- Joined

- Jul 29, 2008

- Messages

- 560

- Reaction score

- 62

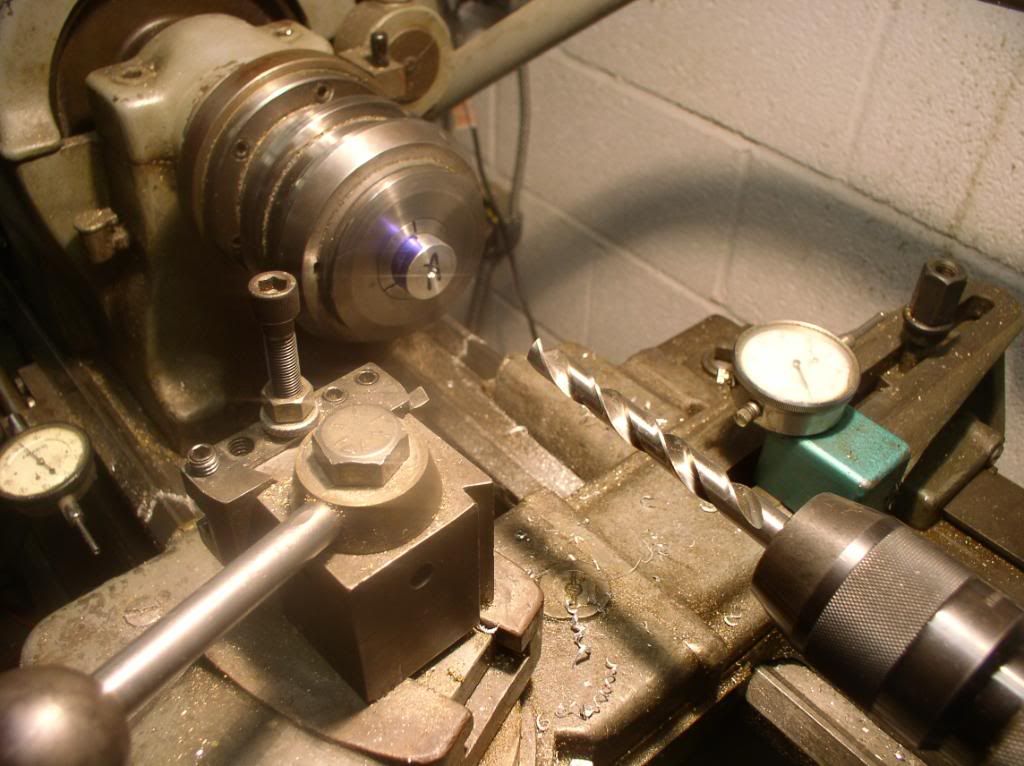

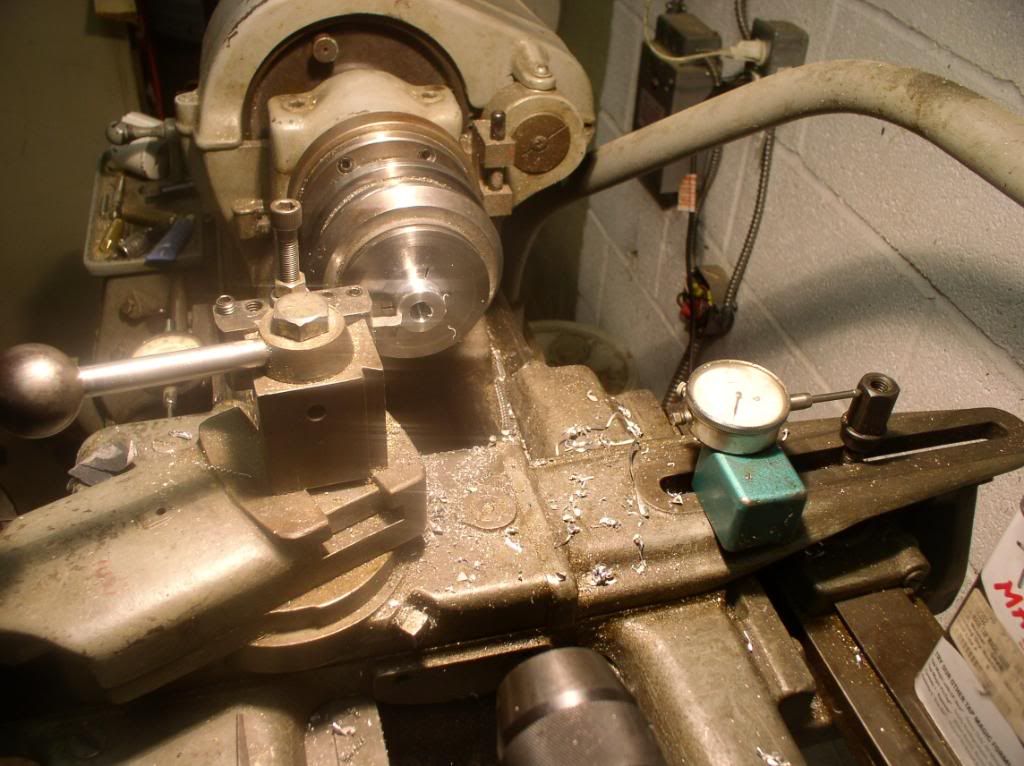

