Mosey

Well-Known Member

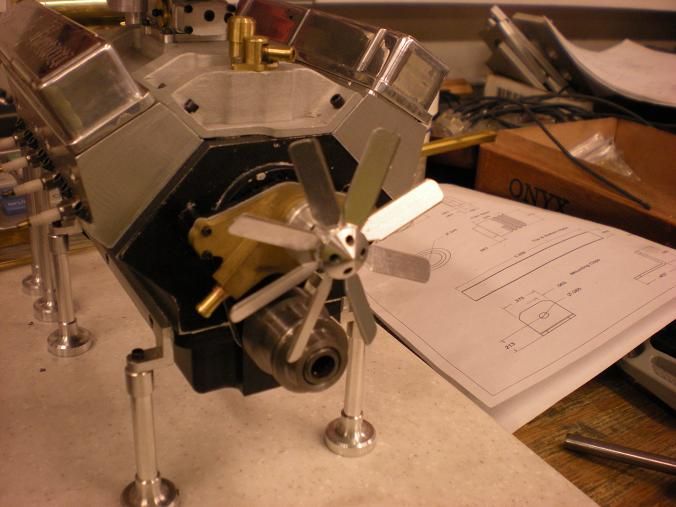

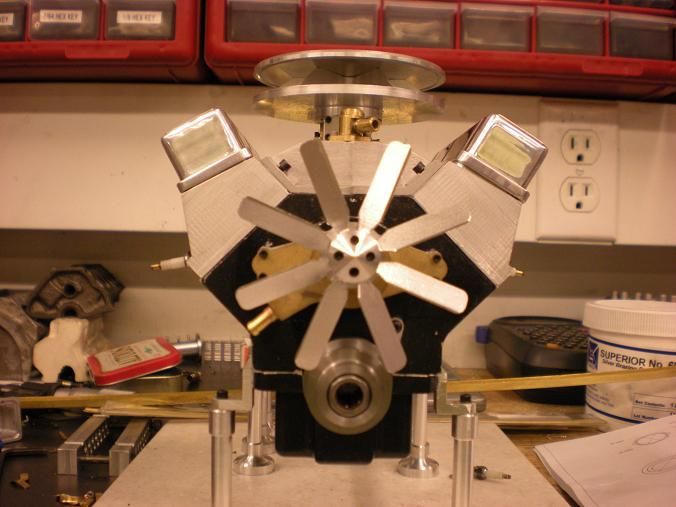

Wow, that is clever. I shall have a look at this method.kcmillin said:Using a shop press and a 3/8" round bar as a die, I pressed the fins curve on. You will need a "Half Hole" equal to the diameter of the Die Rod plus the thickness of the material being used for the fan to act as a female die.

That is how I did it any way.

Kelly

ND