This week my lathe has been away being repaired, and I've been trying to think of what my next build will be. I can't finish my current engine until my lathe returns home. I don't feel like designing another engine until I finish the single cylinder vertical that I'm working on, and perhaps the v-twin. What I really wanted was a brand new design/build challenge, something I hadn't made before. Today I lay down for an afternoon nap, and when I woke up I had a bold new idea.---An electric starter system for model I.C. engines. This will be too expensive to make for any particular dedicated engine, but should in fact be suitable for all future builds. I must confess, I am a fan of Andrew Whale from the United Kingdom, a man who builds spectacular engines and posts very informative videos about building them. I have attached a link to Andrew's latest post, where he is building a dedicated electric start system for a Jerry Howell v-twin engine. Andrew chose to use a small, powerful electric starter motor from a motorcycle, which required a 12 volt battery and revved at about 18,000 rpm., requiring Andrew to build a gear reduction to get the rpm down to about 1000 rpm to start his engine. I have decided to use a 110 volt electric drill, which has a gear reduction built into the drill motor and since the drill motor rpm can be adjusted it will require no separate gear train. Being 110 volt, it will require no battery. For switching, a push button "momentary contact" switch should be all the control that is required. The drive will consist of two equal size toothed pulleys, a toothed belt, and a pair of "over-running" clutch bearings that will allow the motor to drive the engine, but will not allow the engine to drive the motor after it has started. This is a brand new project and I am excited about it. Tomorrow I will check the local hardware stores and pawn shops for a 3/8" variable speed electric drill, and contact McMaster-Carr about toothed pulleys and belts. Stay tuned---this should be interesting.---Brian

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Electric Starter System for Model Engines

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Oct 1, 2010

- Messages

- 1,377

- Reaction score

- 414

Brian,

I definitely will be watching this one. I like the way you engineer and document your projects.

--ShopShoe

I definitely will be watching this one. I like the way you engineer and document your projects.

--ShopShoe

The first 10$ of the Rupnow fortune has been spent on a 3/8" variable speed reversible drill, from the local buy and sell adds. I've spent the rest of the morning checking out timing belt pulleys and over-running clutch bearings from mechanical hardware catalogues.