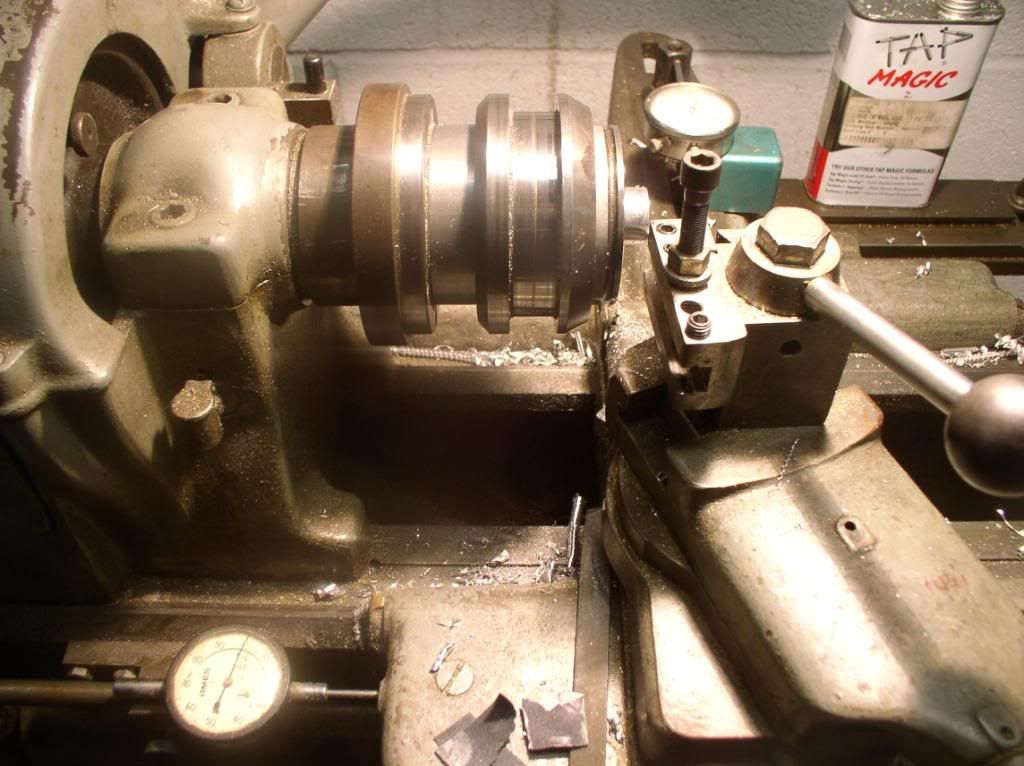

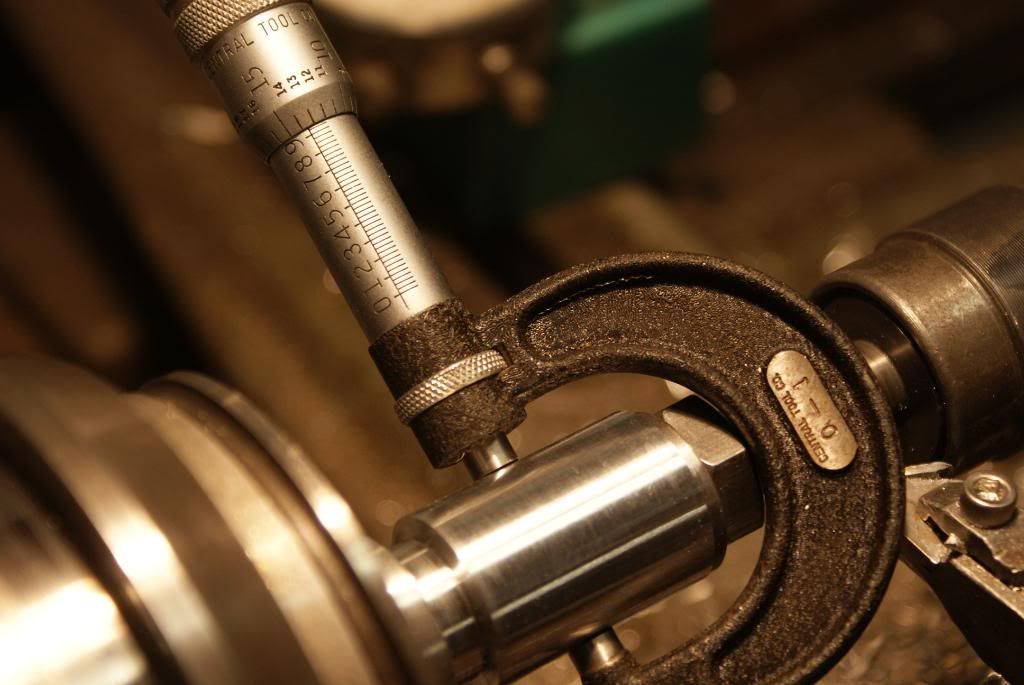

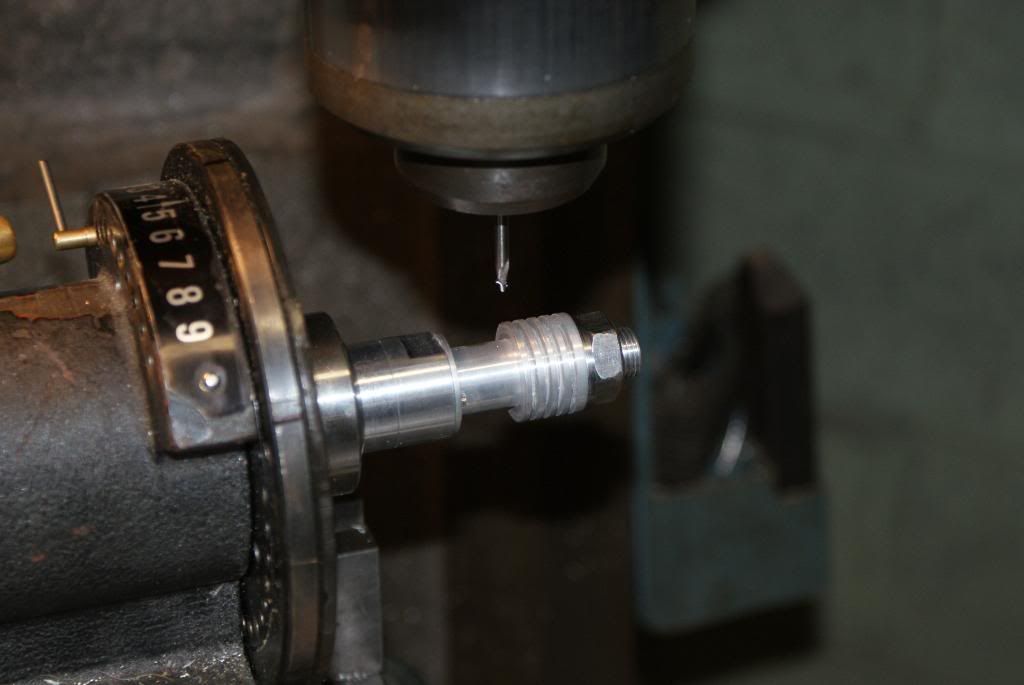

