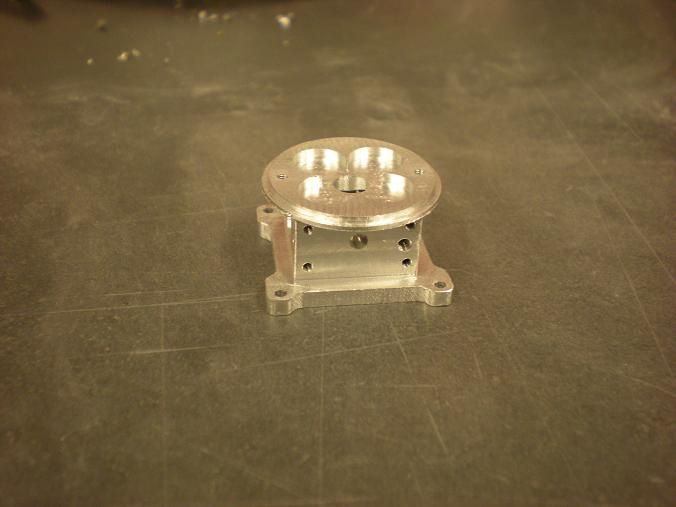

kcmillin said:Them rockers are incredibly complex little parts. :bow: :bow:

How did you hold them when counter boring? It looks like they are on a drill press with no fixture or vice. Is this just an "After" picture?

Kel

Thanks guys!

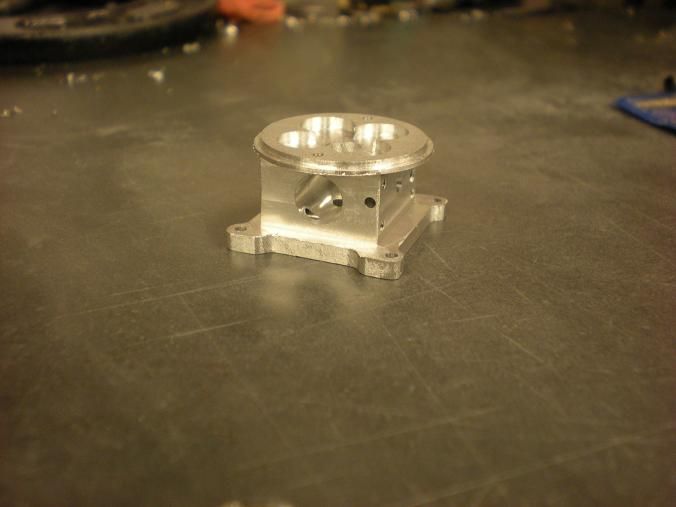

I just held them with my fingers and drilled slow. I wasn't afraid of them getting away from me but if I drill too fast they would heat up.