You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Elmer's #6 -- Slider, a slide valve engine

- Thread starter ksouers

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

The past couple weeks have been hectic, as usual. I only had a couple pieces left to do, so I grabbed time as I had it available to finish them off.

Well, yesterday I got a bad case of get-it-done-itis. All I had left was the flywheel so I slapped it out, drilled a quick hole, tapped it and turned down a brass pin to tighten up against the crankshaft. Did some fiddling and tweaking and now it runs!

And just to prove it can be done, here is a video of it running on an aquarium air pump. The video makes it look like it's running faster than it is. I guess it's running about 150 RPM on about a 1/2 - 1 pound of air pressure. Sorry about the crappy video, it's an old Kodak and video was not a high priority at the time.

I still have some details to finish, like a proper grub screw and a bit of filing and polishing. Plenty of time for that. The main thing is that it runs.

It's been fun. Thanks everyone for the support.

Well, yesterday I got a bad case of get-it-done-itis. All I had left was the flywheel so I slapped it out, drilled a quick hole, tapped it and turned down a brass pin to tighten up against the crankshaft. Did some fiddling and tweaking and now it runs!

And just to prove it can be done, here is a video of it running on an aquarium air pump. The video makes it look like it's running faster than it is. I guess it's running about 150 RPM on about a 1/2 - 1 pound of air pressure. Sorry about the crappy video, it's an old Kodak and video was not a high priority at the time.

I still have some details to finish, like a proper grub screw and a bit of filing and polishing. Plenty of time for that. The main thing is that it runs.

It's been fun. Thanks everyone for the support.

It runs very well, Kevin. Nice and smooth. Good sound, too.

I figure when my engines run on an aquarium pump, I've done alright.

I wondered what the heck that was flailing around the crank, 'til I saw your bit about "proper grub screw".

You did a nice job here. I'd like to see some more pics...

Thanks for the vid!

Dean

I figure when my engines run on an aquarium pump, I've done alright.

I wondered what the heck that was flailing around the crank, 'til I saw your bit about "proper grub screw".

You did a nice job here. I'd like to see some more pics...

Thanks for the vid!

Dean

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

Congratulations Kevin.

Running on such low pressure is certainly a mark of quality I'd like to achieve some day. I'm making progress though...I'm down to about 90. ;D

Running on such low pressure is certainly a mark of quality I'd like to achieve some day. I'm making progress though...I'm down to about 90. ;D

Thanks Dean. I'll try to get some beauty shots a bit later. I was wondering what you were talking about with "Good sound, too". It hardly makes any noise at all. I had to watch it again with the sound turned up and then I heard the clacking sound. Odd, because there is almost no sound at all, certainly not a rattle or clacking. It's so quiet you can hear the hum from the pump. The shop was completely quiet so that sound must be the chuff from the exhaust.

Thanks Zee.

You do really good work, so stop being so down on yourself. I'll bet you can do it with your engines right now.

The key is to reduce friction. For me, that means a proper break-in period. On this engine when I had finished the cylinder, crank, rods and guide I started running everything using the lathe to turn the crank. The engine probably had 5 hours of running before air even touched it. Oh, and I use lots of crappy oil. I use 3-in-1 for break-in purposes. It does lubricate, but mostly it's to flush out the ultra-fine chips from the break-in. There were also a couple complete tear-downs and thorough cleaning in alcohol.

When assembling, notice that moving parts like to go together a particular way. There is enough slop in screws that an imperceptible twist in a part can cause a great deal of binding. Find the point where there is little or no binding at every opportunity. Even tightening screws in a certain order can affect things. One screw a tenth of a turn too tight can bind things up. On this the crosshead liked to go one way but the other was just slightly harder to crank.

On final assembly, after a complete cleaning, I lube with Mobil 1 straight 20w synthetic oil. Just a touch is all it takes, maybe two or three drops on the whole engine.

Thanks Bob.

Yeah, it's amazing how smoothly it just ticks over. Mesmerizing.

Thanks Zee.

You do really good work, so stop being so down on yourself. I'll bet you can do it with your engines right now.

The key is to reduce friction. For me, that means a proper break-in period. On this engine when I had finished the cylinder, crank, rods and guide I started running everything using the lathe to turn the crank. The engine probably had 5 hours of running before air even touched it. Oh, and I use lots of crappy oil. I use 3-in-1 for break-in purposes. It does lubricate, but mostly it's to flush out the ultra-fine chips from the break-in. There were also a couple complete tear-downs and thorough cleaning in alcohol.

When assembling, notice that moving parts like to go together a particular way. There is enough slop in screws that an imperceptible twist in a part can cause a great deal of binding. Find the point where there is little or no binding at every opportunity. Even tightening screws in a certain order can affect things. One screw a tenth of a turn too tight can bind things up. On this the crosshead liked to go one way but the other was just slightly harder to crank.

On final assembly, after a complete cleaning, I lube with Mobil 1 straight 20w synthetic oil. Just a touch is all it takes, maybe two or three drops on the whole engine.

Thanks Bob.