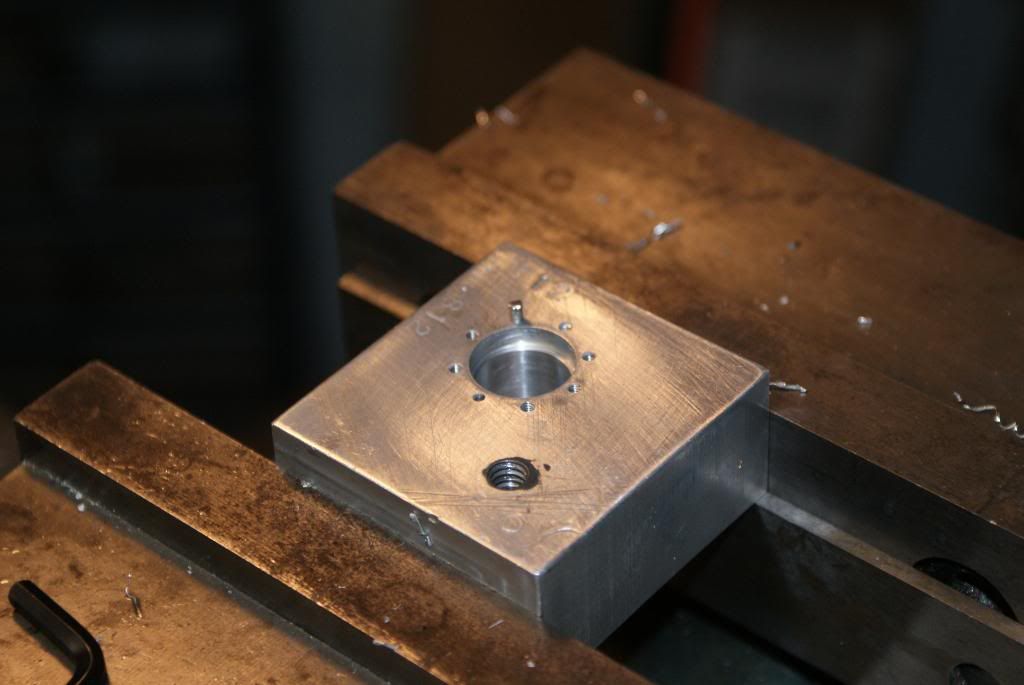

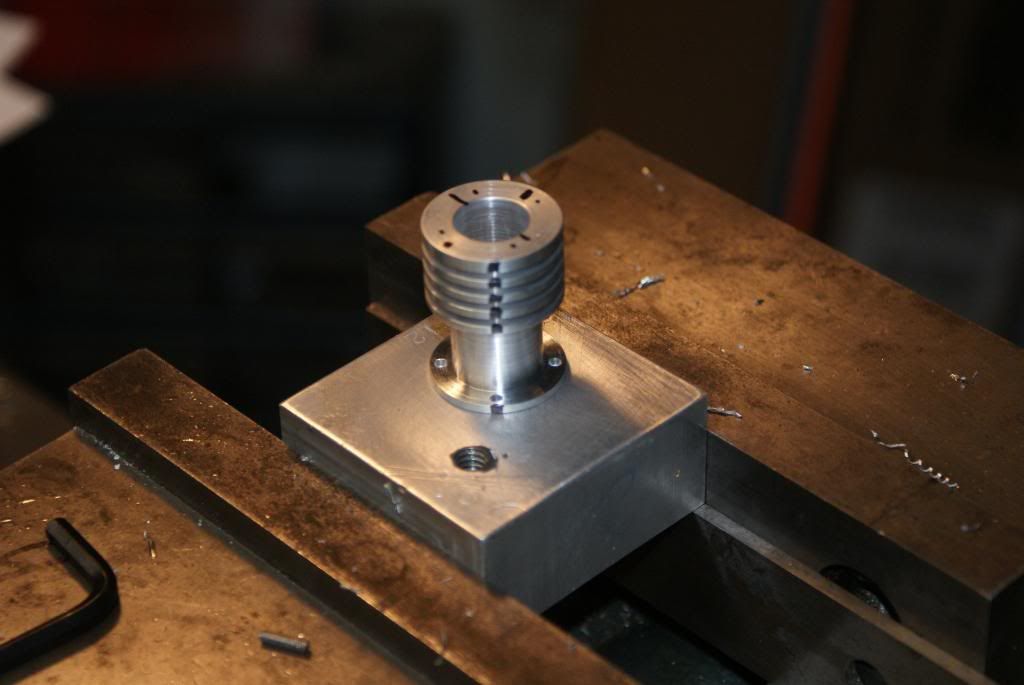

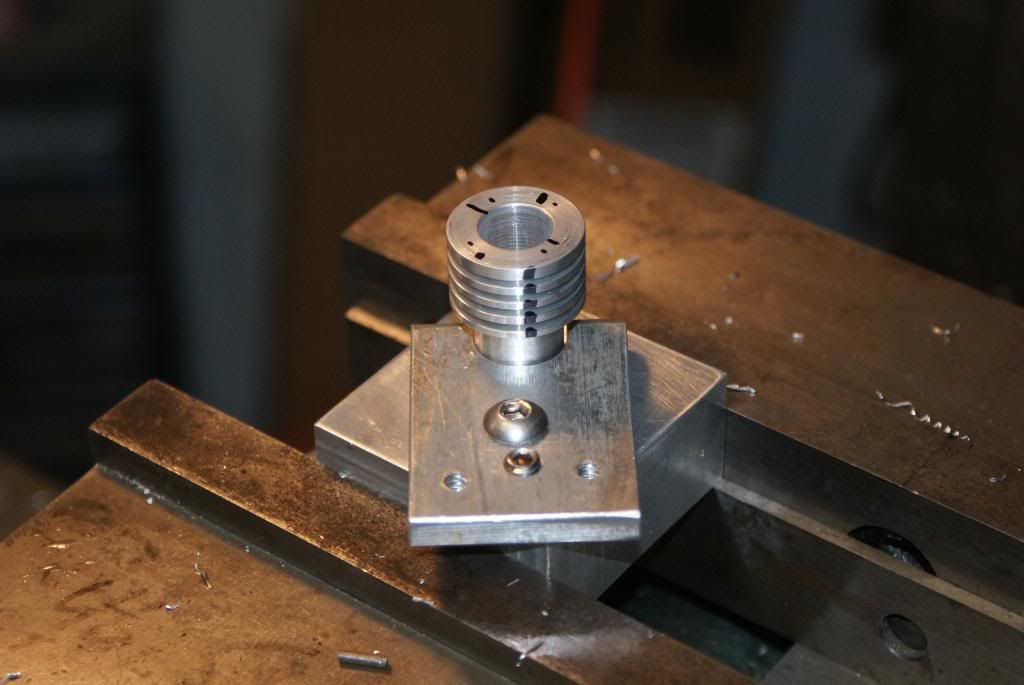

