doc1955

Gone

- Joined

- Aug 26, 2009

- Messages

- 1,261

- Reaction score

- 163

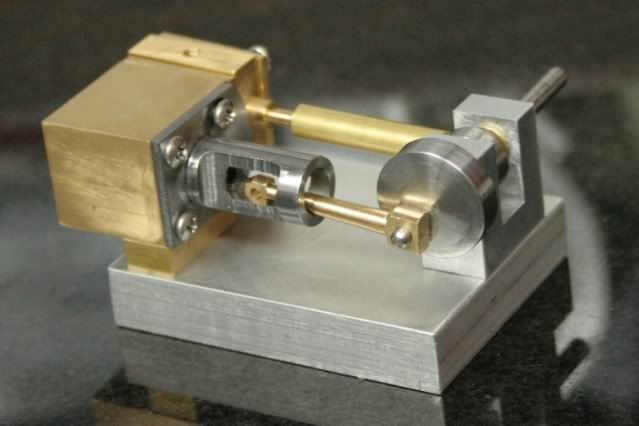

Looking good I can relate to small. That steam chest looks great you've done some excellent looking work!

I also can relate to not getting much shop time. Between my real job and all the other things going on you try and get as much done as you can when you do get to the shop.

I like the m&m in the pics trouble here there would be no m&m's left by the time I got to taken a picture if you know what I mean. :big:

Keep up the nice work and pics!

I also can relate to not getting much shop time. Between my real job and all the other things going on you try and get as much done as you can when you do get to the shop.

I like the m&m in the pics trouble here there would be no m&m's left by the time I got to taken a picture if you know what I mean. :big:

Keep up the nice work and pics!