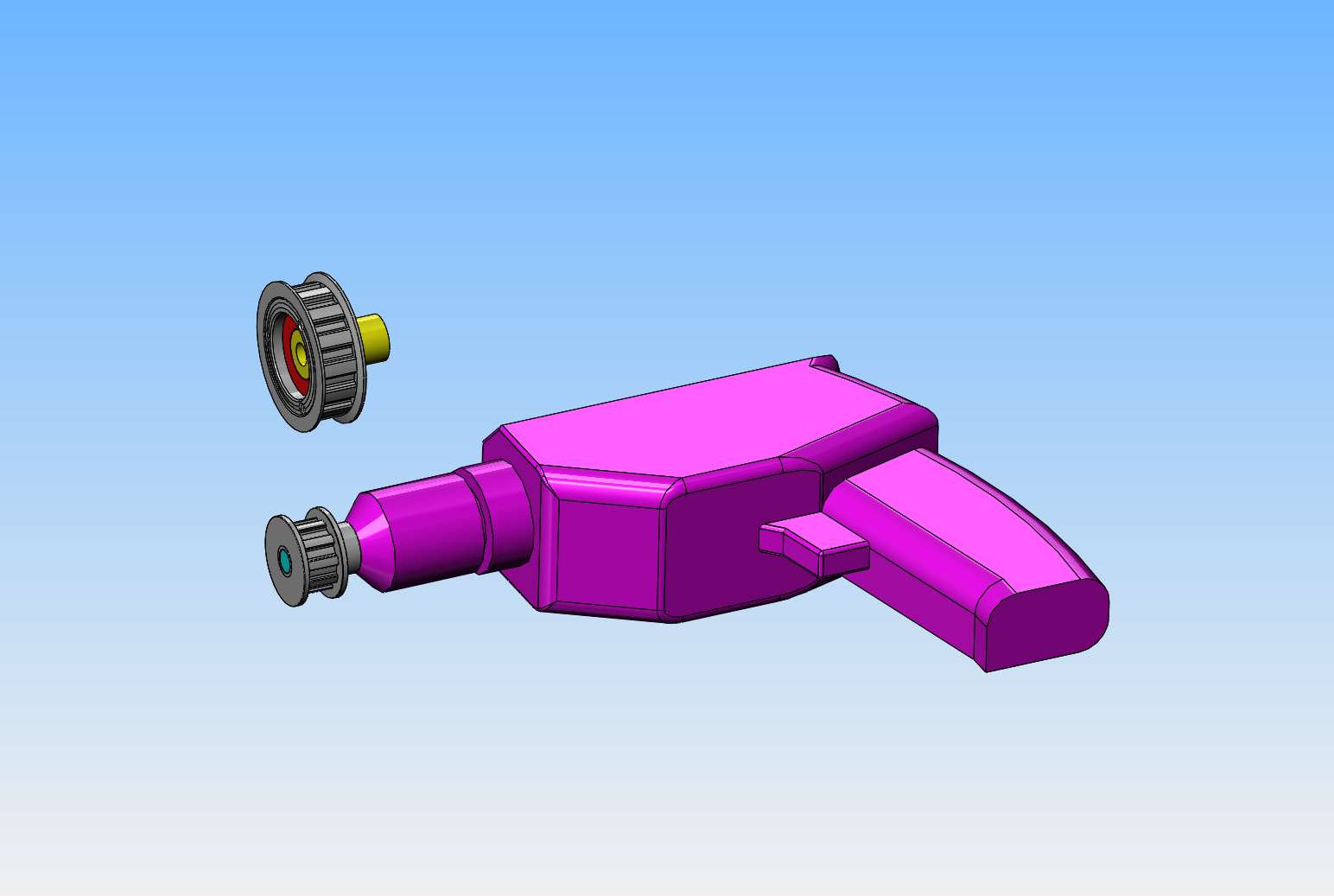

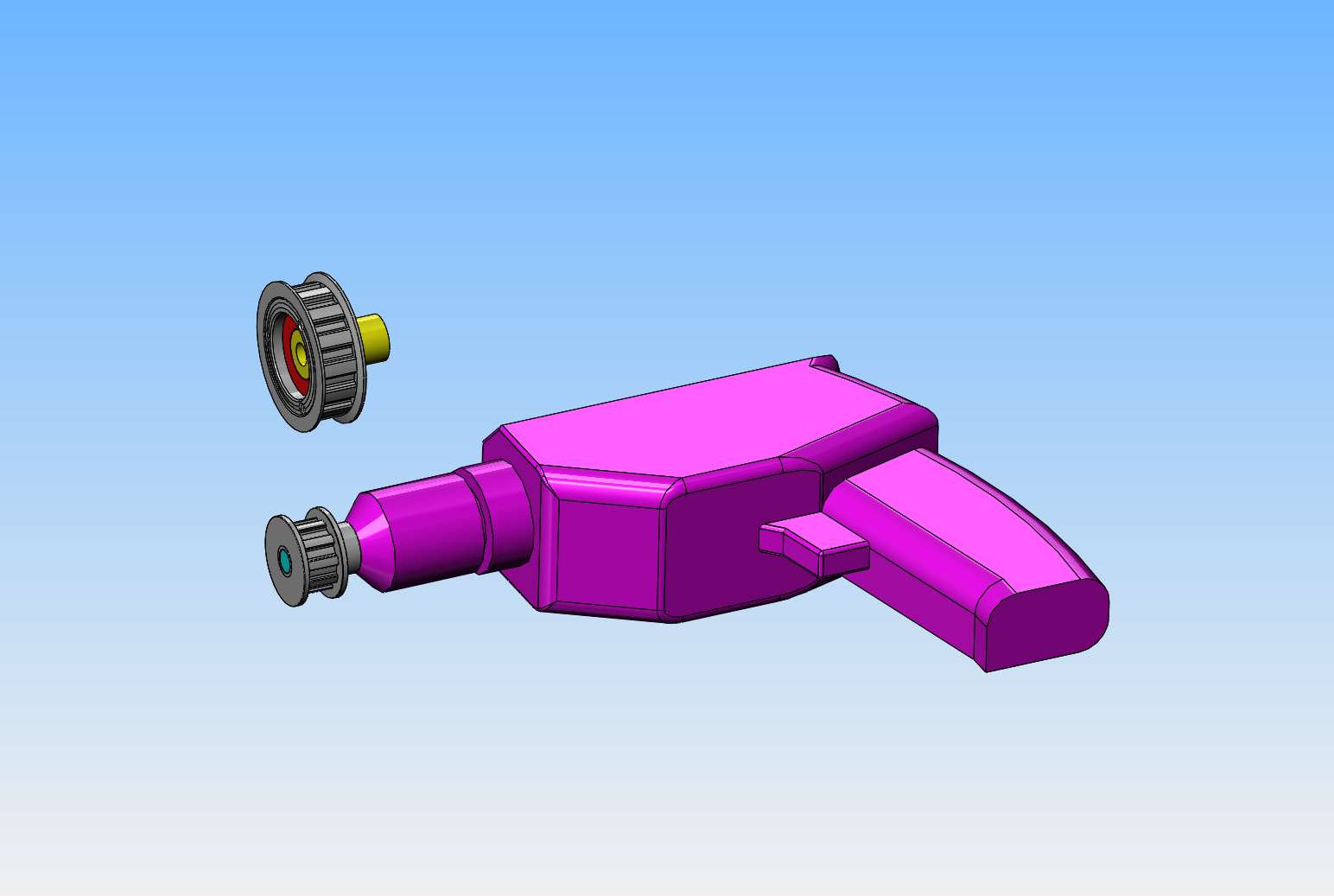

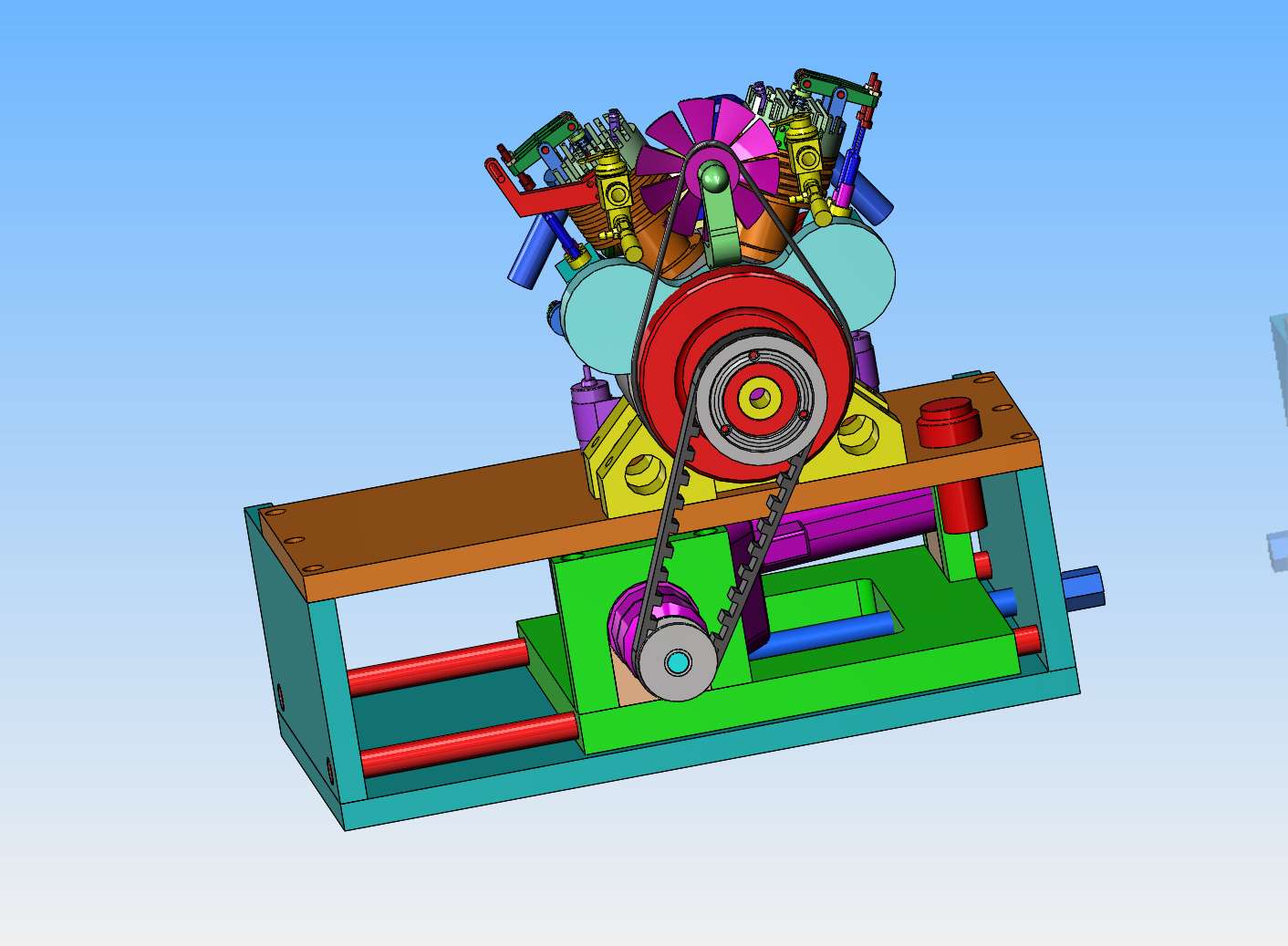

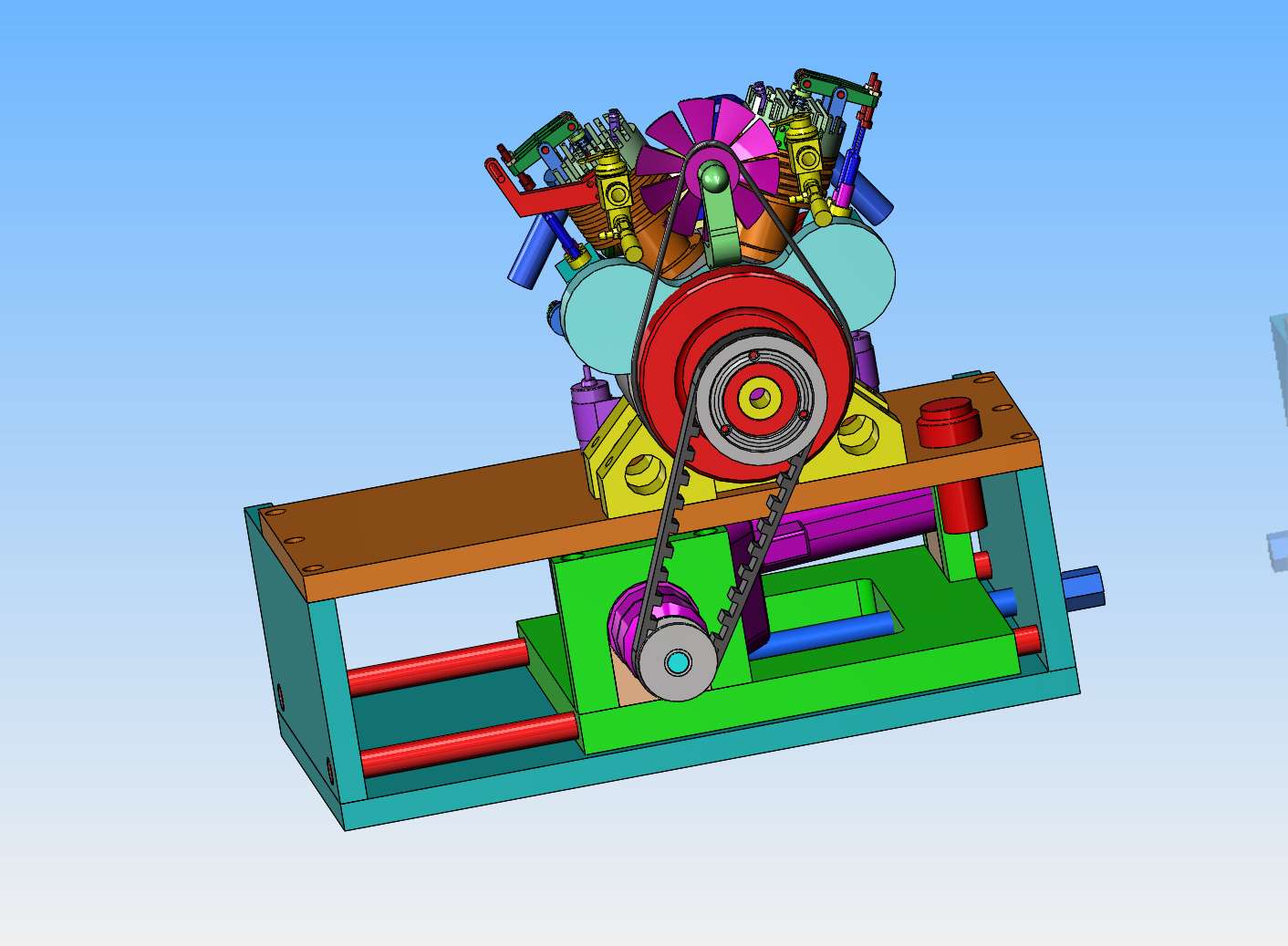

So, with two downloaded pulleys from McMaster Carr and two adapter shafts which I will machine, and a rough 3D model of the drill I purchased, this is what it looks like so far. I don't yet know what the shaft centers will be, so I haven' selected a belt yet. I may machine an adjustable take up pulley which I can adjust to vary the shaft centers to accommodate different engines--I'm not sure about that yet.

