I got back from Nepal a week ago, but a combination of jetlag and a chest cold have kept me out of the shop until this weekend. Today's goal was to rough out the two lifting links, pieces that connect the lift arms to the expansion links. These are somewhat "delicate" as ET says, so it took me some thought as to how to make them.

Material is 1/4" diameter drill rod. First a length is chucked in the lathe collet, and i faced the end and center drilled it.

The rod and collet were then transferred to a square collet block and secured in the mill vise. A vise stop was used to ensure repeatability. A 1/4" carbide endmill then milled a flat .055" deep 1/8" from the end of the rod. Leaving the spindle locked, I turned the block over, positioned against the vise stop, and milled a matching flat on the opposite side of the rod. Next a 1/8" hole is drilled through the rod.centered on the flat.

Next the collet block is moved to the surface plate, and the drill rod is pulled out ~ 2". The height gauge is used to set the milled flat parallel to the plate.

Back to the mill vise. I used the 1/8" drill bit in the existing hole to zero the DRO, then moved the X-axis 1.625" to establish the location of the flat/hole on the other end.

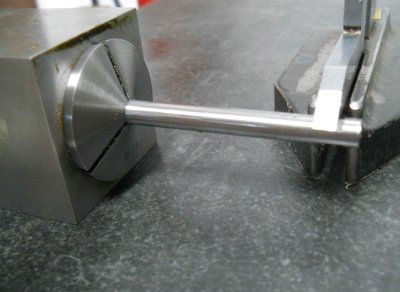

The collet and rod are then placed back on the lathe to turn down the shaft between the flats. The non-chucked end is supported by a live center. First I used a parting tool to turn down the right end of the shaft to provide space for a turning tool.

Then the rest of the shaft was turned.

After some polishing of the shaft with emery cloth and scotchbrite, I parted off the link. After the first one, it took only about 15 minutes to make the second.

In my next shop session I will grind off the center-drilled portion and do some cleanup filing on the ends.