JMI

Well-Known Member

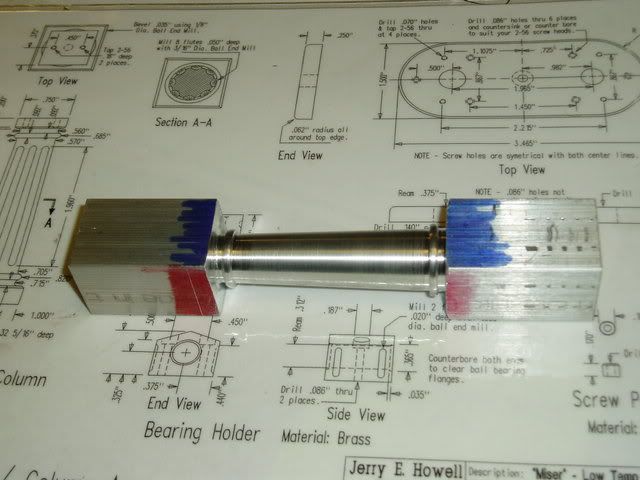

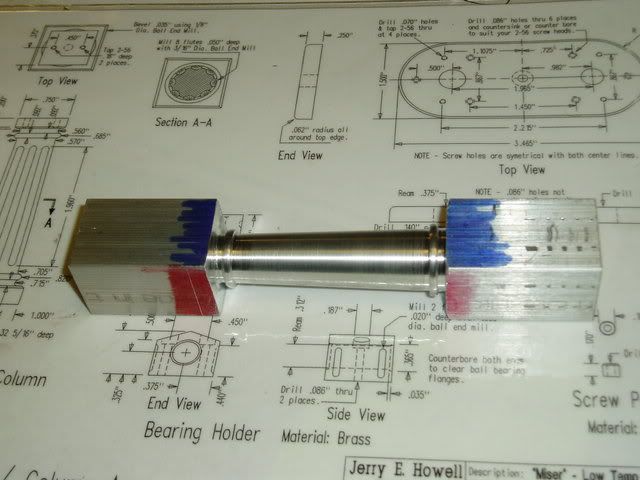

Might as well get this posted as an incentive to carry on till finished. Need to order some ball type end mills to finish the column per (Jerry Howell's) drawings.

Jim

Jim