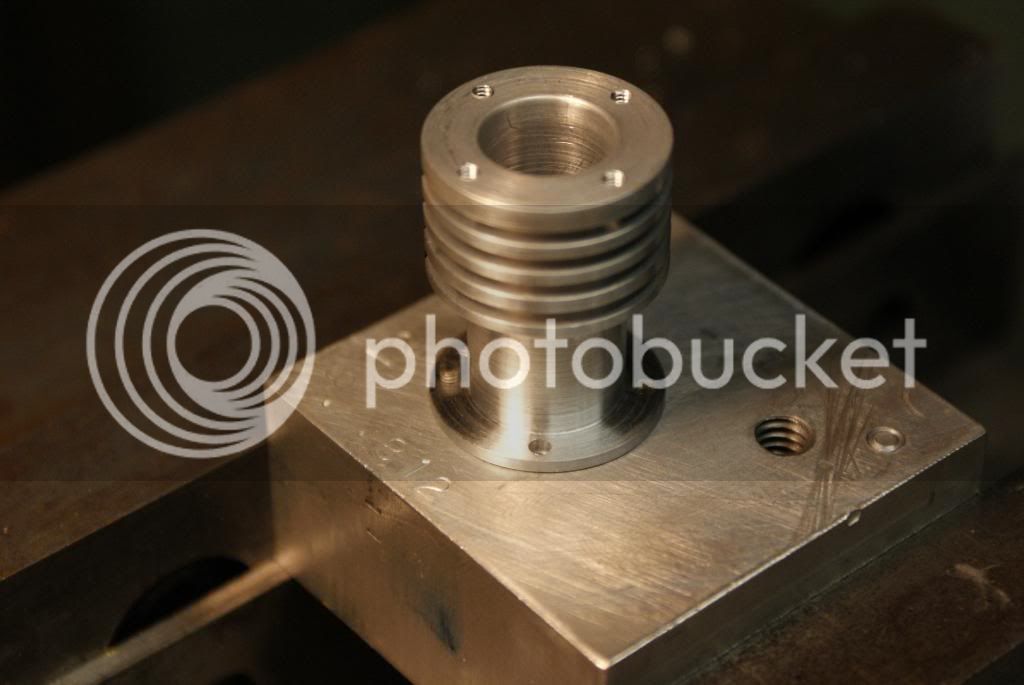

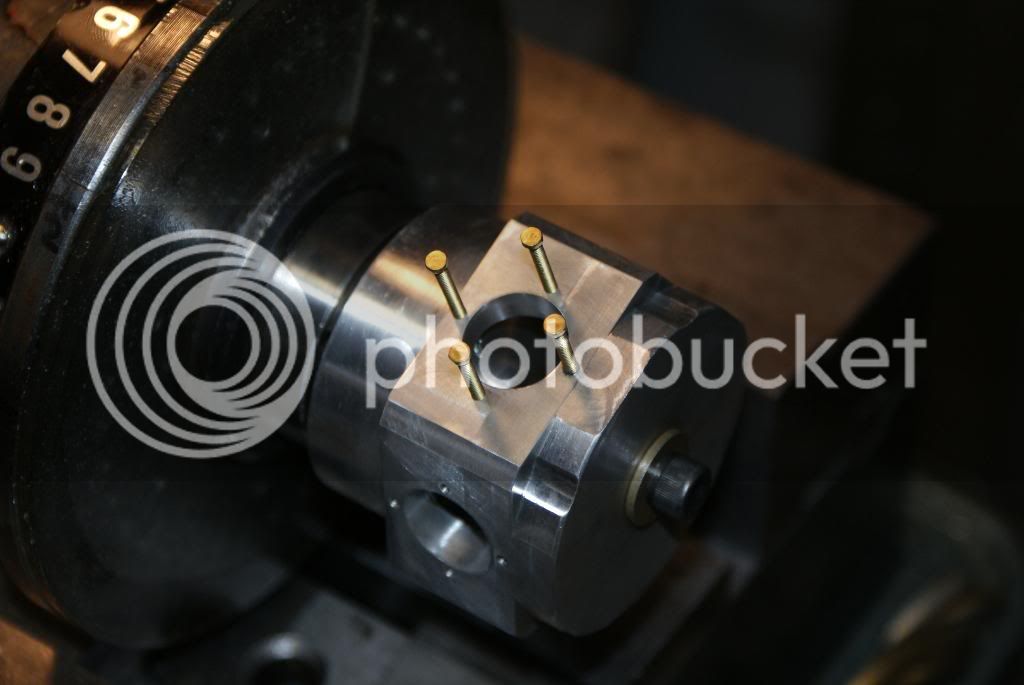

I am making 2 more radial 5 engines as gifts for 2 very good friends. I will post pictures as the build goes on. I have started on the cylinders first got some work done but got a lot more to go about 2.5 hours in the 12 cylinders so far. I will post pictures later today. I got to get back to clearing the 16 inches of snow that fell yesterday