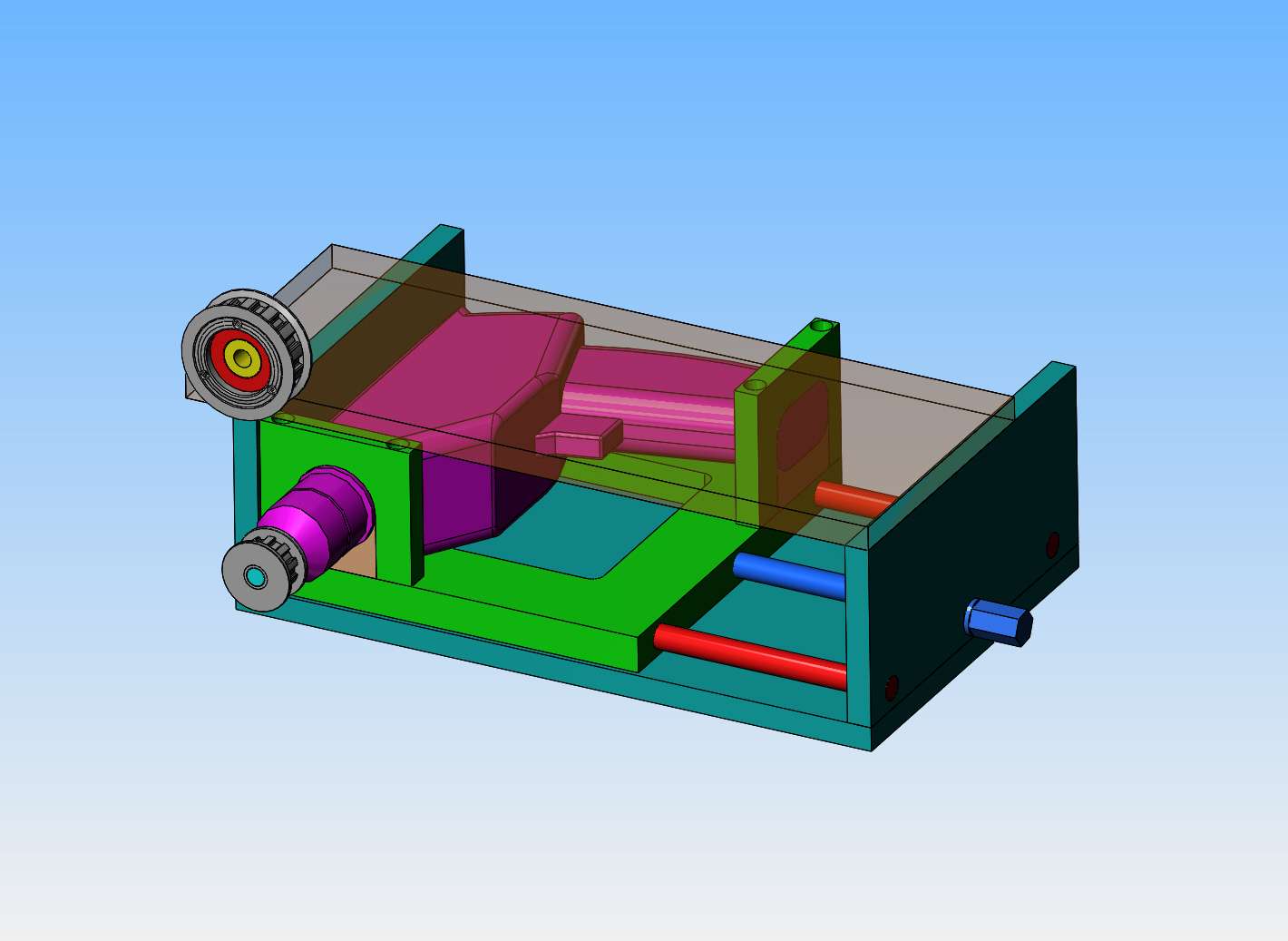

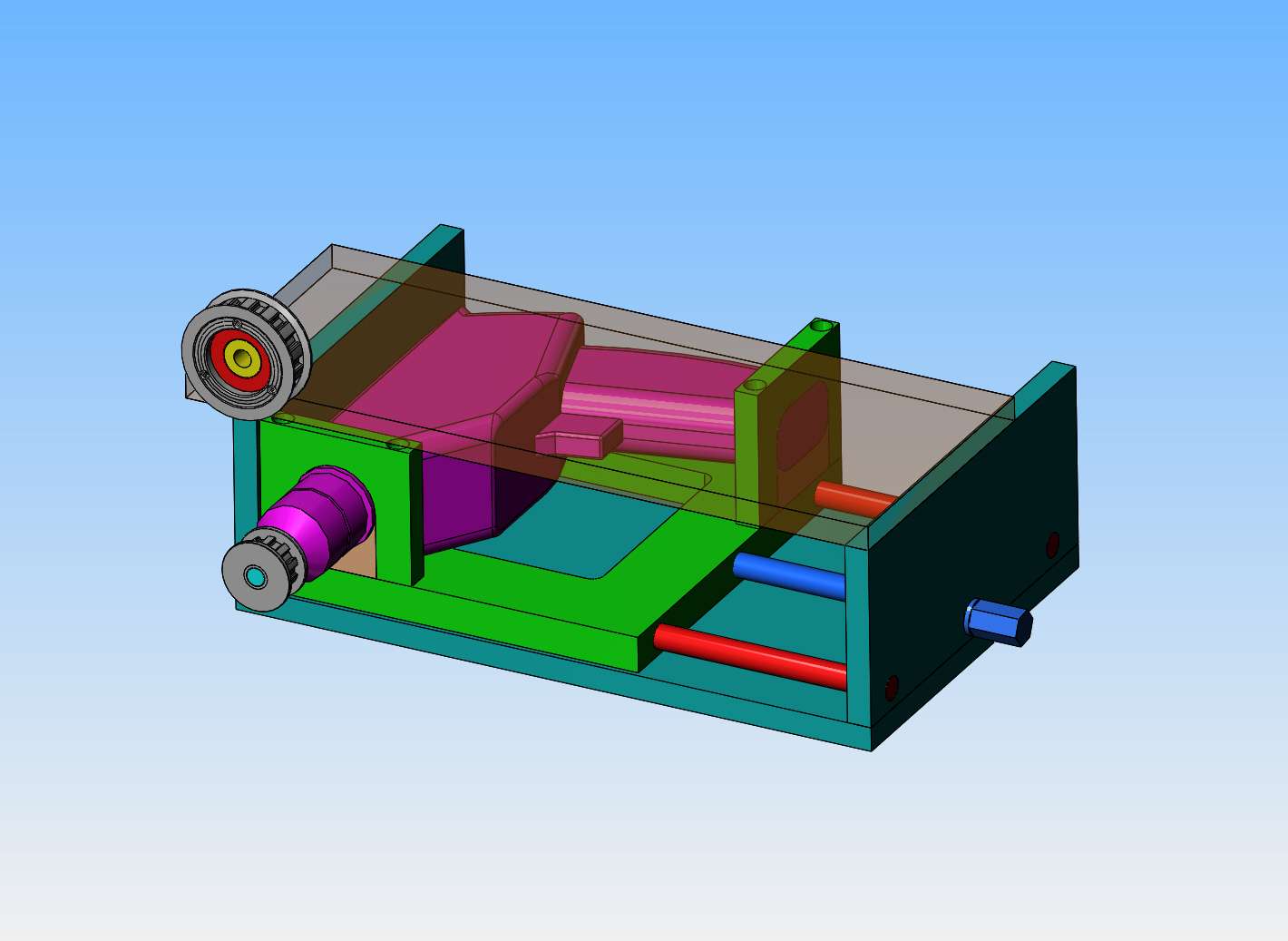

So, there it is, and there's really not that much to it. The carriage which the drill is mounted to is supported on two 1/2" diameter rods and can slide from end to end of the darker blue supporting structure, a total of 4 1/2". This means that I can change the center distance of the pulleys to fit any of my engines The blue rod in the center is threaded 1/2"-13 and the carriage supporting the drill is tapped 1/2"-13 on one side. This does away with the need for a third "tensioning pulley". I just ordered the over-running clutch bearing from Canadian Bearings and it cost $90---Ouch ouch ouch!! Now I will attempt to order the timing belt pulleys and belt from McMaster Carr---I'll let you know what that costs when I find out.

oldengineguy

Well-Known Member

Brian :Try Bearings Canada for one way bearings . They are much cheaper, and mail from Toronto. I got two 3/8 by 1/2 bearings for $35 plus HST plus mail $51.91 total. Google them . (I don' t have any affiliation with them) Colin

AndrewW

Well-Known Member

This week my lathe has been away being repaired, and I've been trying to think of what my next build will be. I can't finish my current engine until my lathe returns home. I don't feel like designing another engine until I finish the single cylinder vertical that I'm working on, and perhaps the v-twin. What I really wanted was a brand new design/build challenge, something I hadn't made before. Today I lay down for an afternoon nap, and when I woke up I had a bold new idea.