Hello All!!

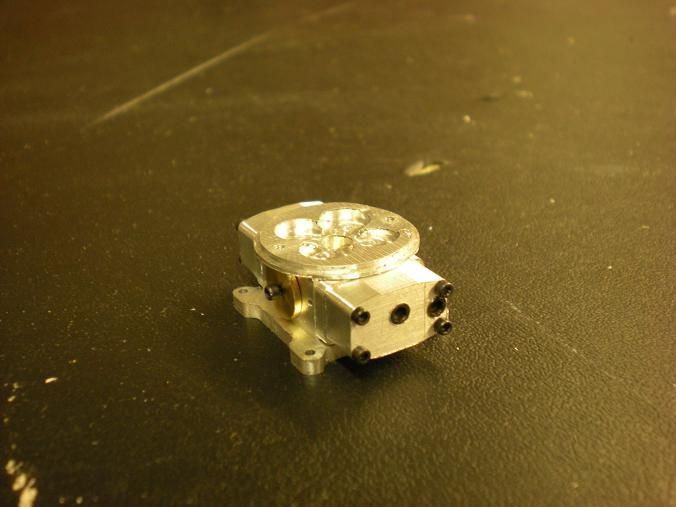

I made the fuel fitting from brass. I found out that if things weren't done in the correct order, I would break the piece every time due to it's small size. I turned the first diameter and threaded it. Cant do this after the hole is drilled and after the .0625 diameter is cut or the piece would just tear itself apart.

Then the rest of the turning gets done.

Then the piece can be drilled thru and parted off.

I still have not decided if I will cut the hex on them. The Peewee had the same fitting and after the tubing is on, You can't see much of the hex anyway.

I made the fuel fitting from brass. I found out that if things weren't done in the correct order, I would break the piece every time due to it's small size. I turned the first diameter and threaded it. Cant do this after the hole is drilled and after the .0625 diameter is cut or the piece would just tear itself apart.

Then the rest of the turning gets done.

Then the piece can be drilled thru and parted off.

I still have not decided if I will cut the hex on them. The Peewee had the same fitting and after the tubing is on, You can't see much of the hex anyway.