Okay--The Rupnow engine is up and running, I've cut a pair of miter gears, and now I'm almost bored. I think I have a two month engineering contract about to cut loose, but it hasn't happened yet. I've been thinking about a flame gulper engine. Everybody that builds them complains mightily about how hard it is to get them to run---yet everybody seems to get them running eventually. Research seems to claim that they can be almost totally made from aluminum except for the crankshaft and cam, they should probably have open ball bearings to reduce drag, and the piston should be made from bronze if possible to keep from galling the cylinder wall. What other secrets should I be aware of if I decide to build one?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FlameSucker

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

canadianhorsepower

Well-Known Member

- Joined

- Oct 22, 2011

- Messages

- 1,671

- Reaction score

- 324

Brian,

Get on your knee and Prays The Lord

Rof}Rof}Rof}

Get on your knee and Prays The Lord

Rof}Rof}Rof}

Luc--Generally I have to do that at some stage of just about every engine I build.--Its either that or turn to drink and loose women!!!

Cogsy

Well-Known Member

Having built a Jan Ridders design as my first engine, I can recommend graphite as the piston. It machines great (but dirty - use a vac as you turn it) and doesn't require lube to keep running. Very clean and almost eliminates fouling.

Beware though - getting my first set of I.C. valves to seal was nothing compared to getting my flame licker running!

Beware though - getting my first set of I.C. valves to seal was nothing compared to getting my flame licker running!

jwcnc1911

-jwcnc191

- Joined

- Mar 19, 2013

- Messages

- 603

- Reaction score

- 86

I used bronze for the cylinder and brass for the piston of mine. I got it running in a couple days worth of tinkering. Getting a good cylinder/piston fit and reducing friction is critical. I found about 70 degrees of cam timing where the engine would run.

Pick one out and go for it!

From what I understand the Ridders designs are more difficult. I'd say do a Duclos or similar.

Go for it!

Pick one out and go for it!

From what I understand the Ridders designs are more difficult. I'd say do a Duclos or similar.

Go for it!

Piston/cylider fit and valve sealing seem to be the most critical to bits to get right. Port closed duration I found to be just about perfect at 110°, but opening and closing the port needs to be quite abrupt.

I've made 2, both from scrap. The 1st has a bronze cylinder and an aluminium piston and will start 1st flick every time, even from a tea light! The 2nd has an aluminium cylinder and a titanium piston. This one needs a pre-heat before she'll run, but when she gets going she runs superb.

I've made 2, both from scrap. The 1st has a bronze cylinder and an aluminium piston and will start 1st flick every time, even from a tea light! The 2nd has an aluminium cylinder and a titanium piston. This one needs a pre-heat before she'll run, but when she gets going she runs superb.

Gedeon Spilett

Well-Known Member

How come you did not already built a flame sucker?

There is nothing more rewarding for such a small number of parts!

They are so funny to watch and listen too.

the two best mine have cast iron piston and steel cylinder, they run fairly well but lots of corrosion problems.

Dont build too small; in the 25 mm bore range is ok.

Have fun

There is nothing more rewarding for such a small number of parts!

They are so funny to watch and listen too.

the two best mine have cast iron piston and steel cylinder, they run fairly well but lots of corrosion problems.

Dont build too small; in the 25 mm bore range is ok.

Have fun

Woodster--Seeing as it was your post about the Zippo flame licker that inspired me, I will ask you--Is the one with the bronze cylinder and aluminum piston the same general design as the one you posted drawings for? Does it have to be pre heated before it will run? If I build an engine, I don't want to have to screw around with it for 15 minutes before I can run it.---Brian

