Krown Kustoms

Well-Known Member

- Joined

- Aug 6, 2009

- Messages

- 313

- Reaction score

- 2

Thanks

that works out better

-B-

that works out better

-B-

Thanks--I fixed it.---BrianKrown Kustoms said:Brian, just to give you a heads up.

you have the dim for the spring at .2 on the drawing.

Its no big deal, everyone knows .2 is a bit big for spring wire, so natrually to adjust to .02

-B-

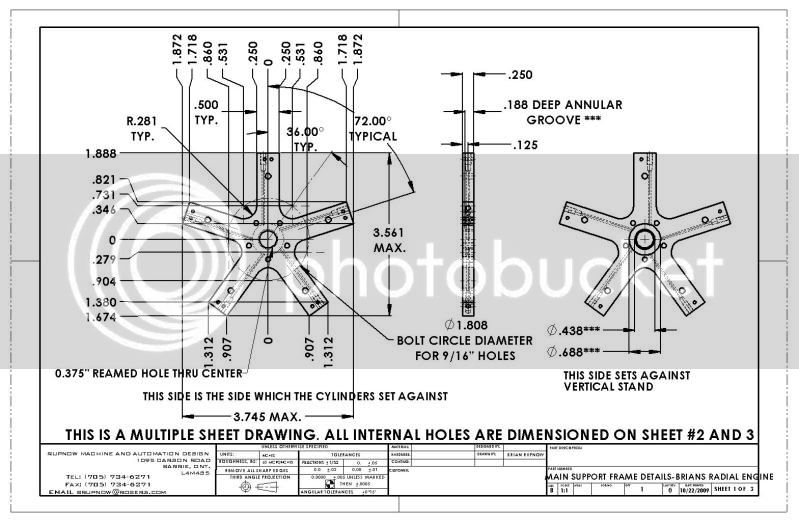

Krown Kustoms said:Brian, I am still working on the radial.

I had a set back when I cut the anulus on the wrong side.

I built the upright and base but I havent had time to do much more, I will post pics on the build log when I get time.

-B-

Enter your email address to join: