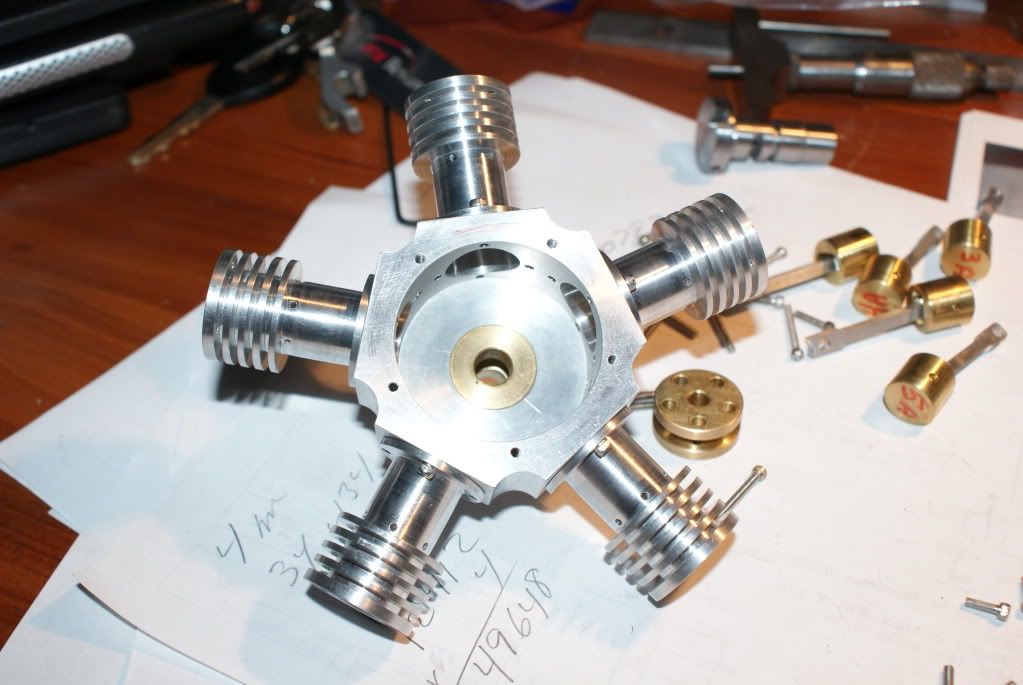

zeeprogrammer said:Looking good Dave.

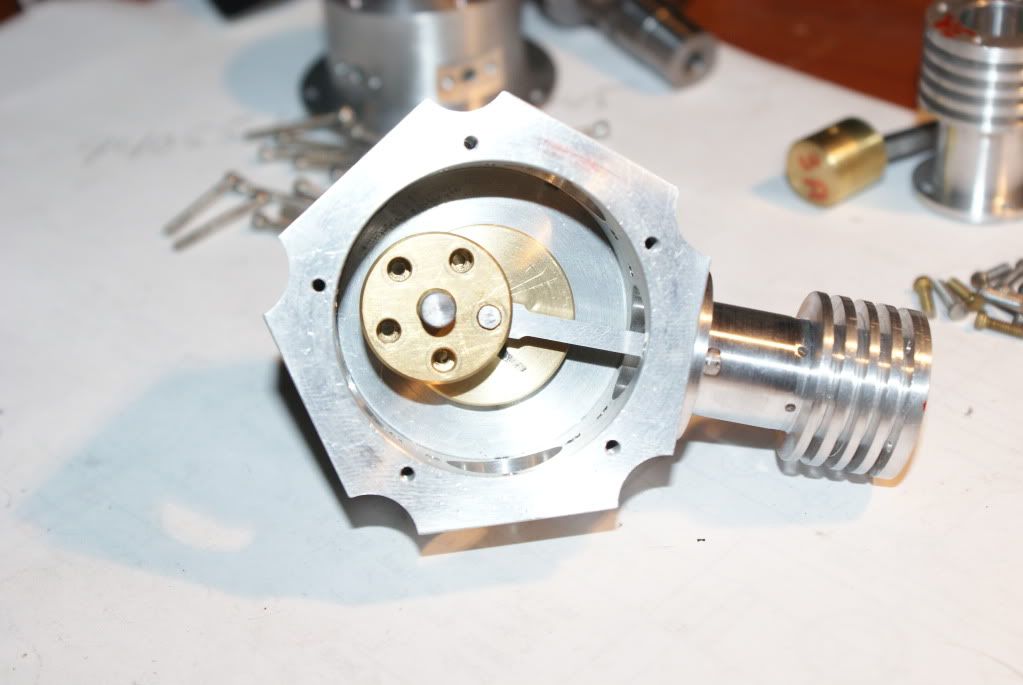

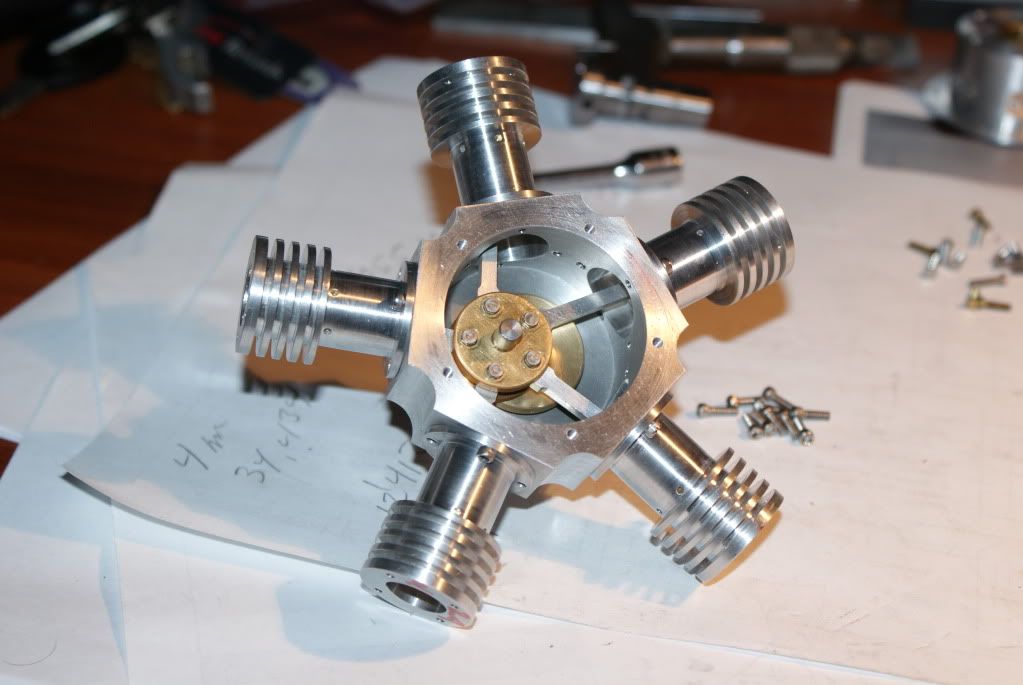

Is there a reason why the end of one of those rods is different from the others?