---An electric starter system for model I.C. engines. This will be too expensive to make for any particular dedicated engine, but should in fact be suitable for all future builds. I must confess, I am a fan of Andrew Whale from the United Kingdom, a man who builds spectacular engines and posts very informative videos about building them. I have attached a link to Andrew's latest post, where he is building a dedicated electric start system for a Jerry Howell v-twin engine. Andrew chose to use a small, powerful electric starter motor from a motorcycle, which required a 12 volt battery and revved at about 18,000 rpm., requiring Andrew to build a gear reduction to get the rpm down to about 1000 rpm to start his engine. I have decided to use a 110 volt electric drill, which has a gear reduction built into the drill motor and since the drill motor rpm can be adjusted it will require no separate gear train. Being 110 volt, it will require no battery. For switching, a push button "momentary contact" switch should be all the control that is required. The drive will consist of two equal size toothed pulleys, a toothed belt, and a pair of "over-running" clutch bearings that will allow the motor to drive the engine, but will not allow the engine to drive the motor after it has started. This is a brand new project and I am excited about it. Tomorrow I will check the local hardware stores and pawn shops for a 3/8" variable speed electric drill, and contact McMaster-Carr about toothed pulleys and belts. Stay tuned---this should be interesting.---Brian

Hi Brian - thanks for the shout out.

