Hello all!

I have hit a creative wall with the straight 8 so I have decided to put it aside and work on something else. This new project is something I have wanted to do for some time. I finally have the plans in good shape, well good enough to start. I like the size of the peewee V4 so i borrowed the 5/8 bore and stroke and will try to build a V8.

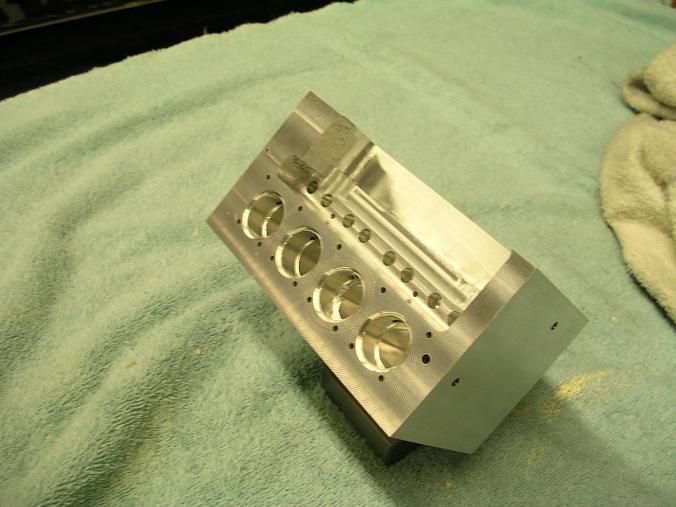

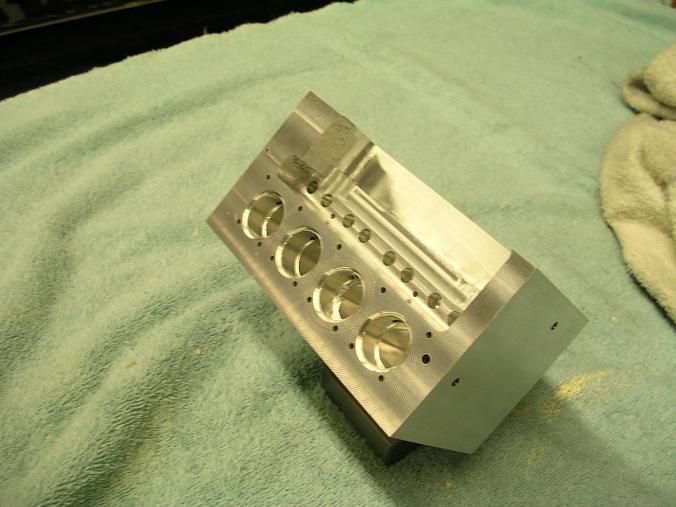

This V8 will be small by most standards. 5/8 bore and stroke. It will have splash oil system and have a coolant system. Unlike Peewee, It will have a more conventional head setup with valve covers. The block will be about 5 inches long with heads at 4.5 inches. I will shoot for 6:1 compression. The cam will be about the same as the peewee as far as lift and duration. Seems like a doable size for smaller equipment.

The down side is that I could only fit # 8 spark plugs in this one so I'll have to make my own. Also the distributor cap sold by Roy is too big so I will have to make my own. The ignition will need to be toned down to control spark.

It will be built using manual equipment and CNC equipment. I know that's a turn off for some but I didn't build a CNC mill so I could look at it across the garage. I'm hoping it will speed things along when making 16 rocker arms or 16 of something else.

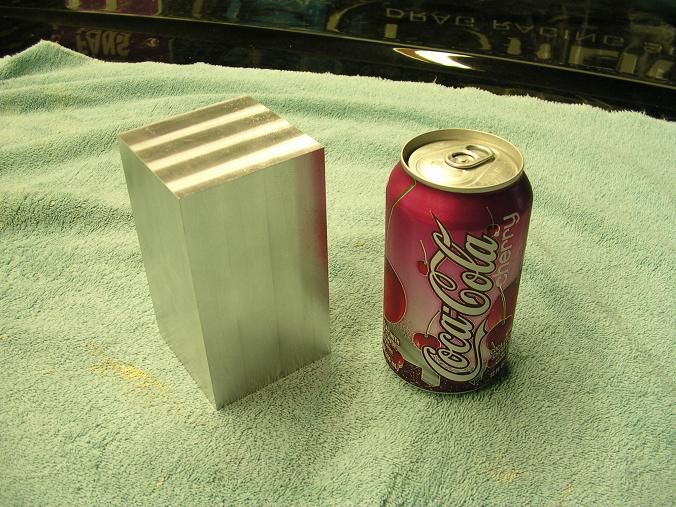

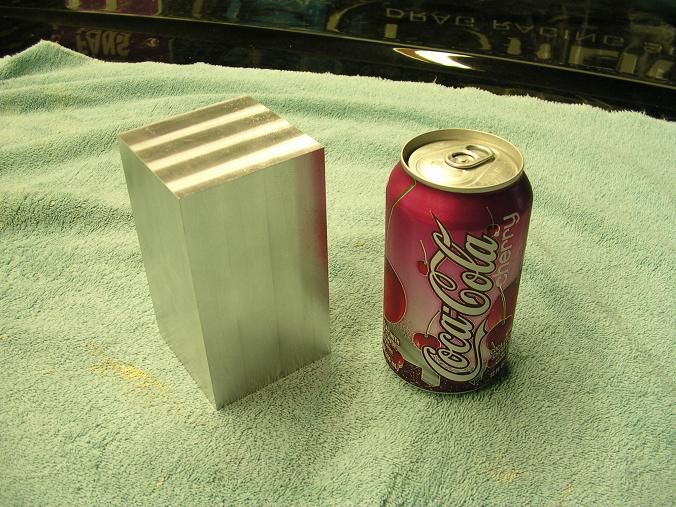

The block is made from a 3 X 3 X 5 block of aluminum.

I have hit a creative wall with the straight 8 so I have decided to put it aside and work on something else. This new project is something I have wanted to do for some time. I finally have the plans in good shape, well good enough to start. I like the size of the peewee V4 so i borrowed the 5/8 bore and stroke and will try to build a V8.

This V8 will be small by most standards. 5/8 bore and stroke. It will have splash oil system and have a coolant system. Unlike Peewee, It will have a more conventional head setup with valve covers. The block will be about 5 inches long with heads at 4.5 inches. I will shoot for 6:1 compression. The cam will be about the same as the peewee as far as lift and duration. Seems like a doable size for smaller equipment.

The down side is that I could only fit # 8 spark plugs in this one so I'll have to make my own. Also the distributor cap sold by Roy is too big so I will have to make my own. The ignition will need to be toned down to control spark.

It will be built using manual equipment and CNC equipment. I know that's a turn off for some but I didn't build a CNC mill so I could look at it across the garage. I'm hoping it will speed things along when making 16 rocker arms or 16 of something else.

The block is made from a 3 X 3 X 5 block of aluminum.