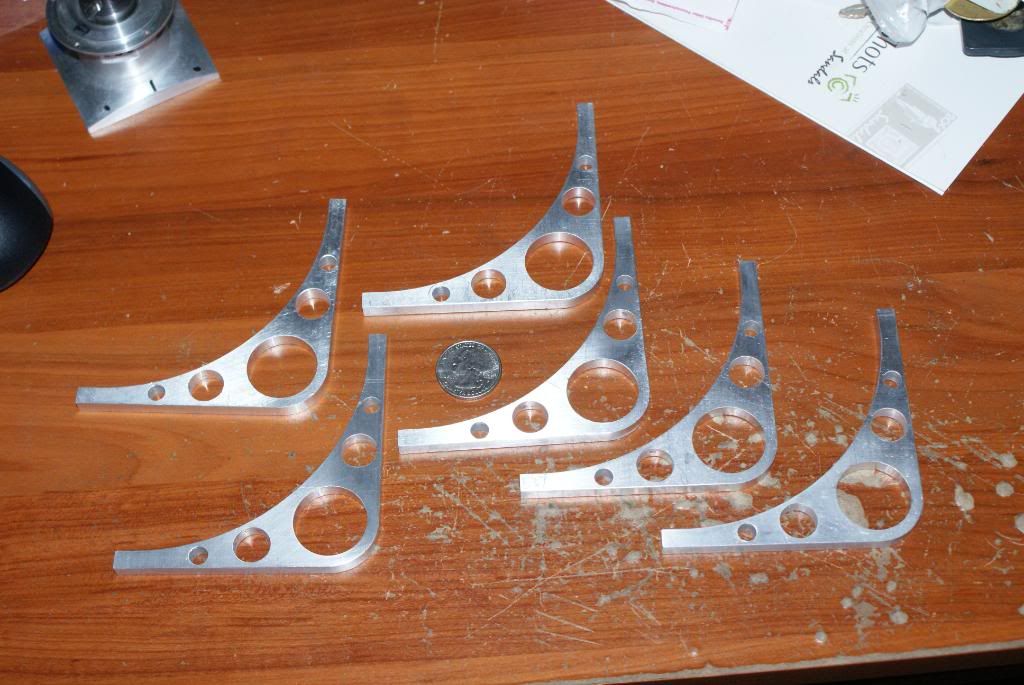

That rod must butt into the center of the crank disk to lock it in and create the master rod. Radial has to have a master rod.

zeeprogrammer said:Looking good Dave.

Is there a reason why the end of one of those rods is different from the others?

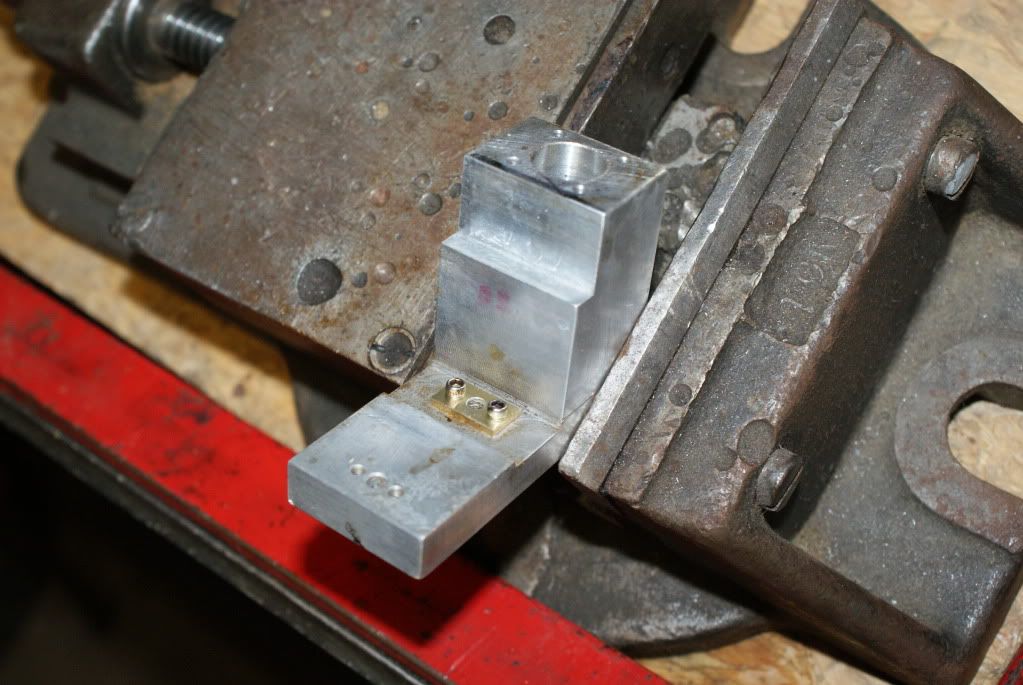

dreeves said:Did I mention I hate soldering.

Enter your email address to join: