Hi Y'all

OK, I have decided to remake the split bearings.

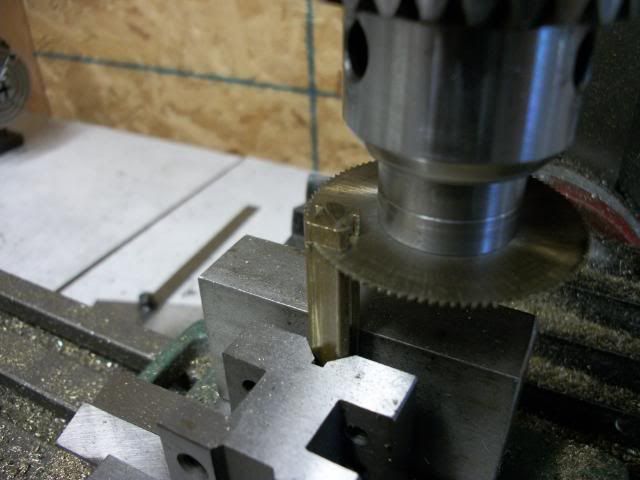

Step 1. Mill grooves in sides of brass bar to match bearing strap:

Step 2. Saw of to length ( 1/2 of finished bearing) 8 pieces:

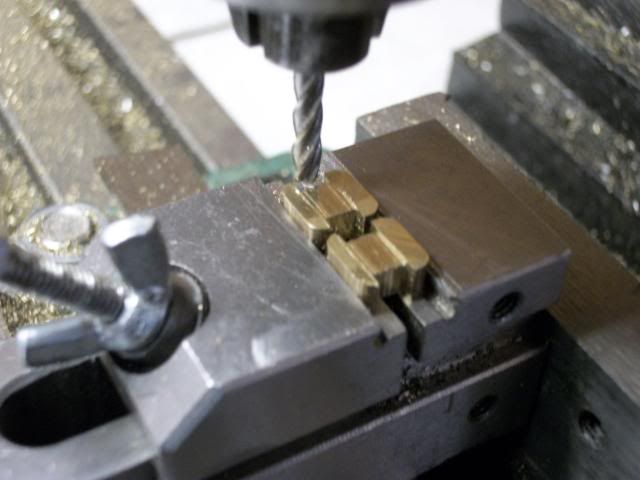

Step 3. Mill slots on 3rd side of bearing halves so that a pair will have groove on all four edges.

Step 4. Test fit pairs to bearing strap:

Step 5. Test fit to con rod.

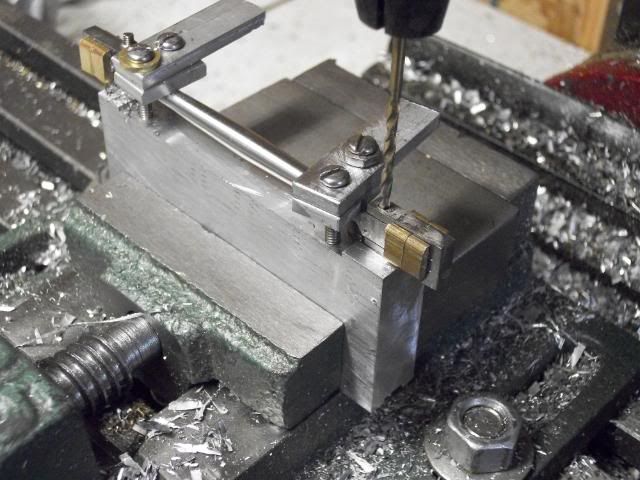

Step 6 Drill for clamp bolts. The fishbellied rod needed a holding fixture to clear the belly.

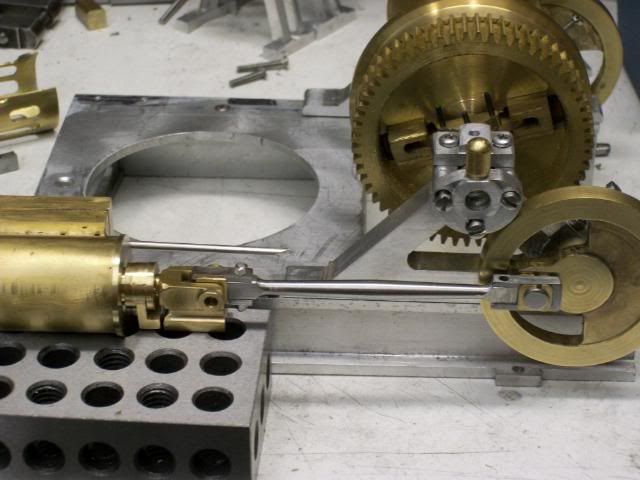

Step 7. Mill bearing faces to finished dimension. The faces sit proud of the con rod face by .020"

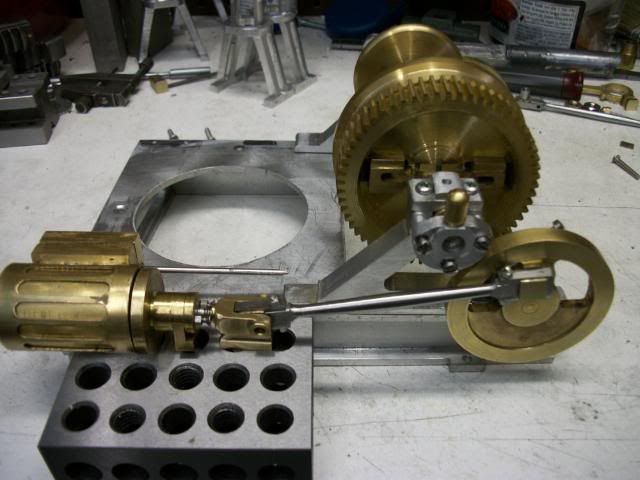

Step 8. Test fit to Xhead guide and orient to assembly.

Oh! crap!!!

The assembly is 1/2" too long. I thought I had more room in there and got a little careless with the packing gland and crosshead support bracket design. I may be able to get some space if I shorten the Xhead a bit but not much. I could cheat the location of the cylinders a bit but not much. I will either have to get it back in a remake of the head, packing gland, support bracket or the frame. I'm Not! remaking the rods!

Jerry

PS. The sea trial went well. Beautifull day, steady winds, great conditions and the buyer was drooling. The surveyor was satisfied with all systems which worked to perfection. Back to the boatyard to haul out for bottom inspection. YIKES! HORROR! The rudder is broken. A huge crack, leading edge to trailing edge, in the middle of the rudder, open all the way to the core. It was not there the last time I was under the boat in the crystal clear waters of The Bahamas. Obvious impact damage but damned if I know when. Coastal and inland waters of the US are so murky that divers who clean the bottom do it mostly by feel and none had reported the damage.

The buyer is still happy and the deal is almost done but I have to provide him with a new rudder. I'll be busy with that for the next few weeks so further progress will be intermittent.