Yeah, it's amazing how smoothly it just ticks over. Mesmerizing.

Kevin, I didn't mean it was a very loud sound. I came across as a little phht phht phht sound with my volume set at a normal level. Watching it again with the volume all the way up it sounds a bit more like a tic tic tic. Laptop speakers aren't great.

What ever it is, sure runs nice! I'm likin' it.

Dean

What ever it is, sure runs nice! I'm likin' it.

Dean

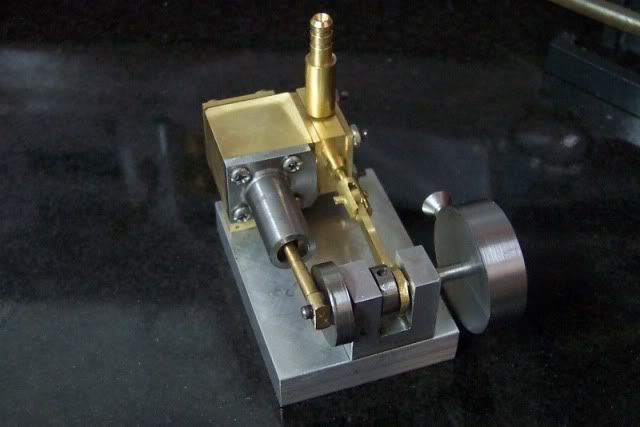

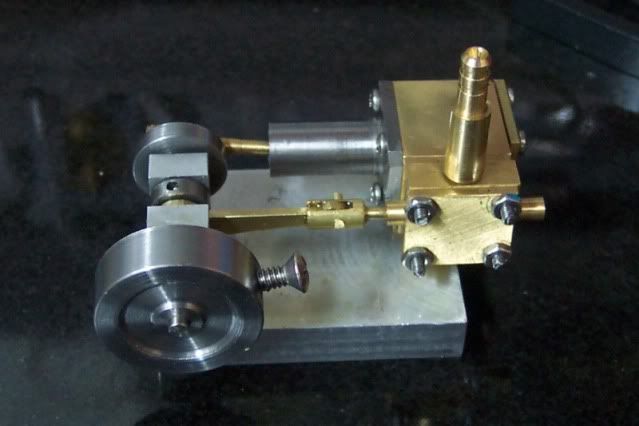

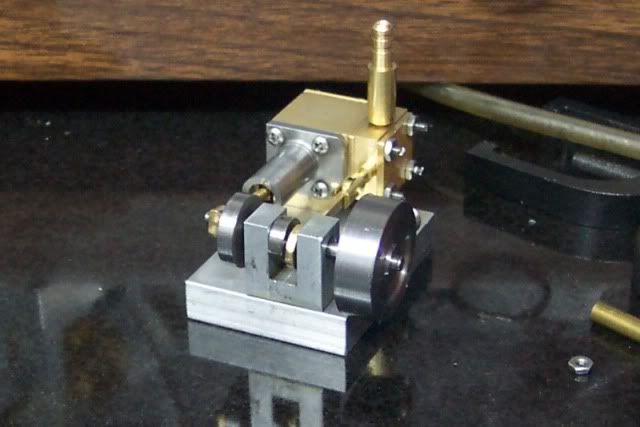

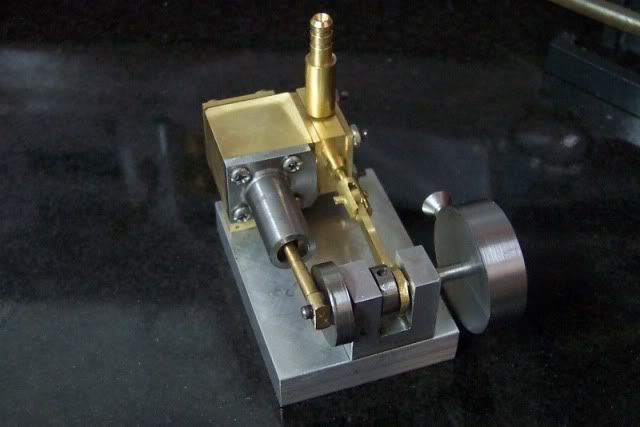

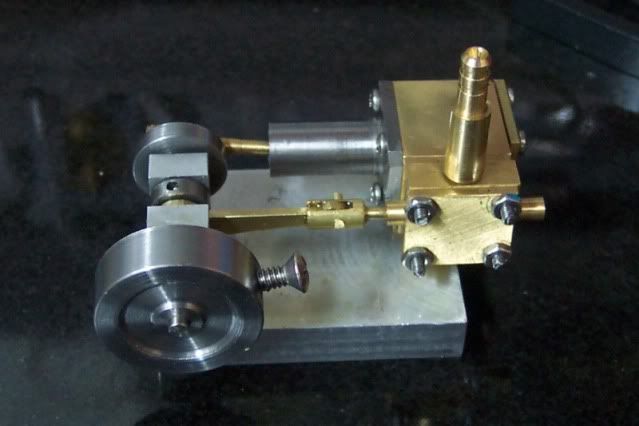

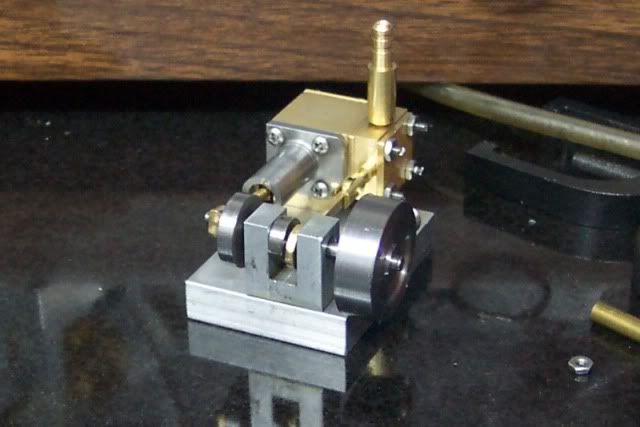

As promised here are some beauty shots. "Mr. DeMille, I'm ready for my close up".

It's not really ready for public consumption just yet. There are still some little details that need to be cleaned up. Overall I'm very pleased with the way it runs, especially at slow speed.

It's not really ready for public consumption just yet. There are still some little details that need to be cleaned up. Overall I'm very pleased with the way it runs, especially at slow speed.

Well, my wife talked me into getting a video camera. Yes, it was her idea!

So, here is a much better video of the engine running. It's still on an aquarium air pump, I added an inline valve to control the air flow. To get an idea of how small this is I've added a credit card sized gift card to the picture.

I still have a couple little details to attend to, but I'm calling it finished. Time to clean up the shop and move on to the next projects.

By the way, try it in full screen mode.

So, here is a much better video of the engine running. It's still on an aquarium air pump, I added an inline valve to control the air flow. To get an idea of how small this is I've added a credit card sized gift card to the picture.

I still have a couple little details to attend to, but I'm calling it finished. Time to clean up the shop and move on to the next projects.

By the way, try it in full screen mode.

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

Wow. It's smaller than I'd thought. Very cool.

Congratulations again.

I hope I can do as well with a piston/cylinder fit.

Congratulations again.

I hope I can do as well with a piston/cylinder fit.

Even better the second time around, Kevin. Truly a fine running engine.

I kind of hate to ask a camera question, but I've never seen a full screen vid this good. What kind of videocam did the Mrs. make you buy?

Oh yeah... her idea? What a gal!

Dean

I kind of hate to ask a camera question, but I've never seen a full screen vid this good. What kind of videocam did the Mrs. make you buy?

