- Joined

- Dec 2, 2008

- Messages

- 971

- Reaction score

- 8

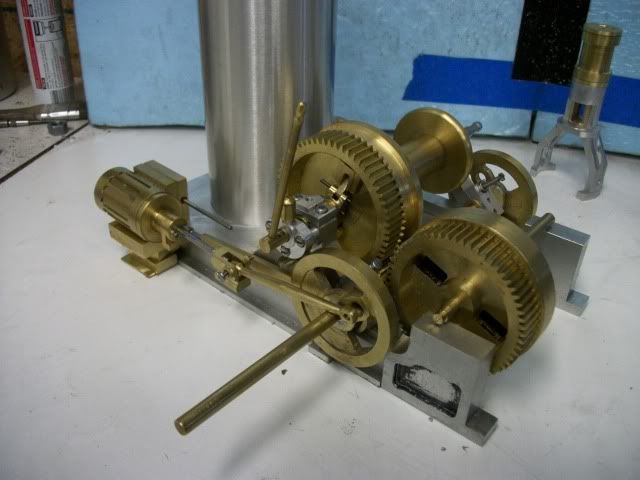

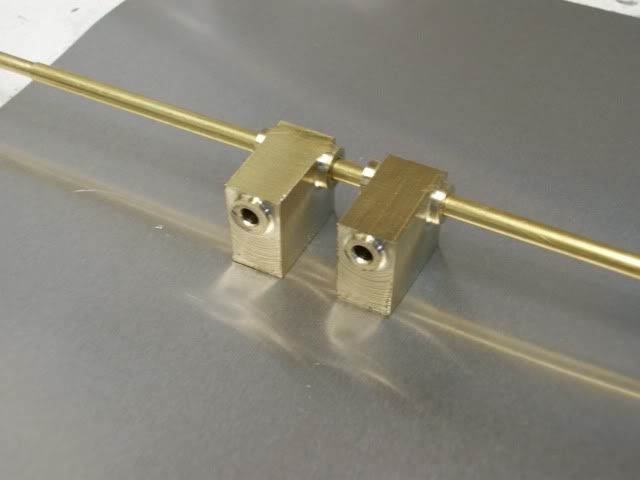

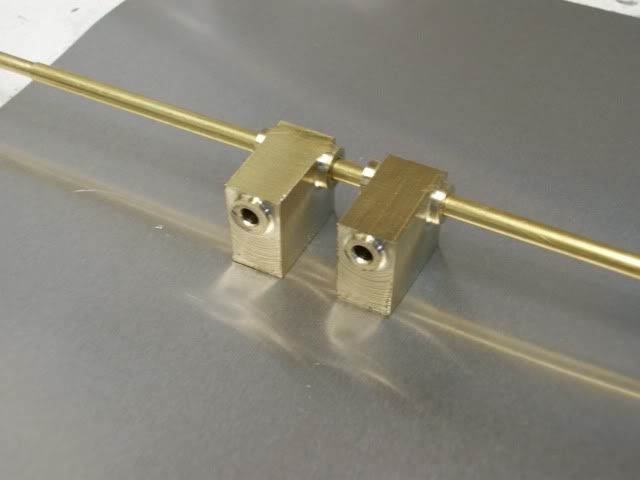

I made the crosshead guides today.

When I started this project, I considered all of the big pieces. If I had looked at all of the little pieces, I might have started on something else. The small parts aren't any harder, just harder. This is the cross head.

Here are some pics of the successful (mostly) processes. My camera doesn't seem to get pictures of the disasters. I have a lot to learn and mistakes are one way to do that.

I started by sawing some chunks of brass to size:

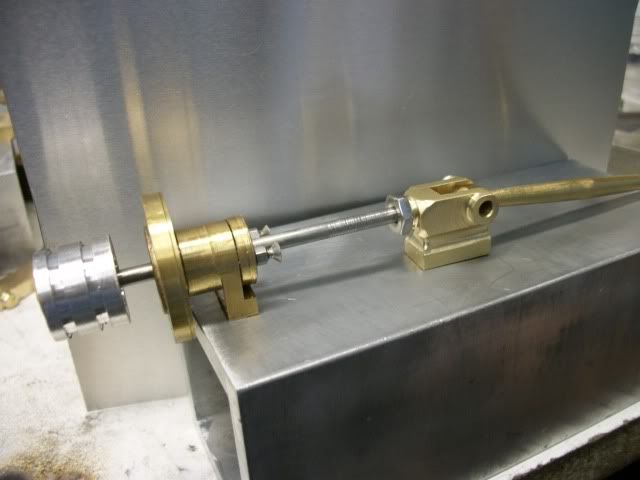

Drilled crosswise for the con rod pin and lengthwise for the piston rod:

Once again, I'm using the tailstock ram and the live center to mash the part against a piece of oak against the 3-jaw chuck. I know, I look like a one trick pony, but its a good trick and it gets around my limited equipment. I don't have a 4-jaw for the lathe and this gives me a way to center the bore when it is not centered on the part.

