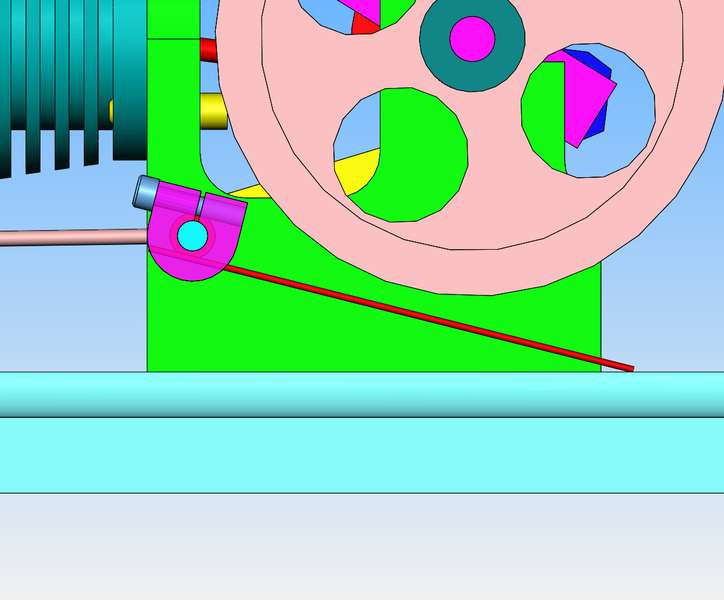

This morning I made a top for the alcohol burner but haven't soldered it on yet. I ordered a set of six 1/8" diameter wicks from Amazon, and I don't want to make the spout that holds the wick until I have the wicks in hand. I've also been looking at what happens with the engine timed the way I have it. When the cylinder is sticking out to the left, I want the flywheels to rotate clockwise. (This keeps from having to run my hand thru the flame after I've flicked the flywheel.) So--piston is at top dead center and valve is wide open. I start rotating the flywheel clockwise. Thru the first 45 degrees of rotation the valve stays open, sucking in flame. During the second 45 degrees of rotation the valve begins to close but hasn't fully closed yet. Thru the third 45 degrees of rotation the valve closes completely. During the last 45 degrees of rotation the valve remains closed and the piston reaches bottom dead center. In the next 45 degrees of rotation as the piston begins to be sucked back up towards top dead center, the valve stays closed for about the first 22.5 degrees, then begins to spring open and by the time it reaches 45 degrees the valve is fully open. The valve then remains open right on thru the top dead center piston position and doesn't close again until the whole cycle repeats itself.