crank webs i almost could not get the piston down. With the spark plug removed or the exhaust valve open the engine turns very freely. If you look at the run video it is coasting many cycles between hits. I am looking into both increasing the octane and looking into Rudy's suggestion as well as looking at ways to decrease the compression ratio. Thanks for your input as it is certainly worth looking into.

As I mentioned yesterday, I want to complete the two last parts before I tear it down for painting and final twiddling.

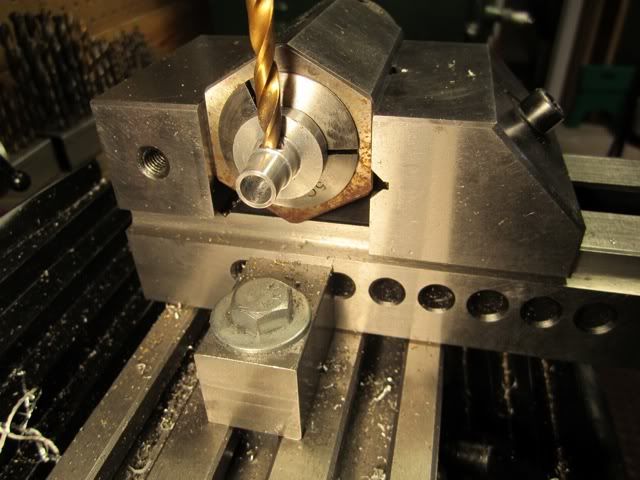

On my previous post, I completed the two outer muffler parts. Today I turned the muffler baffle. After turning the back side to dimensions I put the part in a collet on the mill and cross drilled the four holes.

After completing the holes I put it back on the lathe in a 7/16 collet to finish the front side. was a bit of turning work, a bit of filing, and a bit on 400 and 600 Wet or Dry.

The three parts were complete so the arbor press was next to press the baffle into the front body.

At his point the three parts were now two parts.

The next operation was on the rotary table to locate, drill and in the case of the rear shell, tap the 2-56 holes.

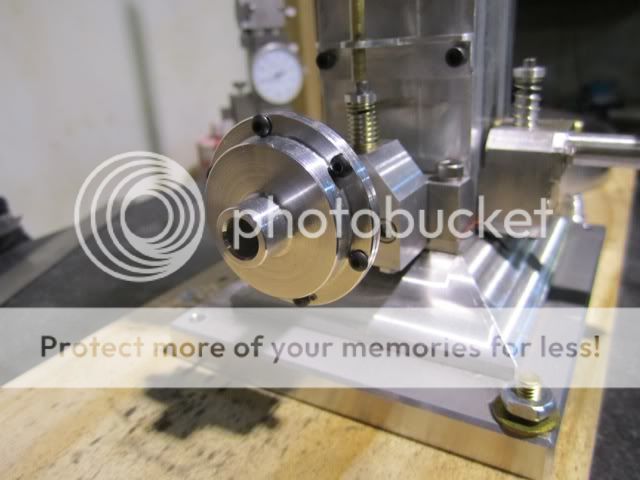

At this point the muffler was complete.

And here it is in its new home...

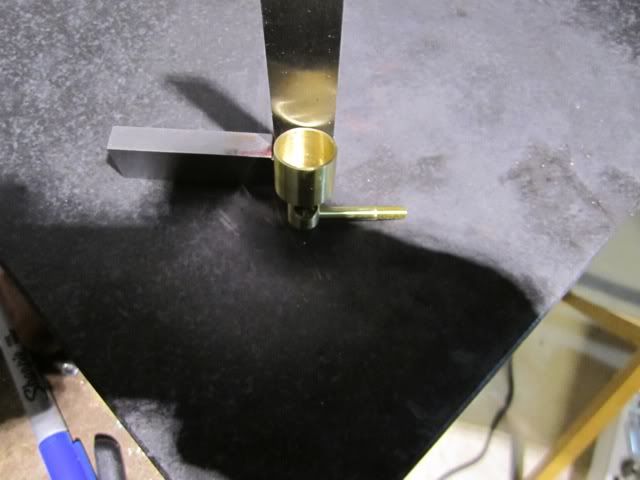

The next part is the oiler which is made up of 5 different parts. Four of which are fitted and soft soldered together. The stem, the sight tube the reservoir, and the cap.

Here are the first two completed parts...

And here is the reservoir..

Here are the first three parts just fitted together...

Perhaps tomorrow I'll be able to complete this and get it mounted... I'll keep you posted...