Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

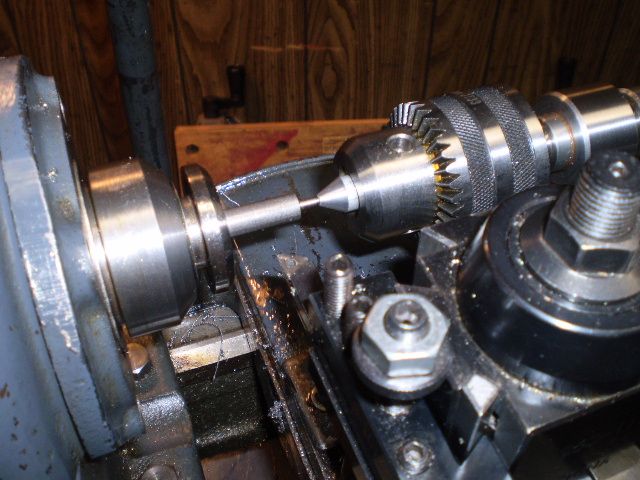

I started the cylinder and am working slowly since there seems to be a lots of places where I can ruin it. I decided to use the rotary table to drill the eight #8 mounting holes. In order to attach the work to the table, I turned the work to 3 diameters. The smallest is a 25 mm register that fits in the rotab. The middle diameter is a register of 30 mm that fits in the cylinder and the largest diameter is the head itself. Finally, the small end was tapped 3/8 -16 so I could bolt the work to the table. Shown here with the holes drilled

I must admit drilling holes on a bolt circle is pretty easy once you figure out how to attach the work to the table.

Then, convincing myself that no further machining was required on the rotab I removed the head, parted off most of the small end and faced it to length. Then I checked it for fit on the cylinder.

Before I machine the cylinder head further I'm going to make a trial valve and cage assembly. Then I'll tap the head to hold them.

I'll be a while because I'm winging it with dimensions

Cheers,

Phil

I must admit drilling holes on a bolt circle is pretty easy once you figure out how to attach the work to the table.

Then, convincing myself that no further machining was required on the rotab I removed the head, parted off most of the small end and faced it to length. Then I checked it for fit on the cylinder.

Before I machine the cylinder head further I'm going to make a trial valve and cage assembly. Then I'll tap the head to hold them.

I'll be a while because I'm winging it with dimensions

Cheers,

Phil