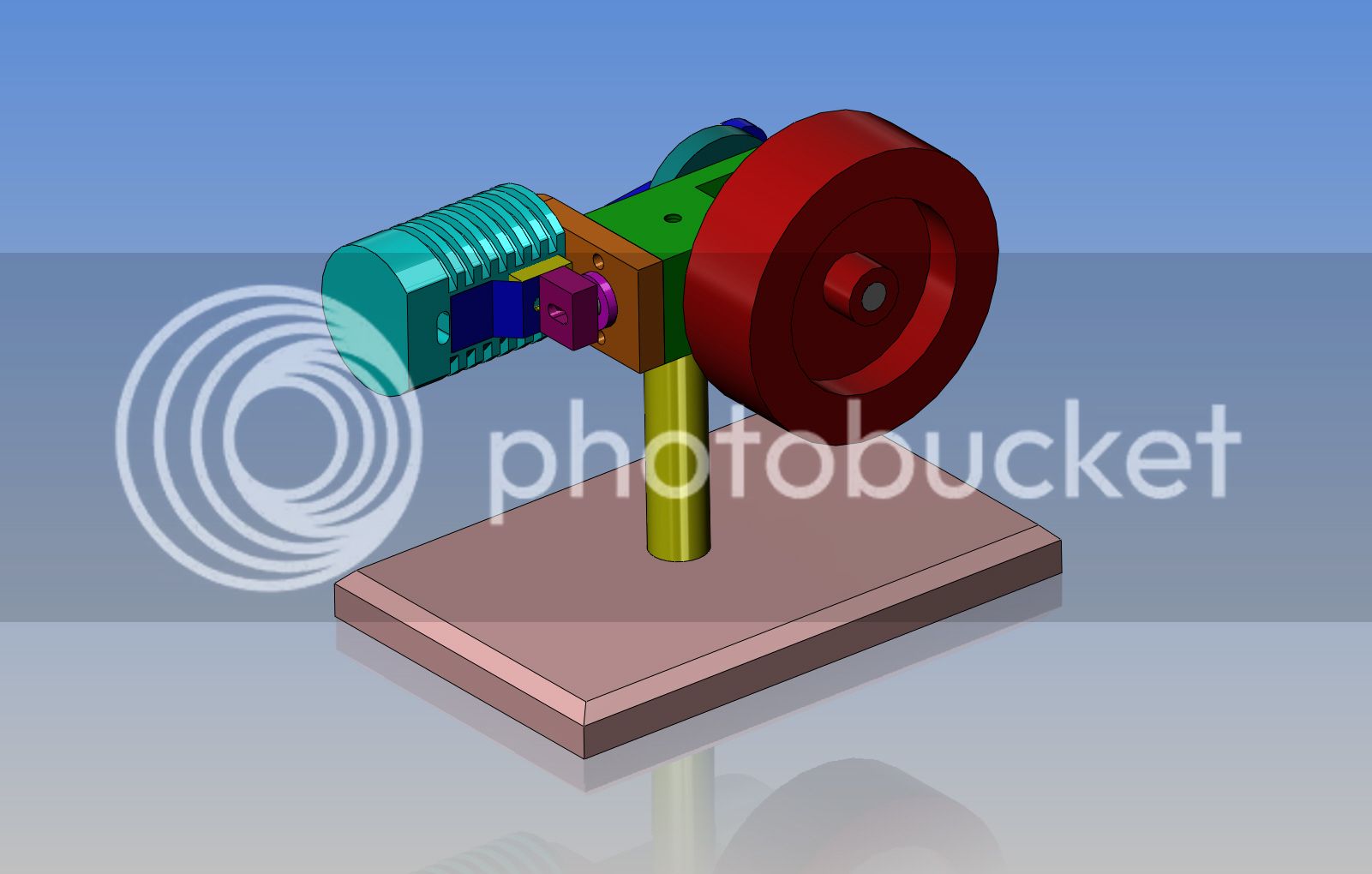

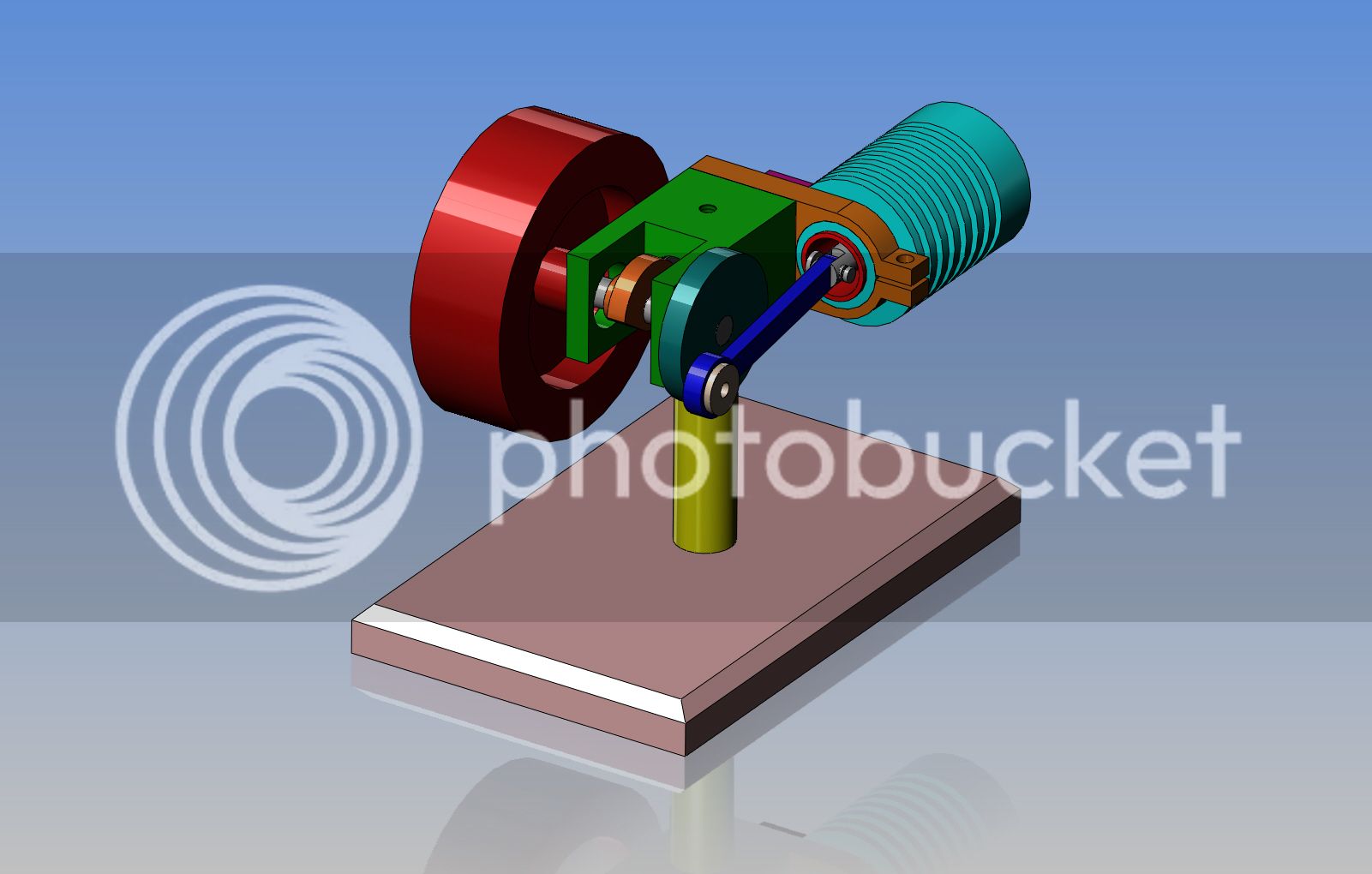

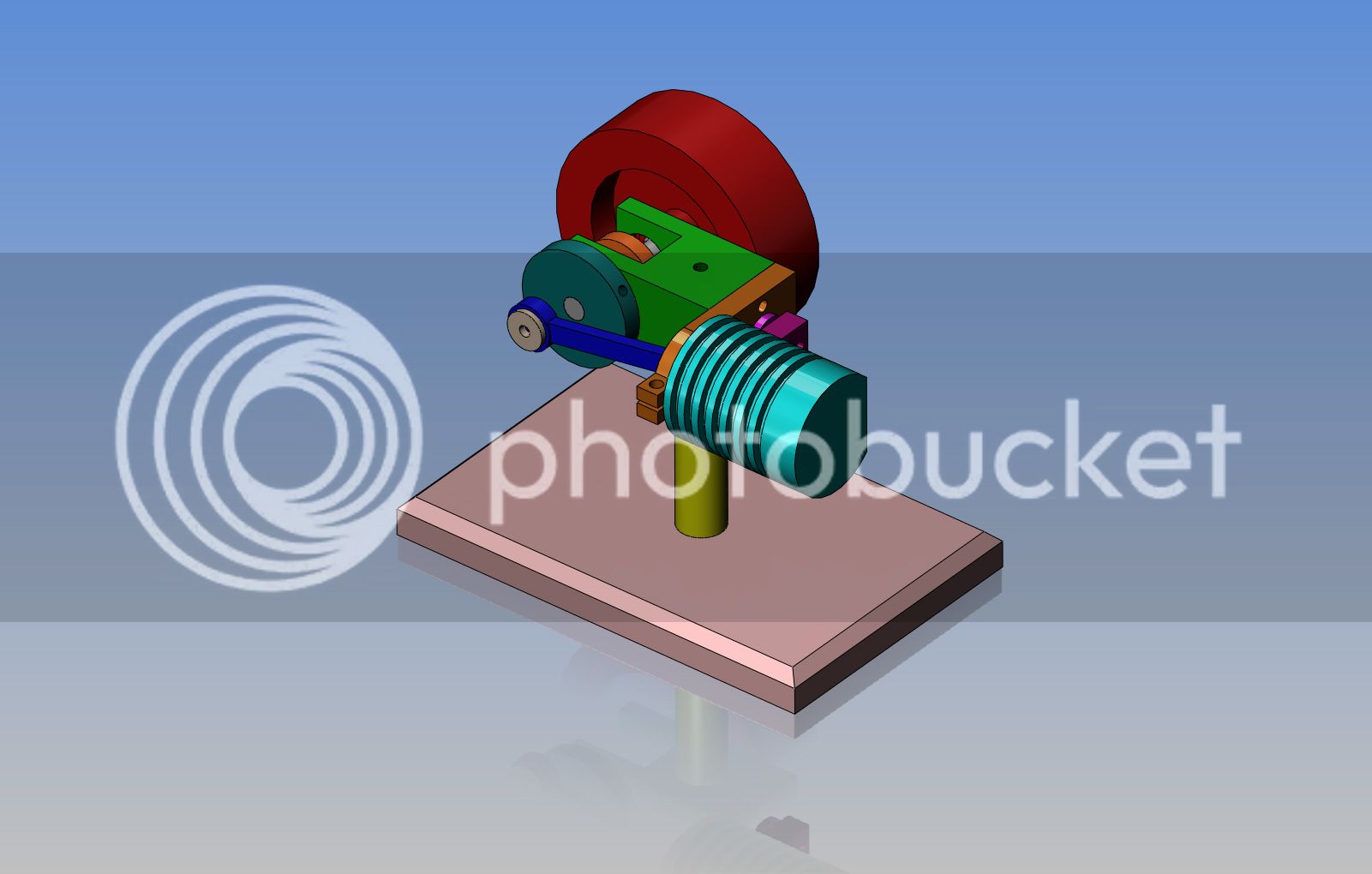

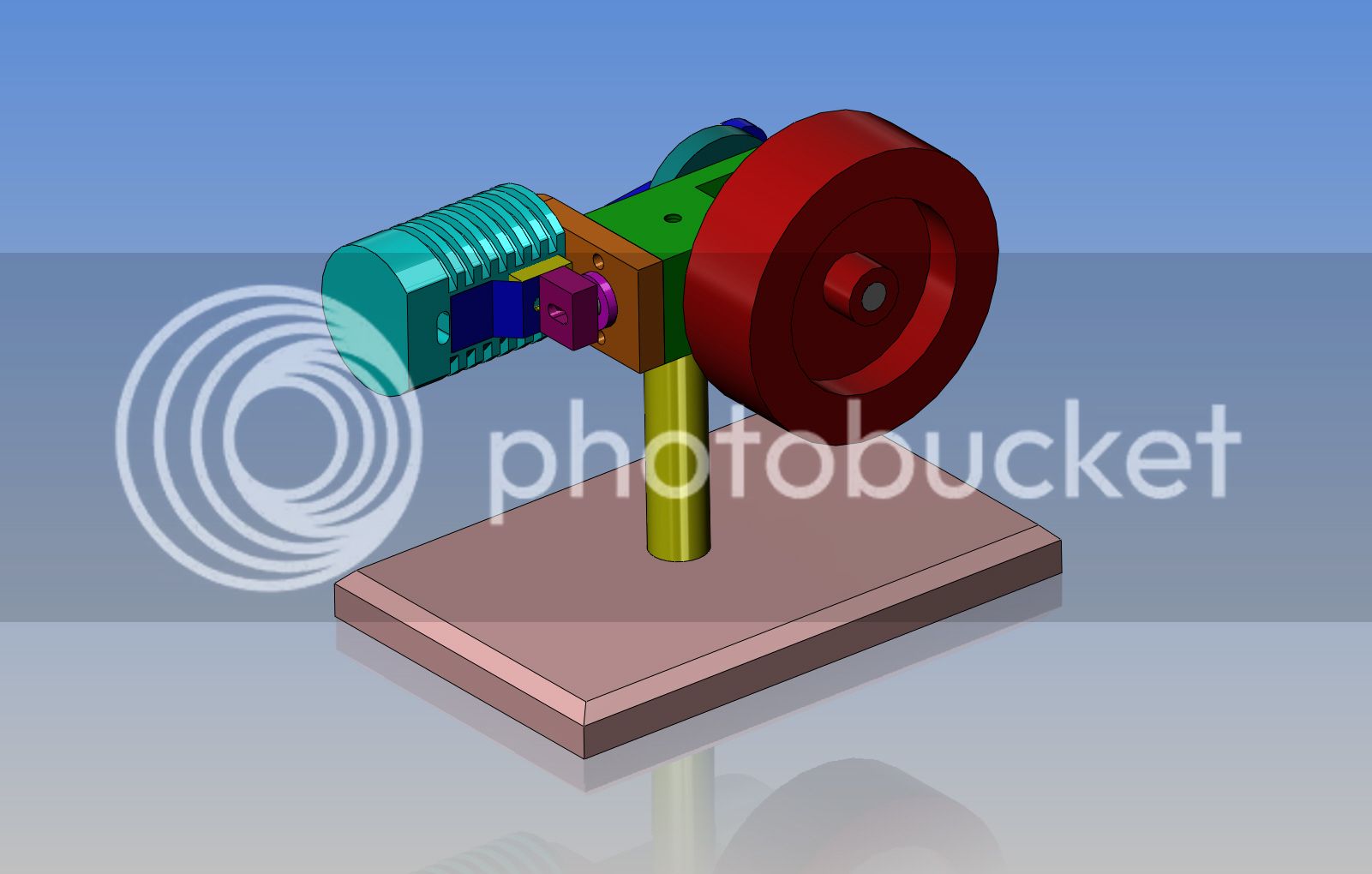

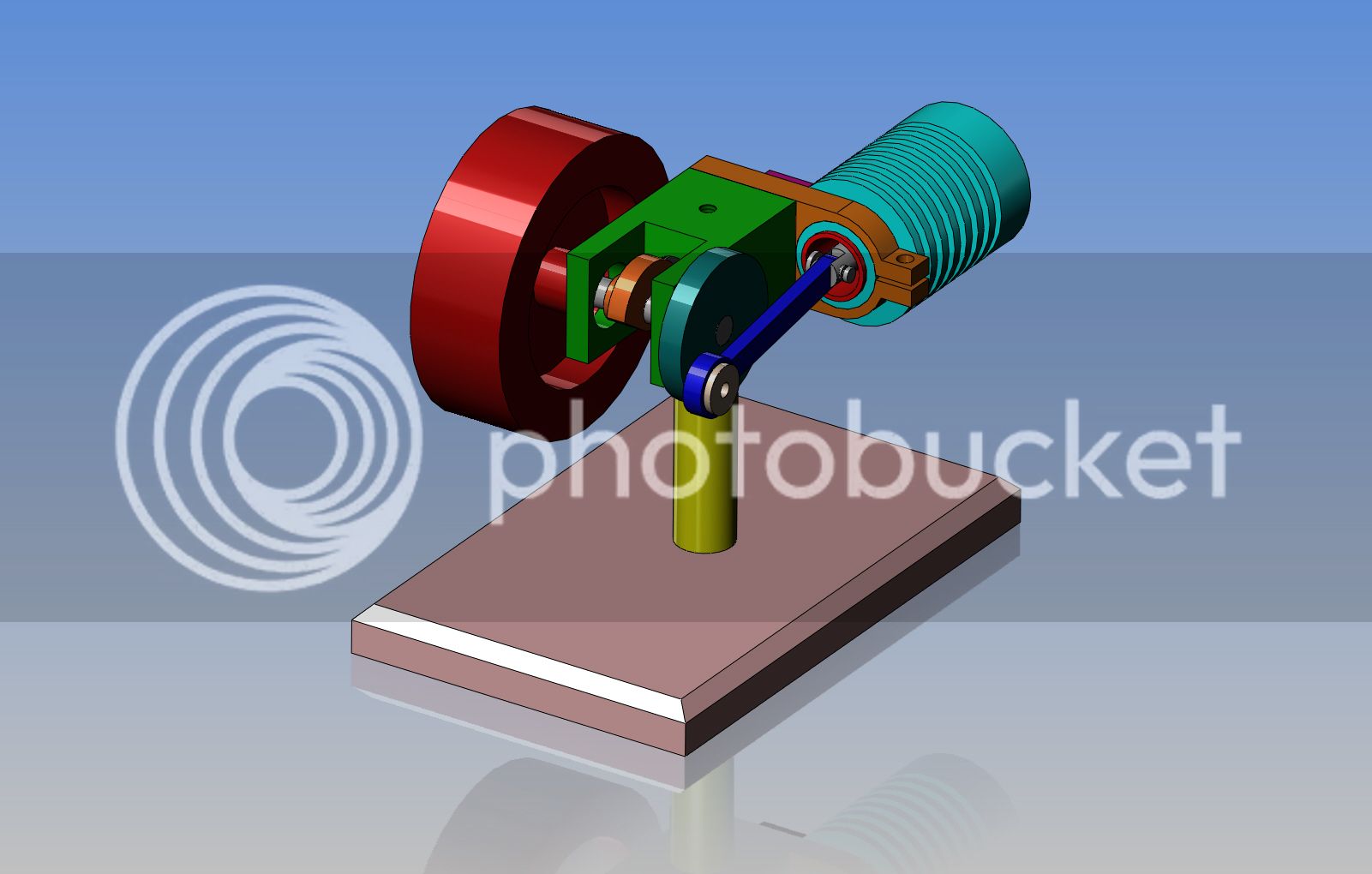

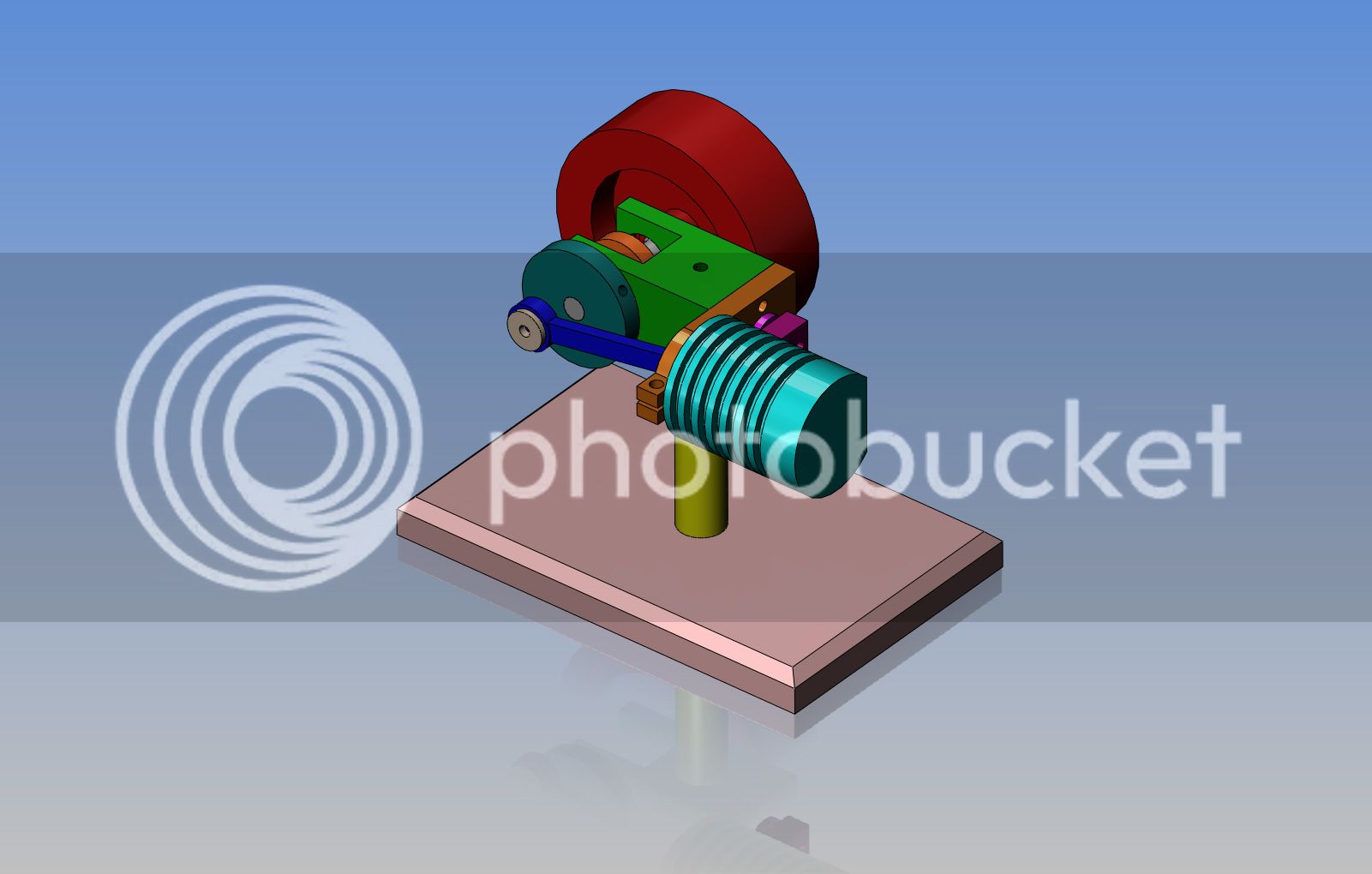

I have spent this afternoon modelling the Zippo flamelicker by Woodster http://www.homemodelenginemachinist.com/f12/metric-zippo-flame-eater-21762/ and this is what it looks like as a 3D model. Everything is still (at this stage) in metric, exactly as per Woodster's drawings. I haven't shown the bearings, because I