Your solution looks good.

For info - I managed to find a geared motor on eBay. I've pinned the following description to my video explaining what I later did........

I decided to replace my starter motor with a geared version. This motor was suggested by Terry S (a fellow model engineer also building a JH v-twin) and can currently be found on eBay UK by searching for '3 bolt electric starter motor 50cc'. It cost less than £13 delivered! I made a bracket using 40mm angle iron with slots in the top for bolting to my aluminium base. The slots allow of belt tension adjustment. I kept the 48 tooth pulley on the engine end as it needs to be large enough for the sprag bearing. I put a 21 tooth pulley on the motor end using grub screws and epoxy resin to fix it. I also needed a larger belt 500mm long. This gets the rpm down to around 850. It works a treat! The only problem I encountered was the current draw. The original motor used less than 20A. The replacement blew that. I replaced with 25A and it blew that as well. So I ended up replacing the motor circuit 12AWG wiring with with 10AWG and using a 30A fuse. Fortunately the relay is rated at 30A. Very happy with the result and it's far quieter than my geabox version.

This week my lathe has been away being repaired, and I've been trying to think of what my next build will be. I can't finish my current engine until my lathe returns home. I don't feel like designing another engine until I finish the single cylinder vertical that I'm working on, and perhaps the v-twin. What I really wanted was a brand new design/build challenge, something I hadn't made before. Today I lay down for an afternoon nap, and when I woke up I had a bold new idea.---An electric starter system for model I.C. engines. This will be too expensive to make for any particular dedicated engine, but should in fact be suitable for all future builds. I must confess, I am a fan of Andrew Whale from the United Kingdom, a man who builds spectacular engines and posts very informative videos about building them. I have attached a link to Andrew's latest post, where he is building a dedicated electric start system for a Jerry Howell v-twin engine. Andrew chose to use a small, powerful electric starter motor from a motorcycle, which required a 12 volt battery and revved at about 18,000 rpm., requiring Andrew to build a gear reduction to get the rpm down to about 1000 rpm to start his engine. I have decided to use a 110 volt electric drill, which has a gear reduction built into the drill motor and since the drill motor rpm can be adjusted it will require no separate gear train. Being 110 volt, it will require no battery. For switching, a push button "momentary contact" switch should be all the control that is required. The drive will consist of two equal size toothed pulleys, a toothed belt, and a pair of "over-running" clutch bearings that will allow the motor to drive the engine, but will not allow the engine to drive the motor after it has started. This is a brand new project and I am excited about it. Tomorrow I will check the local hardware stores and pawn shops for a 3/8" variable speed electric drill, and contact McMaster-Carr about toothed pulleys and belts. Stay tuned---this should be interesting.---Brian

Interesting! I’m thinking about building a miniature inertia starter for a single cylinder model engine- need to figure out the gearing and flywheel weight.

Thank you Andrew--it's nice to hear from you. I'm off to the electric store this morning to see if I can buy a "momentary contact " (push button) switch for 110 volt drill.---Brian

The Rupnow fortune took another hit today. I went to my local electrical store and bought a "Momentary contact" switch--(in other words a push button switch) for the electric drill motor which will be my engine starter, for $33.00. They didn't have exactly what I wanted. I wanted a push button switch which was "off" when not pushed, "on" when pushed, spring loaded to "off" when I released it, and had the capability to push and turn so it would stay in the "on" position when I wanted it to. After much humming and hawing, they decided that they didn't have such a switch and couldn't get such a switch. I think that's a lot of baloney, so I just ended up with the push button switch shown.--If I really NEED the extra feature, I will machine a piece of steel which swings into place to hold the button in the "on" position.--Why would I want that?--Because some of my newly built engines don't start in the first 15 seconds of cranking.--I wanted to be able to lock the switch in the "on" position so I could make adjustments to the carburetor and ignition timing while the engine was still being cranked over---I wanted both hands free.

I have put electric start on most of my last few engines. I have used small motors from rechargeable drills available for a few dollars on ebay. Check the rpms, many different ones are out there. For bigger motors I used motor scooter starters from china, again cheap. Various sizes are out there. Even the small motors draw a surprising amount of current. Amazon has some really nice red and black,10 ga. silicon wire that's very flexible. I also use a motor scooter solenoid on all but the smallest starters. I have bought my one way bearings from Boca Bearing in FL. They have good prices and service. I have used 1/4" chain, g2 belts and 1/8" belts. All work but the 1/8" belts are prone to slip. Geared starters are kind of noisy in my experience.

A nice feature of the solenoid system is I can easily add a remote starter button. I set the starter button out in front of the model and let kids of all ages start the engine. They all seem to really enjoy it and feel somehow more involved.

