You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building Jerry's Donkey

- Thread starter Captain Jerry

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Dec 2, 2008

- Messages

- 971

- Reaction score

- 8

Sam, Zee, Dean , Dave, Bob, and Ron

Thanks for the kind words and the encouragement. The work continues and slowing down is well within my abilities. I have come to realize that this may be a lifelong project and as such, it is not necessary to hurry. The unforseen challenges pop up and eventually a solution comes along.

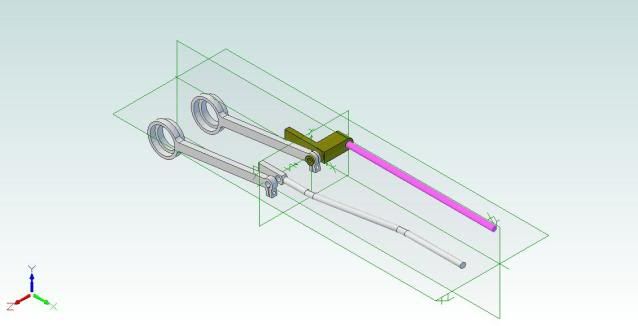

This is my current challenges. The valve rods are bent. I mean they are supposed to be.

The valve bore is not in line with the guide at the outer end. The rod has a flat section at the outer end that fits into a guide on the hoist A-frame with the eccentric strap joined to it just aft of the guide. The offset is just about 1/4". I am waiting for some idea to pop up that will let me make that rod bend and keep everything parallel. It looks like this could be a real bind point.

I would like to follow the original but I am thinking about making a brass angle plate at the outer end to handle the jog. Alternatively, I could put the guide on the inside of the A-frame which would leave the rod straight. I would have to put an offset on the end of the eccentric strap to reach over to the attachment point on the valve rod. No decision yet. Any opinions or alternative ideas?

Jerry

Thanks for the kind words and the encouragement. The work continues and slowing down is well within my abilities. I have come to realize that this may be a lifelong project and as such, it is not necessary to hurry. The unforseen challenges pop up and eventually a solution comes along.

This is my current challenges. The valve rods are bent. I mean they are supposed to be.

The valve bore is not in line with the guide at the outer end. The rod has a flat section at the outer end that fits into a guide on the hoist A-frame with the eccentric strap joined to it just aft of the guide. The offset is just about 1/4". I am waiting for some idea to pop up that will let me make that rod bend and keep everything parallel. It looks like this could be a real bind point.

I would like to follow the original but I am thinking about making a brass angle plate at the outer end to handle the jog. Alternatively, I could put the guide on the inside of the A-frame which would leave the rod straight. I would have to put an offset on the end of the eccentric strap to reach over to the attachment point on the valve rod. No decision yet. Any opinions or alternative ideas?

Jerry

I would suggest a bending fixture with the correct offset built into it.

Post a drawing, and we can take a look.........

Don't worry Jerry...It can be fun when you don't know what to do next....roll with it.... ;D

Dave

Post a drawing, and we can take a look.........

Don't worry Jerry...It can be fun when you don't know what to do next....roll with it.... ;D

Dave

- Joined

- Dec 2, 2008

- Messages

- 971

- Reaction score

- 8

Dave

Here is another view of the rod.

The offset is more obvious here. That is only part of the problem. The flat section at the end is also a problem. The original was probably forged iron. Even if I could hammer a flat on the end of my 5/32" stainless valve rod, there is not enough material to maintain the dimensions. I'll try to post some drawings this evening but for now, I'm off to the shop.

Jerry

Here is another view of the rod.

The offset is more obvious here. That is only part of the problem. The flat section at the end is also a problem. The original was probably forged iron. Even if I could hammer a flat on the end of my 5/32" stainless valve rod, there is not enough material to maintain the dimensions. I'll try to post some drawings this evening but for now, I'm off to the shop.

Jerry

Hi Jerry,

It looks a bit daunting...but I don't think it is really.

Take a piece of stock the same diameter as a practice piece and put the "valve" end + twice the valve travel in a mill vice and bend the other end by hand to the offset required.......

At least you'll know if you need to get more sophisticated....

Dave

It looks a bit daunting...but I don't think it is really.

Take a piece of stock the same diameter as a practice piece and put the "valve" end + twice the valve travel in a mill vice and bend the other end by hand to the offset required.......

At least you'll know if you need to get more sophisticated....

Dave

Hi Jerry

Still following along with great interest. for the current bit: perhaps only one bend in some round stock, and solder the other end at the required angle to a correctly sized bit of flat stock for the flat guide?

Cheers, Joe

Still following along with great interest. for the current bit: perhaps only one bend in some round stock, and solder the other end at the required angle to a correctly sized bit of flat stock for the flat guide?