Oh yeah... her idea? What a gal!

Dean

Thanks Zee. Don't fret too much. You do just fine. I've found that worrying about doing something bad very often creates the kind of situation you were trying to avoid. But, just follow your instincts, do what you know is the correct and safe thing to do, then things turn out right.

Thanks Dean. I'm extremely pleased with the way it runs. By the way, I finally got rid of the pan head screw tonight and have a real grub screw.

I'm really pleased with the camera purchase, I was worried about getting one of the new digital video cams since I know next to nothing about photography. I just don't have the eye for it, the art escapes me. Anyway, the camera is a JVC HD Everio, model GZ-HM200. I got it from Best Buy, it's a refurbished unit so you can only get it online. It's a little tiny thing but does 1080p High Def, though artifacts are visible when it's up on the wide screen.

Yes, the Mrs. is quite practical at times. Especially when it comes to tools. We have an old VHS-C camcorder, but with tape on the way out and a vacation coming up it was not much of a stretch for her to suggest a new video cam. I was the one that balked. I still have the receipt, but I think I'll keep her ;D

Sorry for the crappy pic, but it was hard to get a good shot with all the shiny chrome and black paint.

Thanks Dean. I'm extremely pleased with the way it runs. By the way, I finally got rid of the pan head screw tonight and have a real grub screw.

I'm really pleased with the camera purchase, I was worried about getting one of the new digital video cams since I know next to nothing about photography. I just don't have the eye for it, the art escapes me. Anyway, the camera is a JVC HD Everio, model GZ-HM200. I got it from Best Buy, it's a refurbished unit so you can only get it online. It's a little tiny thing but does 1080p High Def, though artifacts are visible when it's up on the wide screen.

Yes, the Mrs. is quite practical at times. Especially when it comes to tools. We have an old VHS-C camcorder, but with tape on the way out and a vacation coming up it was not much of a stretch for her to suggest a new video cam. I was the one that balked. I still have the receipt, but I think I'll keep her ;D

Sorry for the crappy pic, but it was hard to get a good shot with all the shiny chrome and black paint.

- Joined

- Jan 3, 2008

- Messages

- 2,085

- Reaction score

- 17

Kevin, great build thread and a very nice engine. Somehow this one escaped me earlier I am sorry to say....so may builds...so little time. The use of the M&M shows well how tiny it is. Congrats on a fine runner.

Bill

Bill

Similar threads

- Replies

- 57

- Views

- 9K

- Replies

- 6

- Views

- 3K