Car parts stores or Amazon are the cheapest. Drill bit is one included in a full 1/64 step set which you probably have. These small kits usually have 5 inserts.Help!!! I buggered up a sparkplug thread. It should have been 1/4-32 but I pooched it. I have too much work in the cylinder head to scrap it, so I'm looking for a Helicoil kit that will let me save the head. Who can help me find a Helicoil kit that will get me out of trouble. I only need one Helicoil but the kits I've seen have 25 or 30 Helicoils in the kit. I need to buy the drill, the tap, and a driver (maybe). Can somebody line me up with a kit that has the least number of Helicoils in it. ----Brian

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

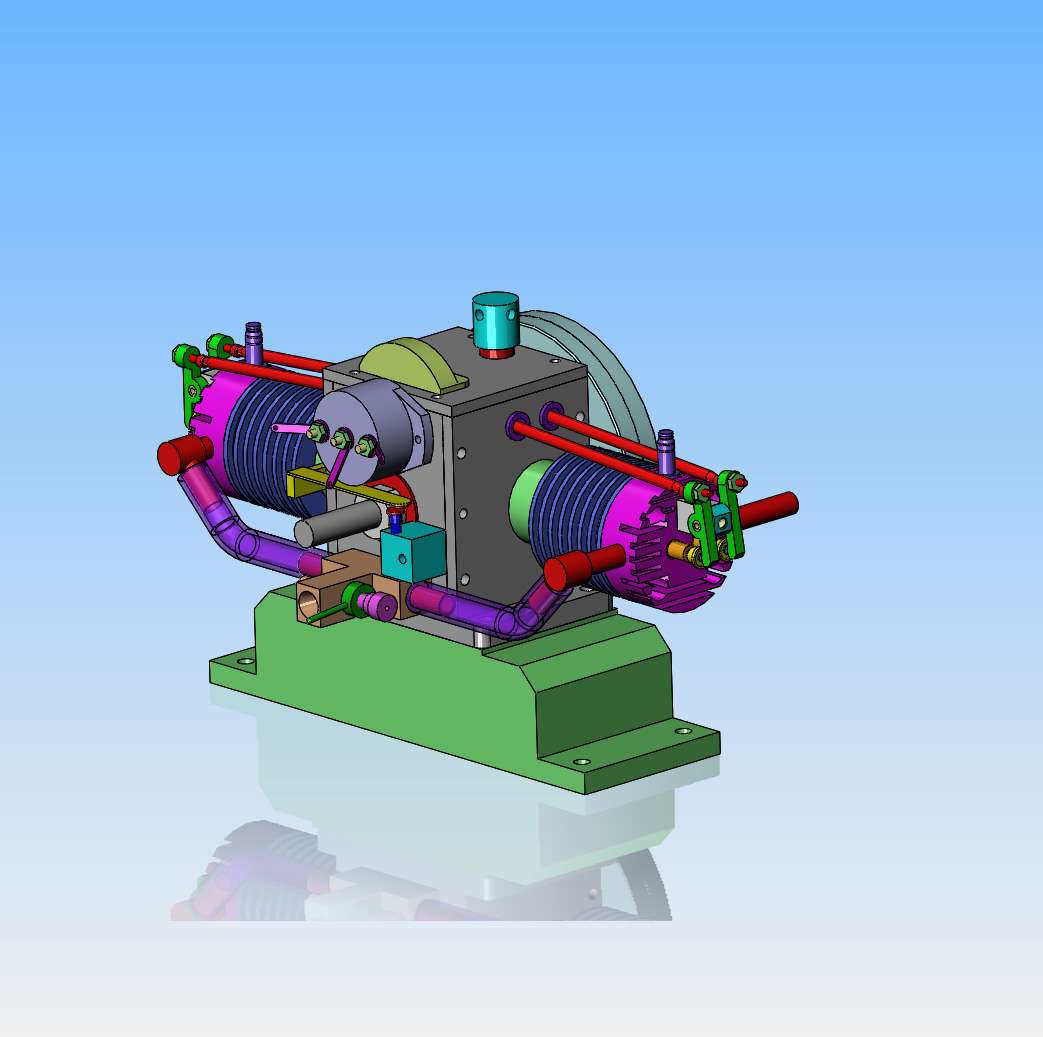

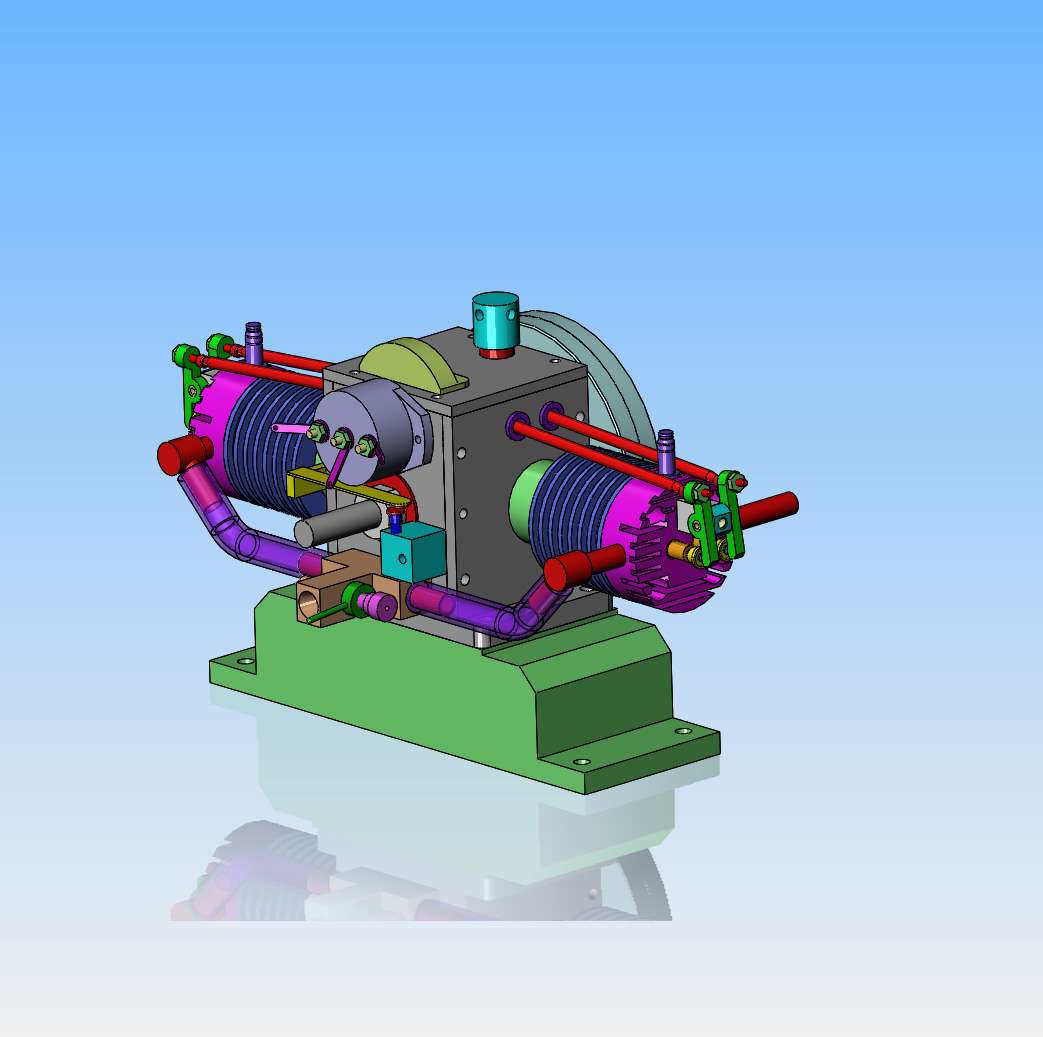

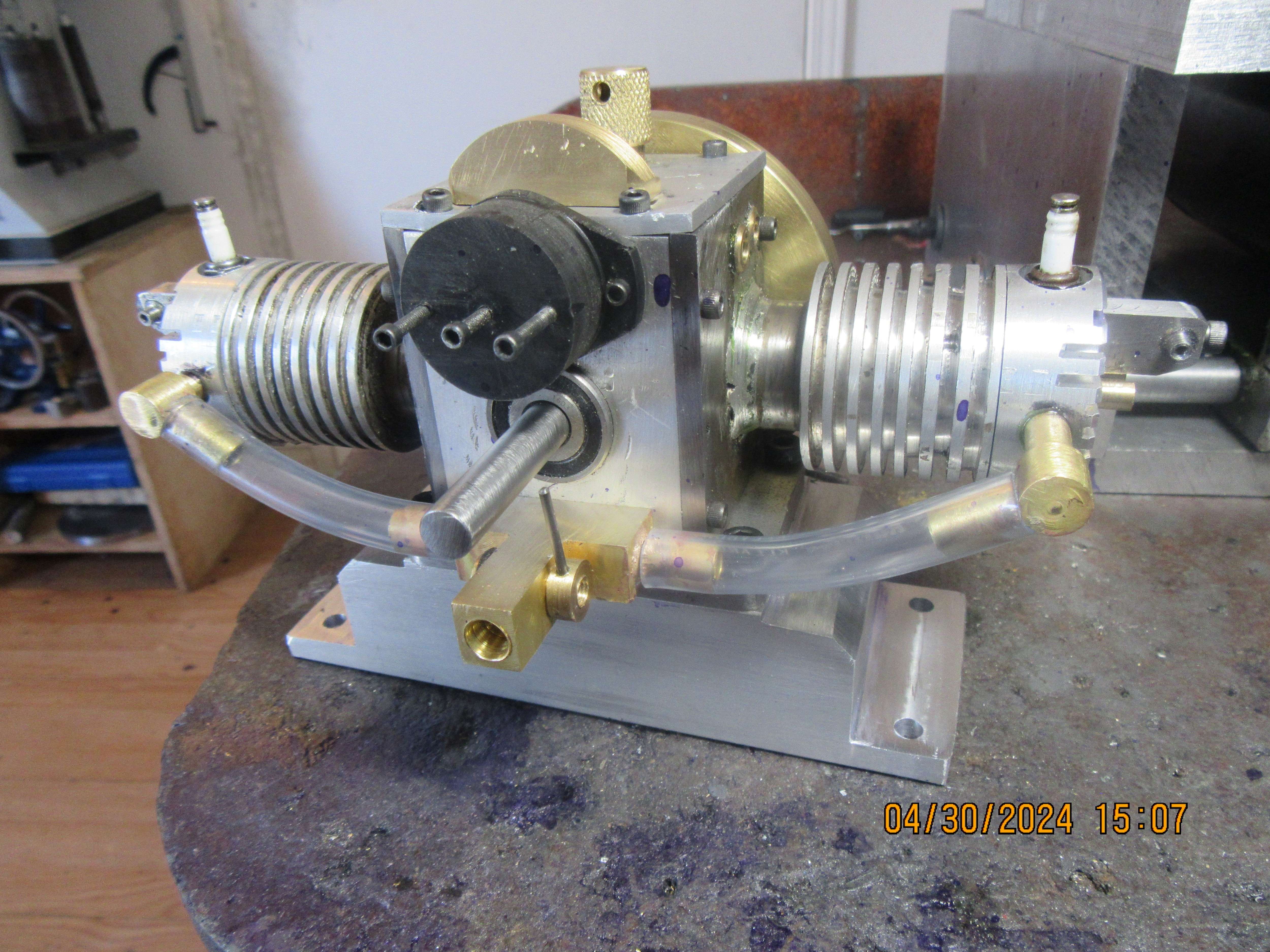

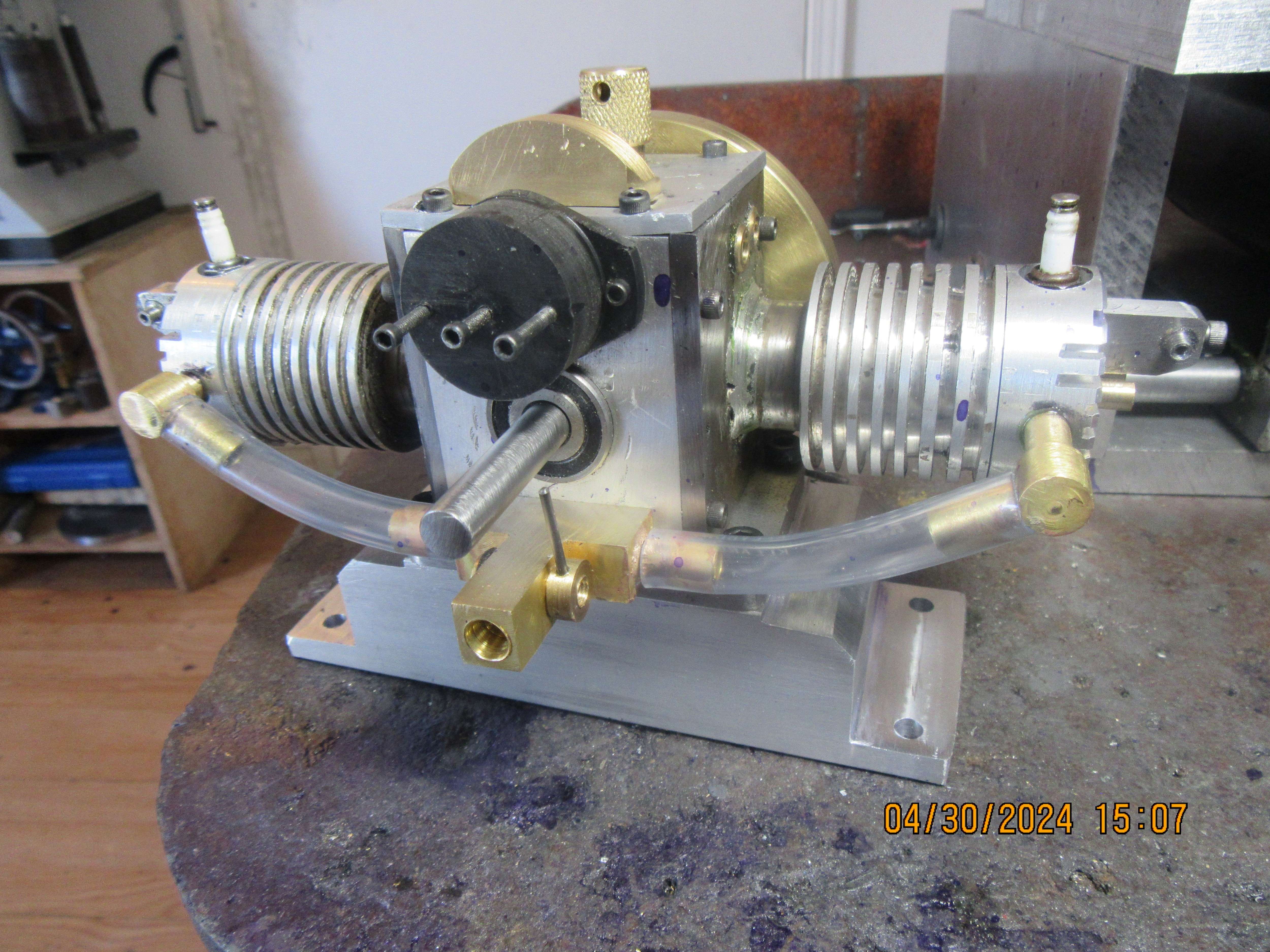

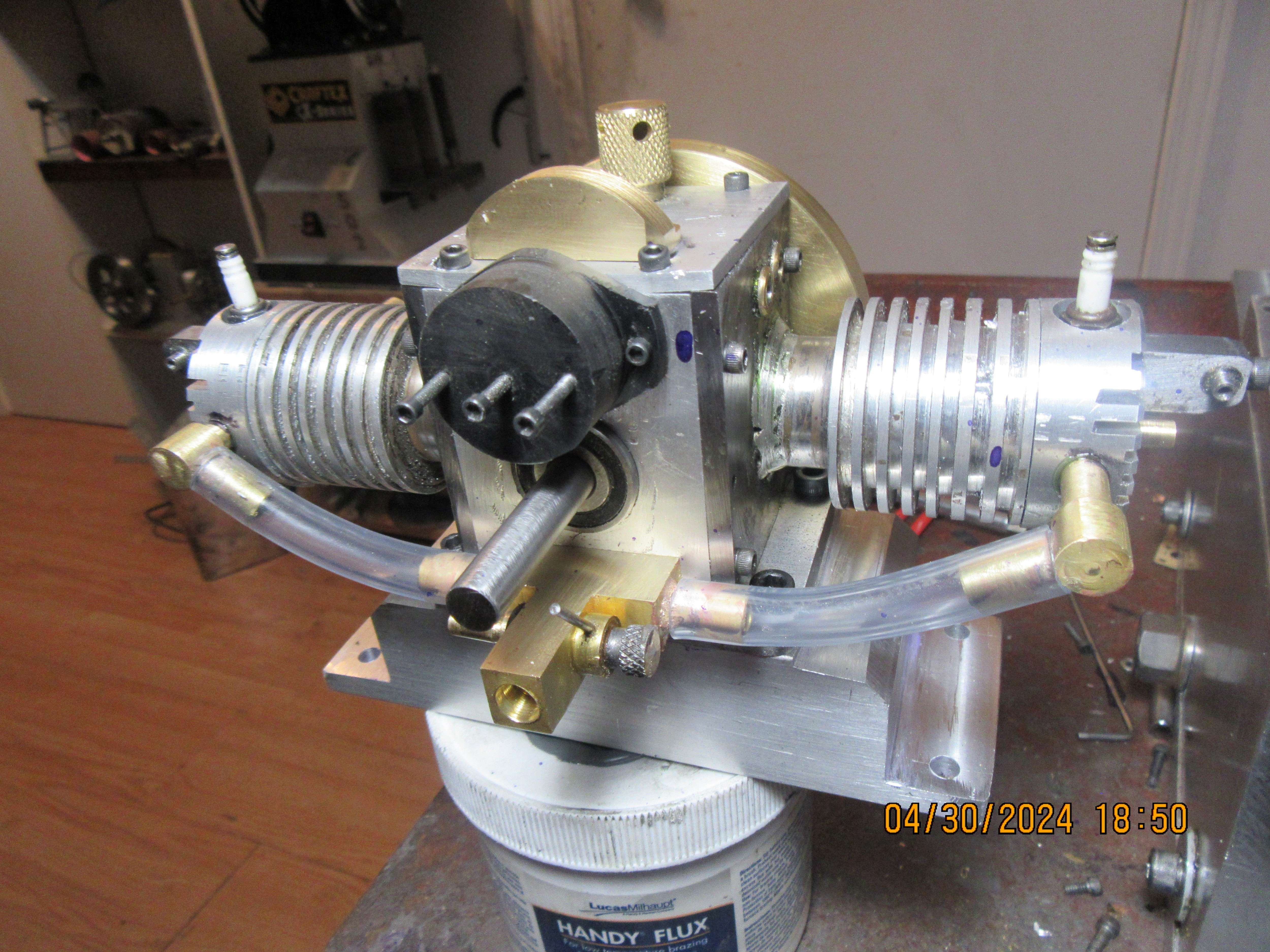

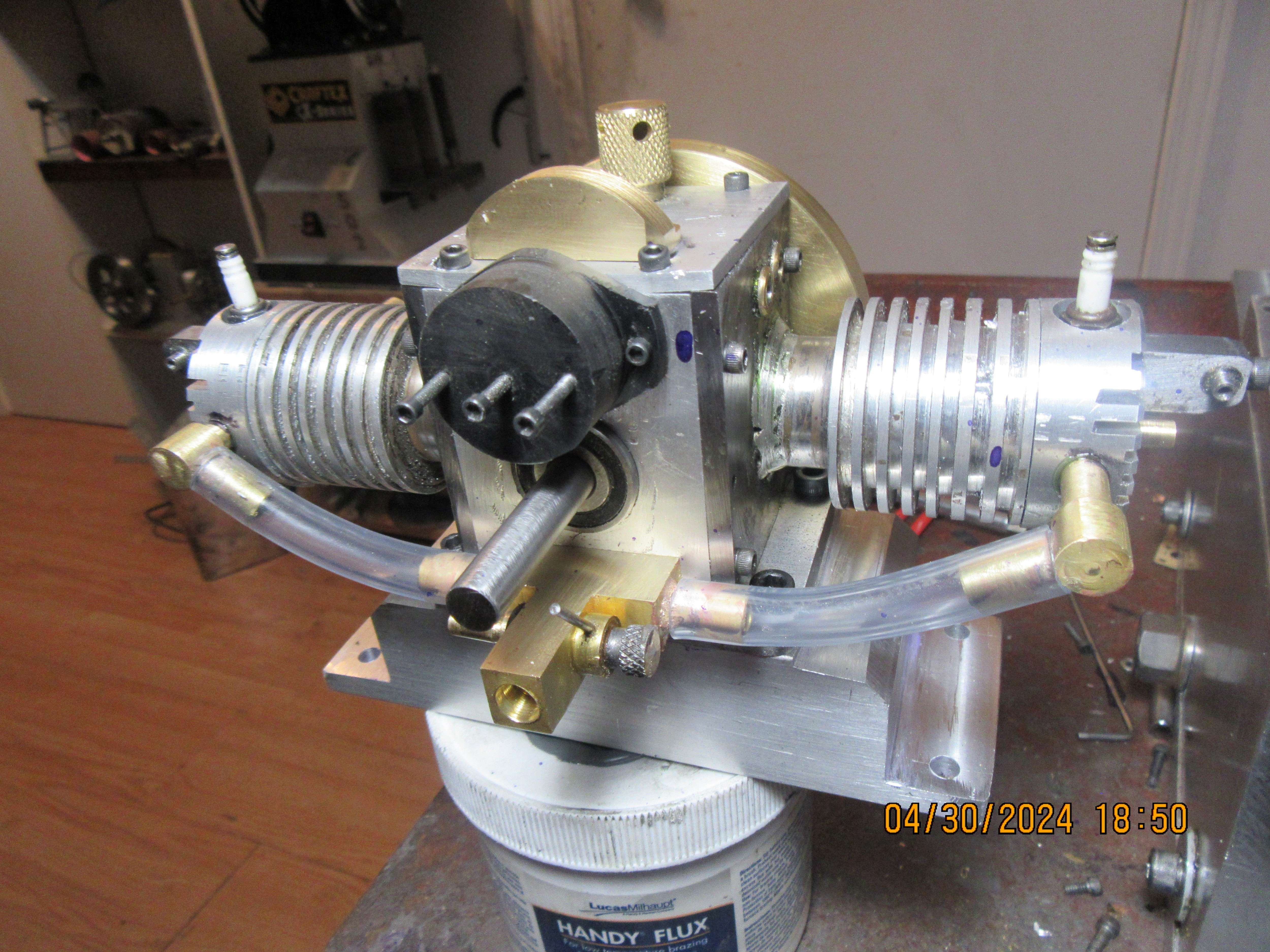

Upshur's opposed twin engine

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Chances are the small copper washer on a 1/4 x 32 plug won't have enough surface area to seal against if you put the larger helicoil in. Any other options to try and seal it will likely end in loss of compression.