Cheers, Joe

- Joined

- Dec 2, 2008

- Messages

- 971

- Reaction score

- 8

Dave and Joe

Thanks for your interest and suggestions. I will try bending the rod and soldering a flat giude piece on the end but I don't have much faith in it success. There is not a lot of material contact area. Attached is a drawing that I am thinking about. The rod will be threaded and screwed into the bracket. The eccentric strap will be seated on the boss and fastened with either screw or stud.

Jerry

Thanks for your interest and suggestions. I will try bending the rod and soldering a flat giude piece on the end but I don't have much faith in it success. There is not a lot of material contact area. Attached is a drawing that I am thinking about. The rod will be threaded and screwed into the bracket. The eccentric strap will be seated on the boss and fastened with either screw or stud.

Jerry

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Jerry,

Sorry to be a party pooper....but.....I don't think that's the way to go.

My feeling is there will be to much load on the pin hole in the end of the flat bar and too much flex in the eccentric rod and adapter arm, the result being the eccentric rod and the end of the arm describe an ellipse which would play havoc with the valve timing.

However, I've been wrong before. Maybe it's worthy of consideration. ???

Maybe it's worthy of consideration. ???

Best Regards

Bob

Sorry to be a party pooper....but.....I don't think that's the way to go.

My feeling is there will be to much load on the pin hole in the end of the flat bar and too much flex in the eccentric rod and adapter arm, the result being the eccentric rod and the end of the arm describe an ellipse which would play havoc with the valve timing.

However, I've been wrong before.

Best Regards

Bob

- Joined

- Dec 2, 2008

- Messages

- 971

- Reaction score

- 8

Bob

Thanks for taking a look and for your poop. ;D

I had thought that there would not be much torque involved. The flat part of the bracket is captured in a guide which should eliminate any side thrust and torque. The purpose of the bracket is just to eliminate any misalignment caused by imprecise bending. Just to be sure we are looking at this from the same viewpoint, here is another drawing with the parts labeled.

Dave thinks that bending the rod will be easier than I think. If I bend the rod, I still have to get a flat piece on the end of it and attach the eccentric strap. I may just be over-thinking (or under-thinking) the problem, or non-problem.

Jerry

Thanks for taking a look and for your poop. ;D

I had thought that there would not be much torque involved. The flat part of the bracket is captured in a guide which should eliminate any side thrust and torque. The purpose of the bracket is just to eliminate any misalignment caused by imprecise bending. Just to be sure we are looking at this from the same viewpoint, here is another drawing with the parts labeled.

Dave thinks that bending the rod will be easier than I think. If I bend the rod, I still have to get a flat piece on the end of it and attach the eccentric strap. I may just be over-thinking (or under-thinking) the problem, or non-problem.

Jerry

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Captain Jerry said:Bob

Dave thinks that bending the rod will be easier than I think. If I bend the rod, I still have to get a flat piece on the end of it and attach the eccentric strap. I may just be over-thinking (or under-thinking) the problem, or non-problem.

Having bent one and having had the "nervous nellies" before I did it. ;D

I can assure you that Dave is correct, (at least in my case).

I've had a look at your drawing and I understand a bit better, (I think). That being the case where I used the term valve rod before I meant what you have termed the eccentric strap and the hole and the transition arm.

Best Regards

Bob

Hi Jerry,

If I were you.....I would take a piece of coat hanger wire and try it out..do it a couple of different ways...experiment....prove me right or wrong, beat me up call me bad names.... I don't care, but you will then have the information you seek and you will know...

Just have fun trying.... ;D

Dave

If I were you.....I would take a piece of coat hanger wire and try it out..do it a couple of different ways...experiment....prove me right or wrong, beat me up call me bad names.... I don't care, but you will then have the information you seek and you will know...

Just have fun trying.... ;D

Dave

- Joined

- Dec 2, 2008

- Messages

- 971

- Reaction score

- 8

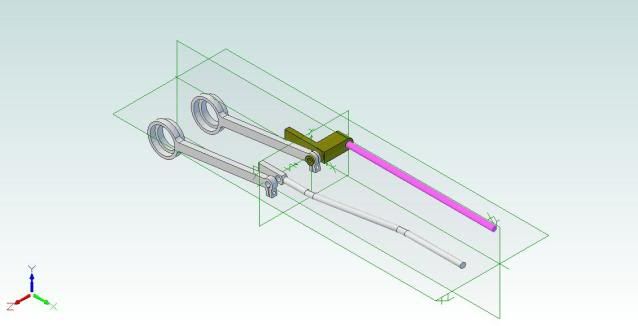

Still messing around with valve rod and guide design although not seriously. My wife and I are traveling and visiting friends and family and I won't really be in the shop again until end of next week but that doesn't keep me from noodling about the problem. I may have made too much of the bend when the real problem is the transition from round to rectangular cross section at the guide end and the attachment at that point to the eccentric rod.

