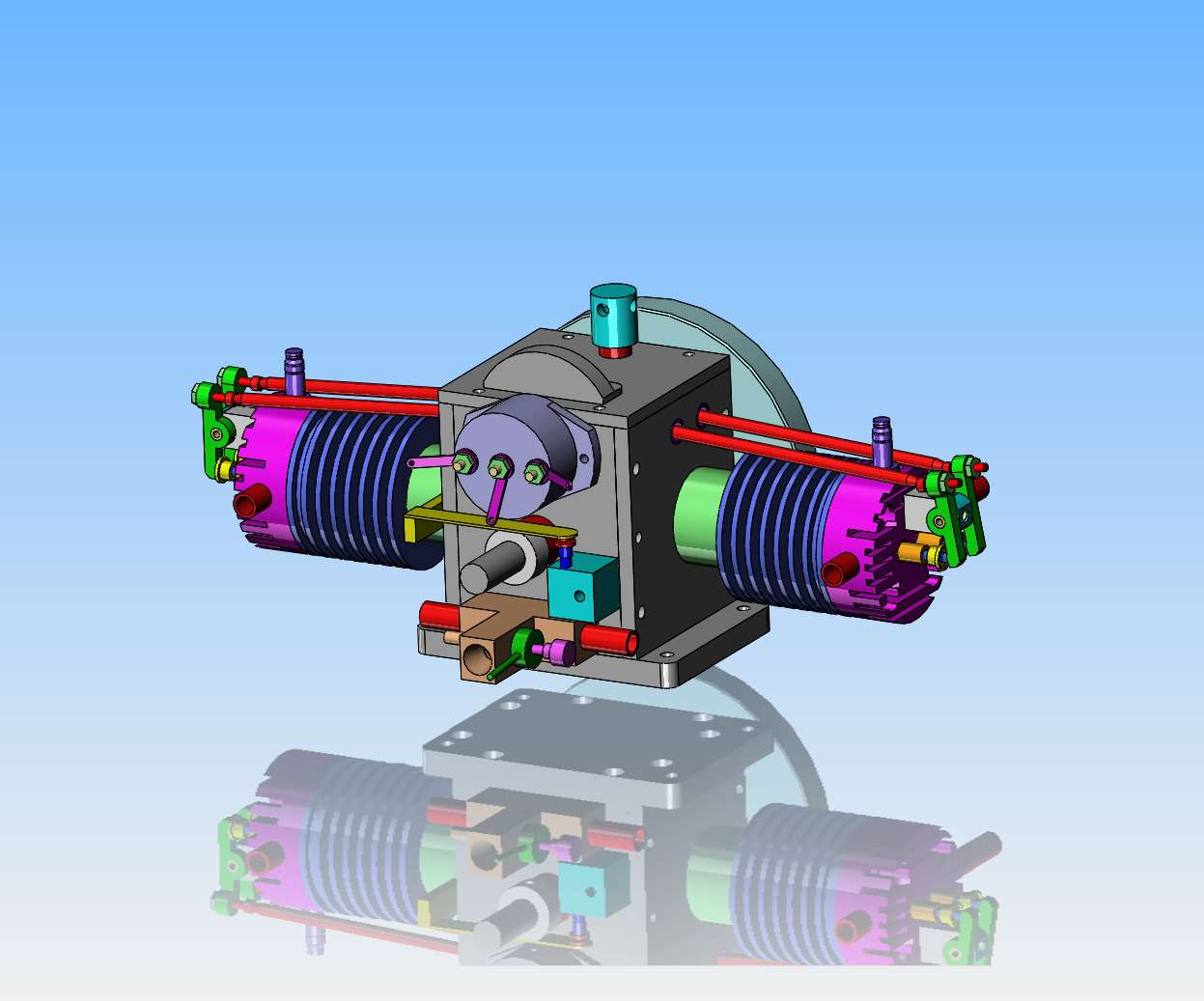

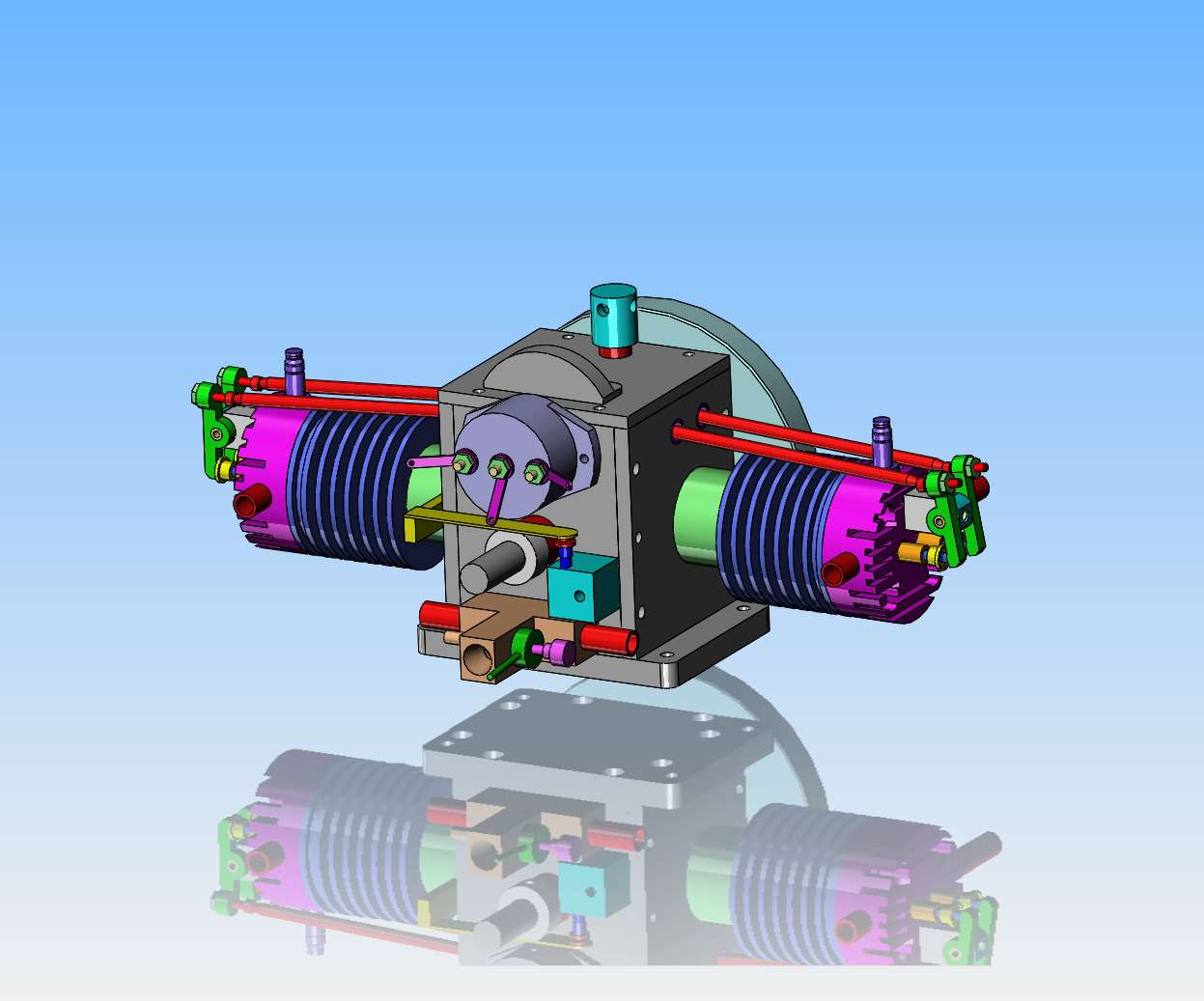

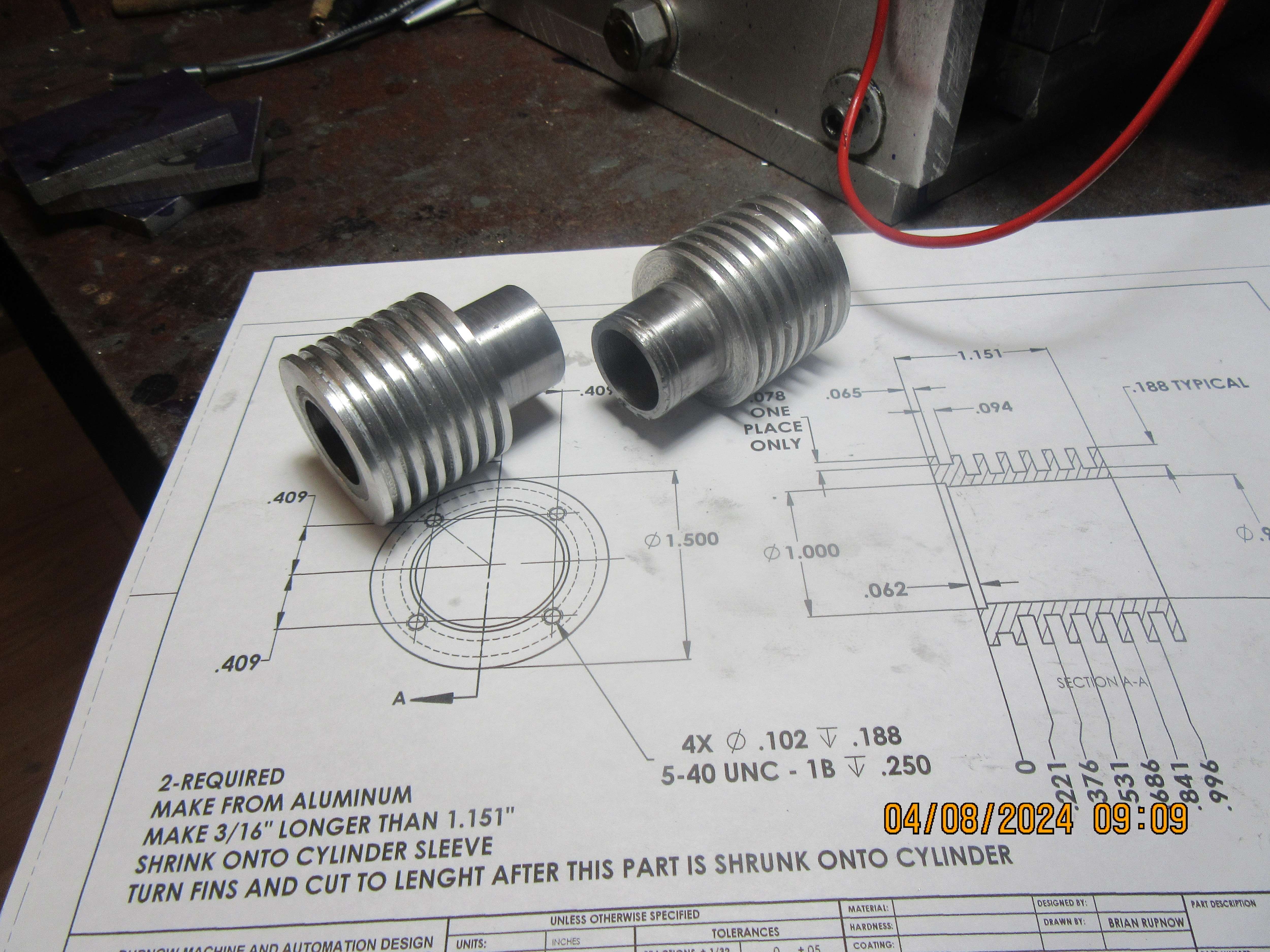

As work on my inline twin engine comes to an end, (and no, it isn't running yet) I've been feeling the urge to design something. Last week I purchased the plans to "Upshur's opposed twin engine". The drawing package is really well done, and is in 2D format. One of the big pluses about this engine is that it runs a distributor cap and rotor, something I have wanted to know more about. I have redone the plans in 3D format to familiarize myself with all of the components, and it really is a sweet looking engine. I won't be selling the plans to this engine, but it should make for a very interesting build. Andrew Whale of the U.K. just happens to be building this same engine currently. I will follow the plans for this engine---to a point. I may use a purchased set of ignition points instead of the spring brass with tungsten points soldered to it, which is used in the original plans. Stay tuned, as after I get my inline twin engine running, this will be my next build.----Brian