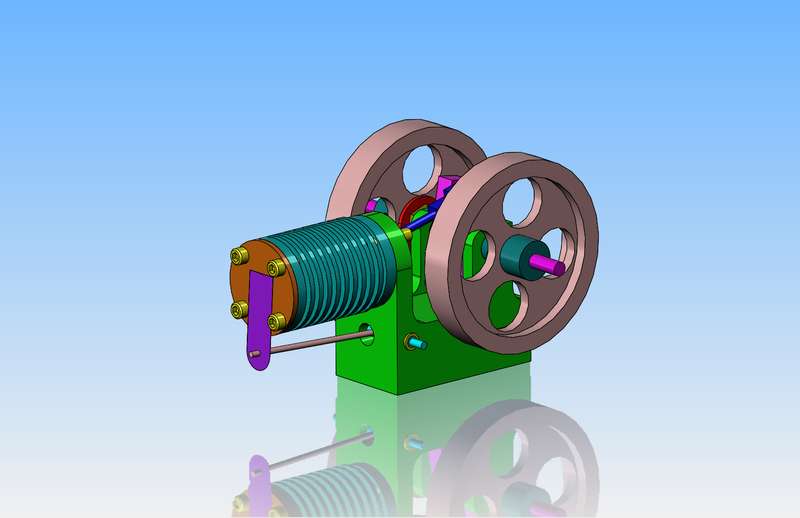

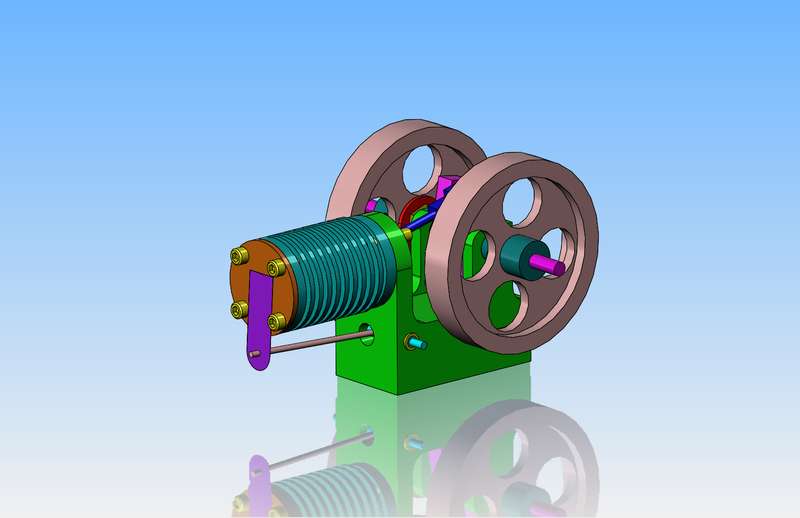

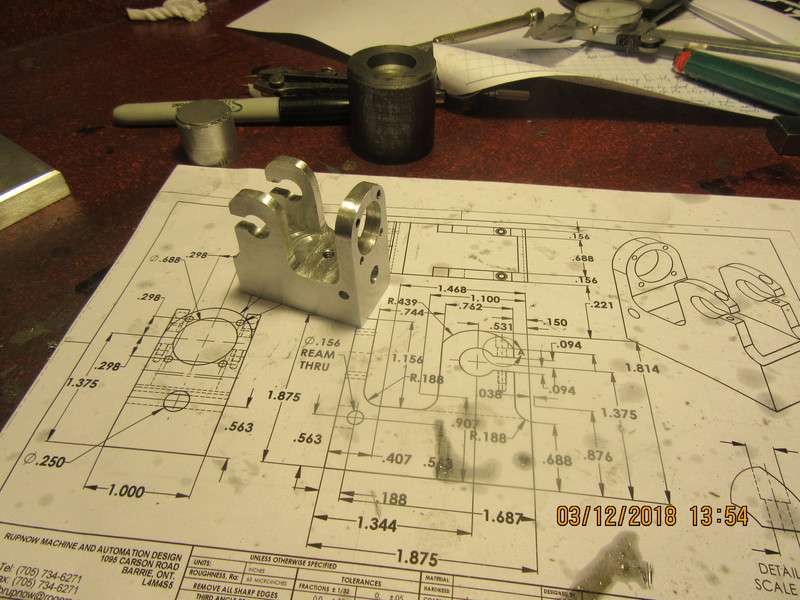

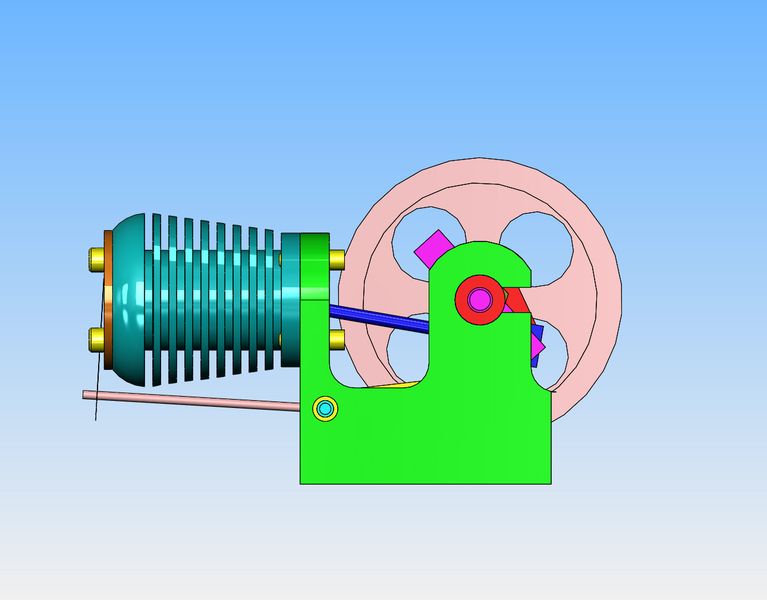

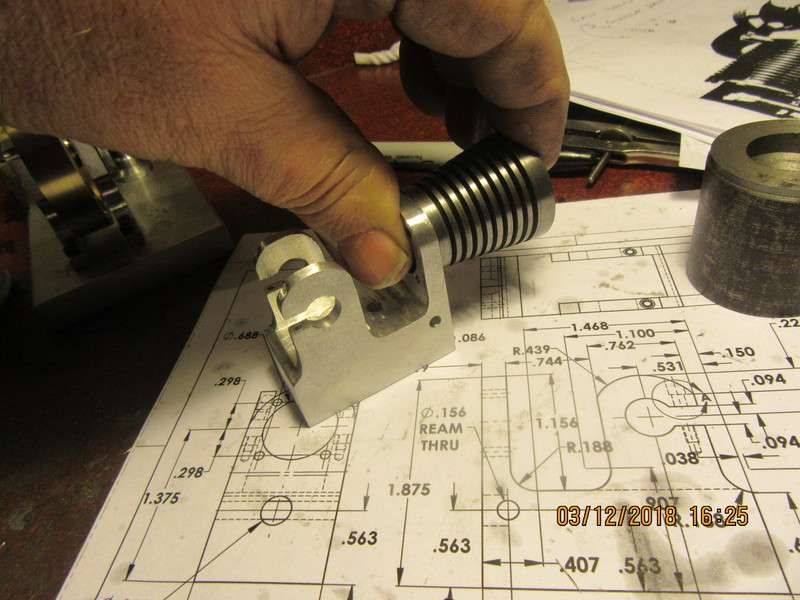

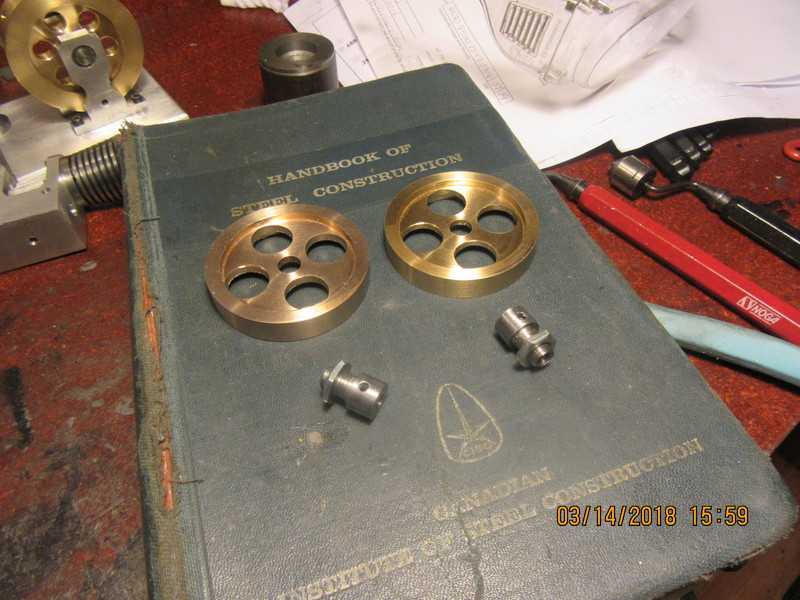

I just finished building the latest flame-licker engine designed by Jan Ridder, and my results were not what I hoped for. I did get it to run--long enough to get a video of it running.--But barely. I found it to be an easy build but a very temperamental and difficult engine to run. I don't think this was a result of my workmanship, as I have 25 other self built engines which all run quite well. It may have been my choice of 316 stainless steel for the cylinder. I tried it with a cast iron piston and valve and with a machinable graphite piston and valve, but the performance was no better with either material. I still want a flame licker engine which starts and runs repeatably, and after doing a fair bit of research have decided to build a "Poppin" engine from plans by Dr. J.R. Senft. I will attempt to post my progress and pictures of this engine as it is built.