The purpose of the rectangular section is to prevent twist of the valve rod due to the bend and to prevent up/down deflection caused by the eccentric rod. Previous drawings that I have shown have not been very clear on that so here is another one.

This was a quickie drawing and the rectangular section of the guide is out of scale between the two versions. Also missing is the bushing that guides this end of the rod. Just use your imagination and know that the valve rod is constrained to a horizontal plane with only reciprocal movement allowed by the guide bushing.

On the left is the configuration with the bent rod. If I were a talented welder I might attempt to build up the end of the rod (stainless) and grind it back to a rectangular section. I am not a welder and won't be one anytime soon.

On the right is the design I am leaning towards. It uses a straight rod threaded into a brass transition piece. The threaded part will make valve adjustment easier. The transition piece provides the lateral shift so the rectangular guide section is in line with the outer face of the A-frame where the guide bushing will be and it provides more meat to hold a pivot pin for the eccentric.

Thanks for your input, Dave and Bob. This may not be the final solution but it where I'm headed next week.

Jerry

The purpose of the rectangular section is to prevent twist of the valve rod due to the bend and to prevent up/down deflection caused by the eccentric rod. Previous drawings that I have shown have not been very clear on that so here is another one.

This was a quickie drawing and the rectangular section of the guide is out of scale between the two versions. Also missing is the bushing that guides this end of the rod. Just use your imagination and know that the valve rod is constrained to a horizontal plane with only reciprocal movement allowed by the guide bushing.

On the left is the configuration with the bent rod. If I were a talented welder I might attempt to build up the end of the rod (stainless) and grind it back to a rectangular section. I am not a welder and won't be one anytime soon.

On the right is the design I am leaning towards. It uses a straight rod threaded into a brass transition piece. The threaded part will make valve adjustment easier. The transition piece provides the lateral shift so the rectangular guide section is in line with the outer face of the A-frame where the guide bushing will be and it provides more meat to hold a pivot pin for the eccentric.

Thanks for your input, Dave and Bob. This may not be the final solution but it where I'm headed next week.

Jerry

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Jerry,

I would build it as shown in the photo.

Make a piece of flat with a boss to take the valve rod either screwed, silver soldered or welded into it. Then, dare I say it, BENT, to alignment.

Reason - you have done such a great job of replicating and scaling the engine and your straight rod seems somehow not right. As my Grandfather would say, "Listen lad, don't spoil the job for a halfpenny of tar." :bow:

Remember free advise is sometimes worth exactly what you pay for it. :

Best Regards

Bob

I would build it as shown in the photo.

Make a piece of flat with a boss to take the valve rod either screwed, silver soldered or welded into it. Then, dare I say it, BENT, to alignment.

Reason - you have done such a great job of replicating and scaling the engine and your straight rod seems somehow not right. As my Grandfather would say, "Listen lad, don't spoil the job for a halfpenny of tar." :bow:

Remember free advise is sometimes worth exactly what you pay for it. :

Best Regards

Bob

Maryak said:Jerry,

I would build it as shown in the photo.

Make a piece of flat with a boss to take the valve rod either screwed, silver soldered or welded into it. Then, dare I say it, BENT, to alignment.

Reason - you have done such a great job of replicating and scaling the engine and your straight rod seems somehow not right. As my Grandfather would say, "Listen lad, don't spoil the job for a halfpenny of tar." :bow:

Remember free advise is sometimes worth exactly what you pay for it. :

Best Regards

Bob

..................ditto...

Dave

- Joined

- Jan 3, 2008

- Messages

- 2,085

- Reaction score

- 17

Jerry, I hadn't checked in for a while but the whole project it looking great. I tend to agree with the silver soldering approach on the flat end of the valve rod. Enjoy your travels. Coming back to it in a week or so sometimes helps too with a fresh perspective.

Bill

Bill

Jerry---I am enjoying this thread immensly. You are doing a great job.---brian

- Joined

- Dec 2, 2008

- Messages

- 971

- Reaction score

- 8

OK, OK, OK! I get it! The purpose of this forum is to share ideas and experience and to keep people from doing dumb or dangerous stuff. Sometimes you have to stick to your guns and make your point instead of just saying "that's nice" and letting it go. Thanks, Bob and Dave, for sticking to your guns. You are right. I wasn't commissioned to redesign this engine. I will find a way to do it that respects the original design.

Bill, Brian, and Bob. Thanks for dropping in and leaving a note so I know you were there. Your kind comments are much appreciated.

Jerry

Bill, Brian, and Bob. Thanks for dropping in and leaving a note so I know you were there. Your kind comments are much appreciated.

Jerry

Similar threads

- Replies

- 76

- Views

- 13K

- Replies

- 14

- Views

- 950

- Replies

- 148

- Views

- 20K