A nice feature of the solenoid system is I can easily add a remote starter button. I set the starter button out in front of the model and let kids of all ages start the engine. They all seem to really enjoy it and feel somehow more involved.

Here's a better picture, in which I have shown the timing belt and pulleys and starter switch. The brown top plate will actually be drilled and tapped in a number of places to accommodate different engines, as this starter system is generic---it will fit all of my different i.c. engines.

Last edited:

- Joined

- Jul 8, 2009

- Messages

- 760

- Reaction score

- 234

Brian:

Would a 3 position selector switch work? You can get them in different configurations, spring-return to center, and maintained. Use the spring return side for your momentary run and the maintained side when you wanted it to run continuously. They'd also have the ampacity and voltage ratings you require. Try Automation Direct, they may seem a little cheesy, but I've seen more and more OEM equipment with their parts running the stuff - it'd be fine for a home shop.

Don

Would a 3 position selector switch work? You can get them in different configurations, spring-return to center, and maintained. Use the spring return side for your momentary run and the maintained side when you wanted it to run continuously. They'd also have the ampacity and voltage ratings you require. Try Automation Direct, they may seem a little cheesy, but I've seen more and more OEM equipment with their parts running the stuff - it'd be fine for a home shop.

Don

I don't see this as being too complex. It's not nearly as complex as making an engine.--Anyways, I get sick of building engines. I wanted something else to design and build. And, like I said, there are some times on a brand new engine that I'd like to have both hands free to adjust things while the engine is being turned over. No V8's for me Jerry--I'm happy with single and double cylinder engines. Designing this project has given me something interesting to do while my lathe was out being fixed.---My lathe came back from Toronto today, I picked it up from the local BusyBee tools outlet, brought it home, unloaded it from my truck about 2 minutes before the freezing rain started and now it's back in my machine shop.

Yowee!!!--I just priced out the aluminum for this job and it comes to $202.00 plus tax. That's a big hit. Let's see---10$ for drill, $90 for one way bearing, and I don't have a price on the timing belt pulleys and timing belt yet. I bet it will be $400 by the time I buy everything required. It's a good thing that I have enough magazine articles published to pay for this stuff. Of course, non of this is stuff Brian needs. It is all stuff that gives Brian something interesting to do and keeps him from being bored to death----and that's pretty important.

Could you make it out of wood or pressed wood?

Vietti--Maybe I could. I've already ordered the aluminum. I don't have a lot of luck with wood.

Where the starter is concealed in the box below the engine, all well and good.

When we build the engines with an intergral starter, we use the r/c model aircraft brushless motors.

I built up a control board using either Arduino pro mini or ATtiny85 to take care of all the necessary configuration of the esc, the latter being off the shelf aircraft gear as well.

Small size and powerful.....

When we build the engines with an intergral starter, we use the r/c model aircraft brushless motors.

I built up a control board using either Arduino pro mini or ATtiny85 to take care of all the necessary configuration of the esc, the latter being off the shelf aircraft gear as well.

Small size and powerful.....

Yikes, that's an outrageous price. You may already know this, but in case not, for future reference, it sounds like what you are wanting is what is generally called a push button latching switch - the latching part being the key word that indicates it is push on (stays on); push off. Do a search for "push button switch latching" on Amazon and you will get all sorts of options for way less cost. Here is one example, rated for 5a - not sure if that is enough for your drill, but if not, there are others with higher ratings: https://www.amazon.com/Gebildet-Prewired-Waterproof-Self-Locking-Stainless/dp/B095P1LGR3/The Rupnow fortune took another hit today. I went to my local electrical store and bought a "Momentary contact" switch--(in other words a push button switch) for the electric drill motor which will be my engine starter, for $33.00. They didn't have exactly what I wanted. I wanted a push button switch which was "off" when not pushed, "on" when pushed, spring loaded to "off" when I released it, and had the capability to push and turn so it would stay in the "on" position when I wanted it to. After much humming and hawing, they decided that they didn't have such a switch and couldn't get such a switch. I think that's a lot of baloney, so I just ended up with the push button switch shown.--If I really NEED the extra feature, I will machine a piece of steel which swings into place to hold the button in the "on" position.--Why would I want that?--Because some of my newly built engines don't start in the first 15 seconds of cranking.--I wanted to be able to lock the switch in the "on" position so I could make adjustments to the carburetor and ignition timing while the engine was still being cranked over---I wanted both hands free.

No affiliation, haven't bought this particular unit, and my apologies if I am saying things that you already know, or misunderstanding what kind of switch you are wanting!

Tried two of those and they melted with 12 Volts. Maybe ok at 110 volts. The small 12 V motors from drills etc draw a lot of current, maybe 30 amps.

Similar threads

- Replies

- 0

- Views

- 282

- Replies

- 12

- Views

- 1K