part on lathe

I modified the setup by adding a centering pin to maintain alignment. The part is longer than it is thick. Its not like a disk or a flat plate so this is important:

The bosses turned:

The piston rod boss was turned first and then one of the side bosses. When the part is reversed for the second side boss the first side boss sinks into the oak. Here is the pair complete with bosses:

The slot for the connecting rod is milled:

After a little profiling with an end mill and a little hand filling:

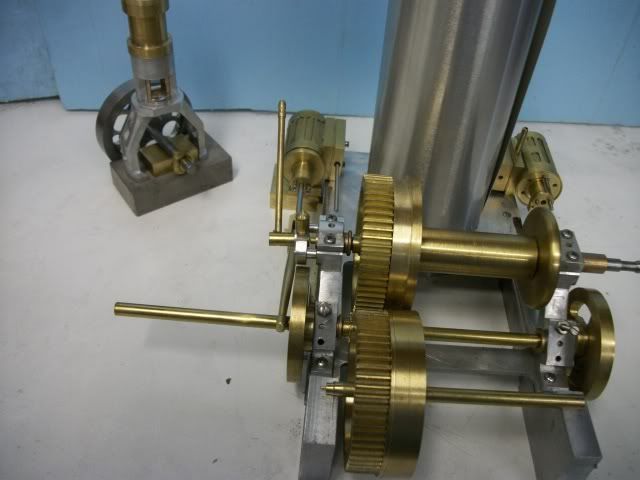

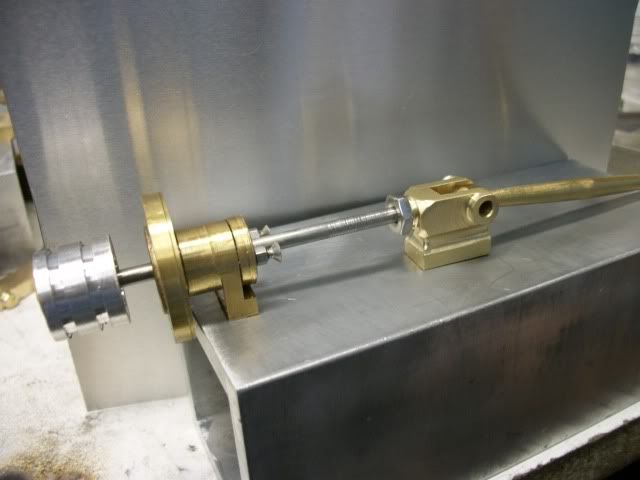

Trial assembly:

Thats it for the progress. Now a question for the experienced engineers. Referring to the first pic in this post, you will see two slots cut across the cross head guide between the crosshead and the piston. There is a similar slot across the guide at the far end of the stroke. These slots are probably to prevent a wear ridge from forming at the end of the stroke. But why two slots at the piston end? There is only one slot at the other end. Also not little evidence of wear on the bar. Based on obvious wear at other points, I would have expected to see more wear here.

Jerry

PS

When I started this post, I put some eggs on to boil for potato salad for the holiday weekend. Note: It took longer to write this post than it did for the pot to boil dry and for the eggs to explode!

When I started this project, I considered all of the big pieces. If I had looked at all of the little pieces, I might have started on something else. The small parts aren't any harder, just harder. This is the cross head.

Here are some pics of the successful (mostly) processes. My camera doesn't seem to get pictures of the disasters. I have a lot to learn and mistakes are one way to do that.

I started by sawing some chunks of brass to size:

Drilled crosswise for the con rod pin and lengthwise for the piston rod:

Once again, I'm using the tailstock ram and the live center to mash the part against a piece of oak against the 3-jaw chuck. I know, I look like a one trick pony, but its a good trick and it gets around my limited equipment. I don't have a 4-jaw for the lathe and this gives me a way to center the bore when it is not centered on the part.

part on lathe

I modified the setup by adding a centering pin to maintain alignment. The part is longer than it is thick. Its not like a disk or a flat plate so this is important:

The bosses turned:

The piston rod boss was turned first and then one of the side bosses. When the part is reversed for the second side boss the first side boss sinks into the oak. Here is the pair complete with bosses:

The slot for the connecting rod is milled:

After a little profiling with an end mill and a little hand filling:

Trial assembly:

Thats it for the progress. Now a question for the experienced engineers. Referring to the first pic in this post, you will see two slots cut across the cross head guide between the crosshead and the piston. There is a similar slot across the guide at the far end of the stroke. These slots are probably to prevent a wear ridge from forming at the end of the stroke. But why two slots at the piston end? There is only one slot at the other end. Also not little evidence of wear on the bar. Based on obvious wear at other points, I would have expected to see more wear here.

Jerry

PS

When I started this post, I put some eggs on to boil for potato salad for the holiday weekend. Note: It took longer to write this post than it did for the pot to boil dry and for the eggs to explode!