May be better to tap it out to something a reasonable size 3/8 or 7/16 and make an aluminium insert to screw in with the aid of Loctite.

May be better to tap it out to something a reasonable size 3/8 or 7/16 and make an aluminium insert to screw in with the aid of Loctite.

- Joined

- Jan 4, 2011

- Messages

- 1,334

- Reaction score

- 344

1/4-32 is probably going to be a problem. That is not a common size. 1/4-20 and 1/4-28 but not 1/4-32

Brian,1/4-32 is probably going to be a problem. That is not a common size. 1/4-20 and 1/4-28 but not 1/4-32

I would suggest you drill and tap oversize and make your own threaded insert and loctite it in.

Then you could use steel material for the insert. I have made this repair on my projects lots of times.

You can also put a grub screw in the outer thread to secure it in place.

Good luck. I am following along.

Mike

MSC at least doesn't list any 1/4-32 thread repair inserts. I think the practical repair will be as JasonB suggested, use Loctite retaining compound to secure a shop made plug.1/4-32 is probably going to be a problem. That is not a common size. 1/4-20 and 1/4-28 but not 1/4-32

Oh, that rocker stud hole may be in the way.

Might actually be an advantage as you can redrill and tap it then the stud/screw will help stop the plug screwing out

Might actually be an advantage as you can redrill and tap it then the stud/screw will help stop the plug screwing out

Mike1

Mike1

When I built my Wyvern gas engine I had a similar problem, I did a similar repair as the one Jason suggested but instead of Loctite I used JB Weld smeared on the threads the repair was a success.

Mike.

Mike.

Brian, you have stripped 1/4 x 32 threads in other engines. Is it heavy handedness or are you using the wrong tapping drill and not getting a deep enough thread ? What plugs are you using, if something like a V3 they have very short thread length so more likely to strip than a standard length VR2 Either way be careful with the other head.

Also looking at Helicoil data for 1/4 x 32 you probably don't have the length for a helocoil.

Also looking at Helicoil data for 1/4 x 32 you probably don't have the length for a helocoil.

Last edited:

It was my own fault. I used the wrong size tap drill.

We have a carburation system!!! Very simple but ingenious carburetor. I'm happy with this. I still have a couple of carb parts to make, but they are not big jobs. Then, on to the rocker arms.