lack some information regarding them. I am assuming that the con rod must have a shoulder bolt holding it to the crank disc.--And there's a spring in there somewhere but I haven't figured out quite where it goes yet, although I think it must hold the push-rod in contact with the cam.

- Joined

- Jun 4, 2008

- Messages

- 3,285

- Reaction score

- 630

My school CNC class did a run of 20, and got them all to run. We made the piston from brass and most of the rest from aluminum.

Steel parts were flywheel axle, cam follower, wrist pin, and the valve (spring steel). Also some steel screws, washers, and the valve spring. The crank arm (vs. the disc in your drawing) had a small brass plus as a balance weight.

The spring lies around the valve rod to give some aid in opening the valve and maintaining contact with the cam. I can post some pics if you like.

Cylinder was honed and lubricated with graphite power.

Steel parts were flywheel axle, cam follower, wrist pin, and the valve (spring steel). Also some steel screws, washers, and the valve spring. The crank arm (vs. the disc in your drawing) had a small brass plus as a balance weight.

The spring lies around the valve rod to give some aid in opening the valve and maintaining contact with the cam. I can post some pics if you like.

Cylinder was honed and lubricated with graphite power.

Last edited:

Hi Brian! Nice conversion.

I've answered you post in the plans thread, as far as pre-heat goes, i think it;s purely down to material choice and in my case, waiting for the Ti to get to a good temperature. With a Bronze/Ali combo you should be all good, although i prefer bronze cylinder and ali piston to try to lower the reciprocating mass. I found it a good experiment with Ti/Ali combo, but won't use it again.

Kvom, Thanks for your comments re crank. I designed this engine to be a simple as i could hence the very limited and simple milling ops required. I didn't use a mill or milling attachment, just a lathe with a 3 jaw chuck, lots of packing and "Inventive" workholding.

I've answered you post in the plans thread, as far as pre-heat goes, i think it;s purely down to material choice and in my case, waiting for the Ti to get to a good temperature. With a Bronze/Ali combo you should be all good, although i prefer bronze cylinder and ali piston to try to lower the reciprocating mass. I found it a good experiment with Ti/Ali combo, but won't use it again.

Kvom, Thanks for your comments re crank. I designed this engine to be a simple as i could hence the very limited and simple milling ops required. I didn't use a mill or milling attachment, just a lathe with a 3 jaw chuck, lots of packing and "Inventive" workholding.

Similar threads

- Replies

- 221

- Views

- 20K

- Replies

- 61

- Views

- 9K

- Replies

- 148

- Views

- 21K

- Replies

- 13

- Views

- 909