- Joined

- Jun 4, 2008

- Messages

- 3,285

- Reaction score

- 630

You have to have an oops now and then to keep us from having too great an inferiority complex. :

FWIW, you could fix the tubes to the fins with green loctite, which holds up to 400+ degrees.

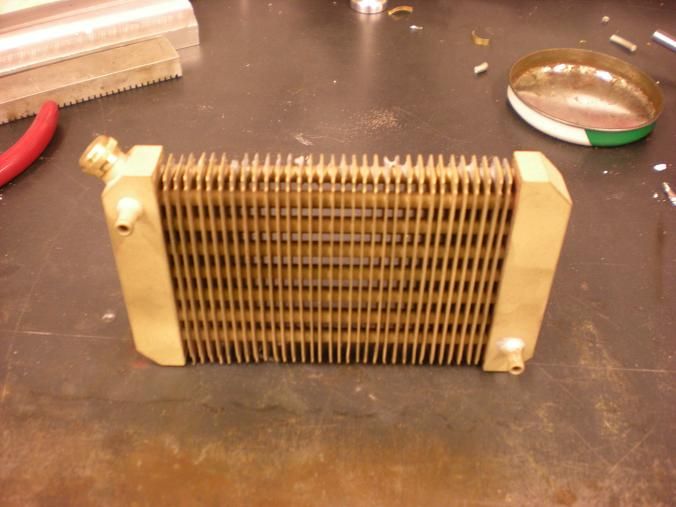

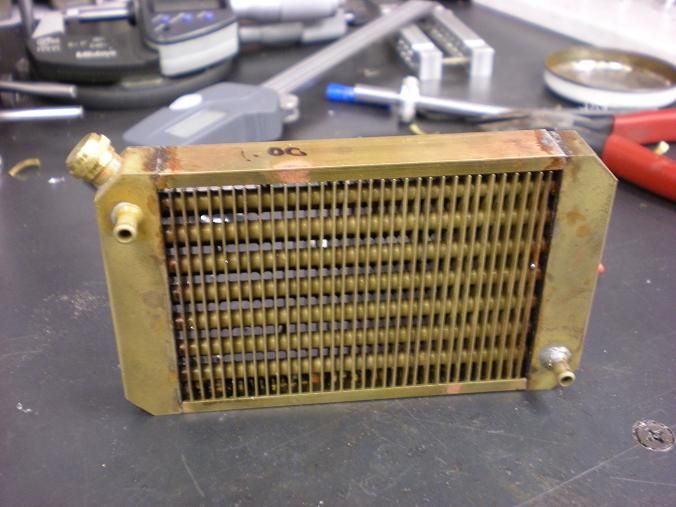

Excellent work.

FWIW, you could fix the tubes to the fins with green loctite, which holds up to 400+ degrees.

Excellent work.