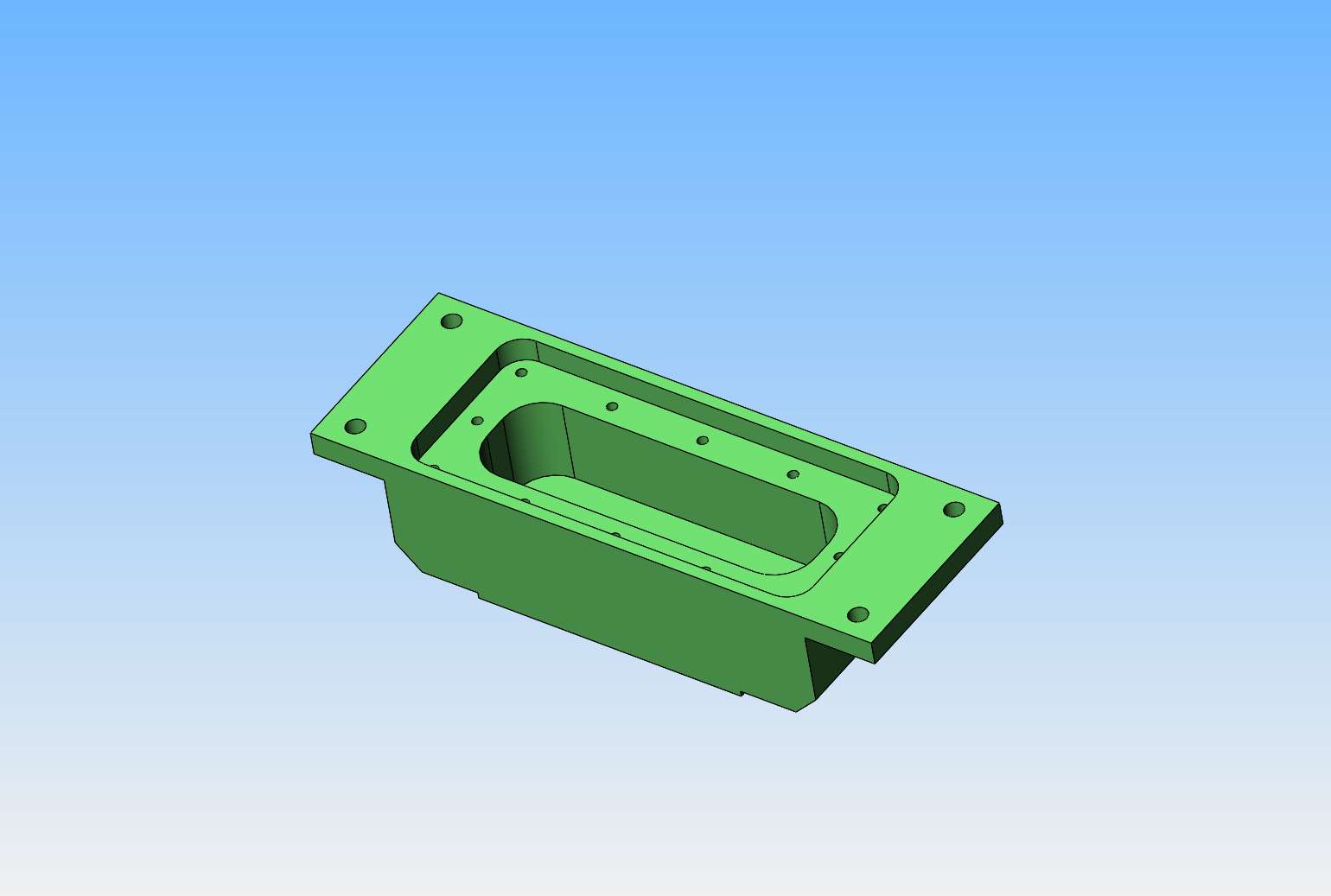

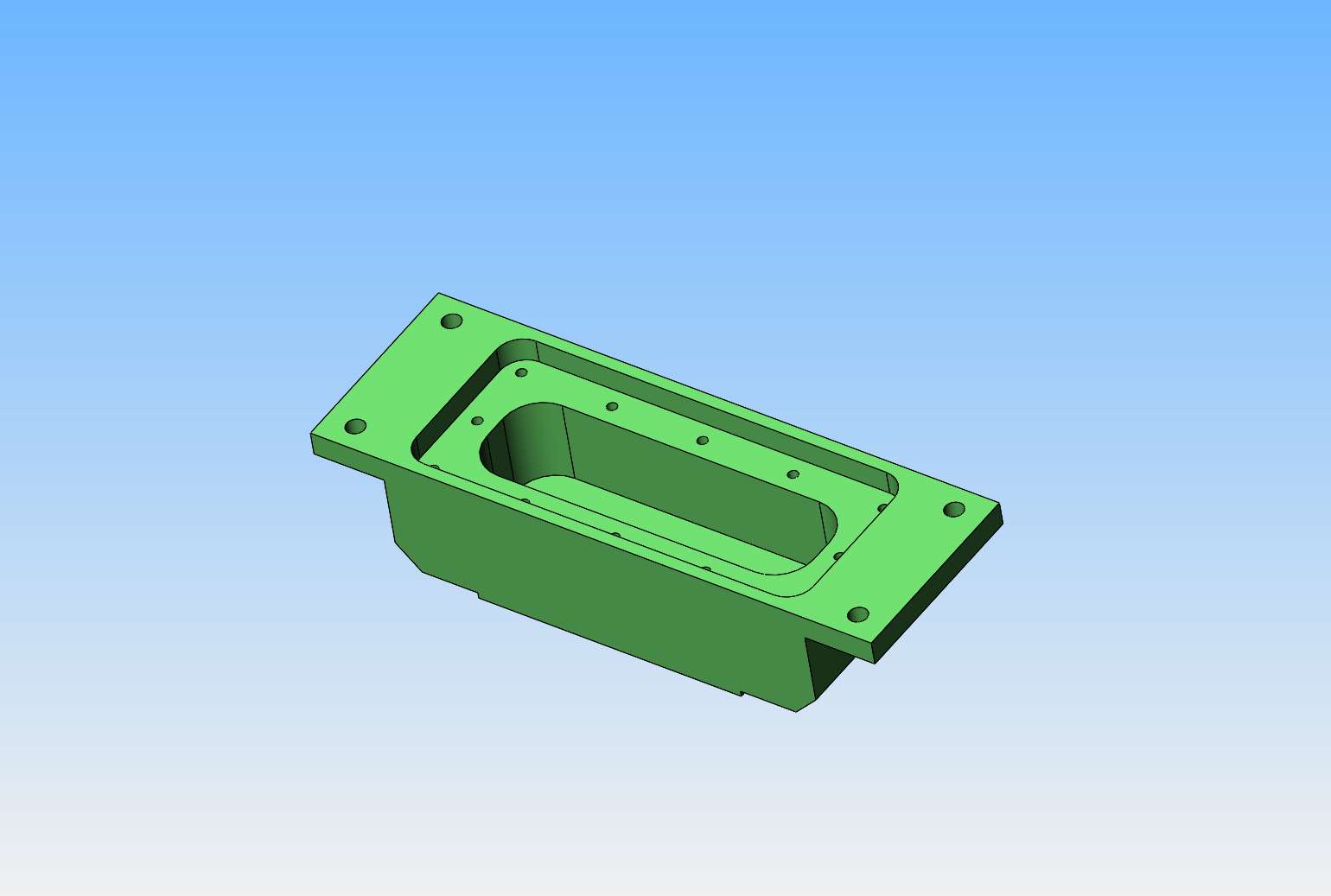

Since I need a gas tank, as well as a base for this engine, I think this is the way I will go. I happen to have a piece of 2" square aluminum that will provide my material. If I hollow it out from the underside and make a recessed bolt on cover plate with a gasket, it will be my gas tank as well.

Last edited:

Okay, that's a lot better with the sub base/gas tank mounted under the engine. Now I get to finish making carburetor bits. Something funky is going on with the DRO on my lathe, I hope it's something simple that I can fix.

Carburetor is finished. A couple of really small parts, well actually 3 machined parts and one rubber o-ring to hold the throttle assembly in place. This is probably one of the simplest carburetors that I have ever seen.

Good luck!!! My DRO wasn't buggered up, a cable connection had came loose. Big sigh of relief.--I've been thinking about making my own threaded insert to repair the damaged sparkplug threads on one cylinder head. It looks like I can make a piece 3/8" outside diameter with 3/8"-16 thread and a hole through the center with a 1/4"-32 thread, tap a 3/8" thread into the cylinder head and screw in the insert along with some J.B.Weld on the threads. I can make it from steel or from aluminum, which the head is made of. If I do that, it's not going to cost me any money. Since the head gets hot in operation, and the thermal expansion of steel is different from that of aluminum, probably aluminum would be best to make it from.

woodenbird

New Member

Very nice work, Brian. I have been following along as always and enjoying your latest build. Glad to hear you have decided on a fix for the sparkplug .

Glenn

Glenn

A finer thread for the plug would be better if you have suitable tap & die.

danallen

Well-Known Member

A die? Blasphemy! He has a lathe.A finer thread for the plug would be better if you have suitable tap & die.

But I don't think Brian likes screwcutting.

I did cut one thread on my lathe, just to prove that I could. My lathe is not a gear head, so it involved changing a few gears in the back of the lathe. Jason---Why would a fine thread be better?

Gives you a bit more solid cross section as the finer thread will have a larger core diameter.

Also as it is a blind thread you are unlikely to be able to tap to the end so as the taper on taps is usually proportional to the pitch you will get a full thread further into the hole if it is fine pitch

Also as it is a blind thread you are unlikely to be able to tap to the end so as the taper on taps is usually proportional to the pitch you will get a full thread further into the hole if it is fine pitch

Similar threads

- Replies

- 413

- Views

- 42K

- Replies

- 25

- Views

- 4K

- Replies

- 26

- Views

- 2K

- Replies

- 61

- Views

- 8K