You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Small V8

- Thread starter stevehuckss396

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

jpeter said:Does the list of parts to be made ever end? Look'n good. Your soon gonna have spark flying everywhere.

Never ends!!

I have Gcode ready to finish the distributor, water pump (2 pcs), water neck, piston bottoms and fixture to cross drill them. It is going to be a fruitful week.

doc1955 said:It really sounds like you are having a blast! And creating some good looking parts!!

I'm working on getting a cnc knee mill I can hardly wait!

When you get the mill, that will be a great day. The months after that suck because you don't know how to make it do anything. Once you figure out how to make the mill move it is super fun. It changes the way you think about this hobby. When you can take 2 of your hobbys and blend them together, it makes both even better.

Fun? Oh yeah!!

doc1955

Gone

- Joined

- Aug 26, 2009

- Messages

- 1,261

- Reaction score

- 163

I have about 25 years of cnc experience so the time to fun curve should be short I hope.

In the beginning of my cnc experience I wrote all the gcode long hand I'll now use Feature cam.

Keep up the good work and don't have all the fun save some :big:

In the beginning of my cnc experience I wrote all the gcode long hand I'll now use Feature cam.

Keep up the good work and don't have all the fun save some :big:

Did some CNC work today.

Started making my water neck that will bolt to the intake and connect a hose to the radiator.

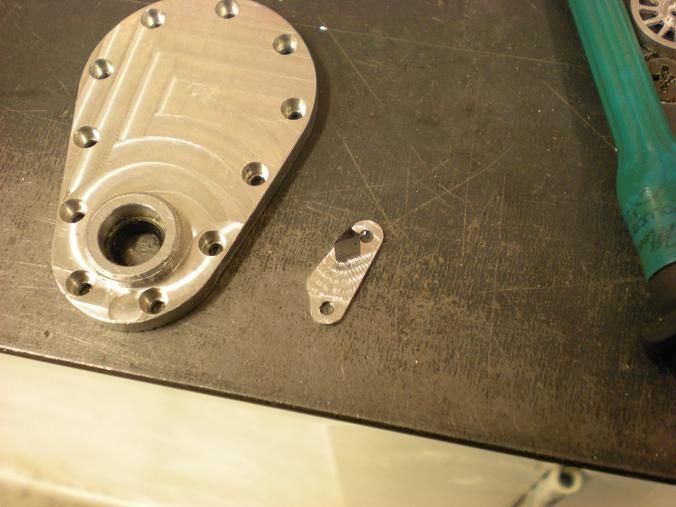

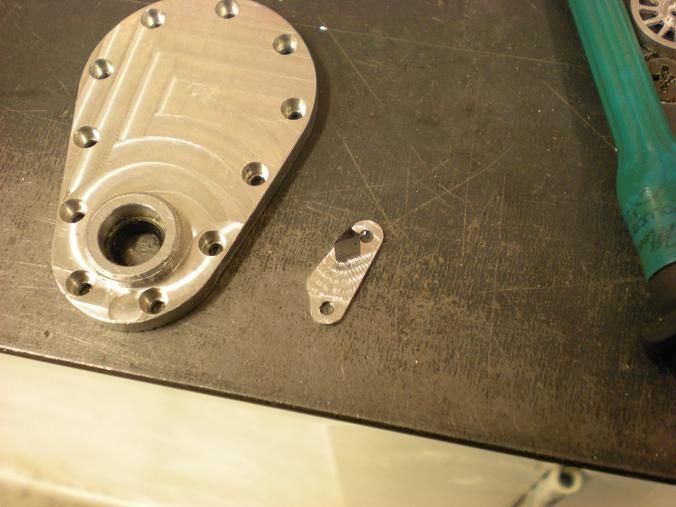

Finished the flanges on my distributor.

Cleaned out the bottom of my pistons.

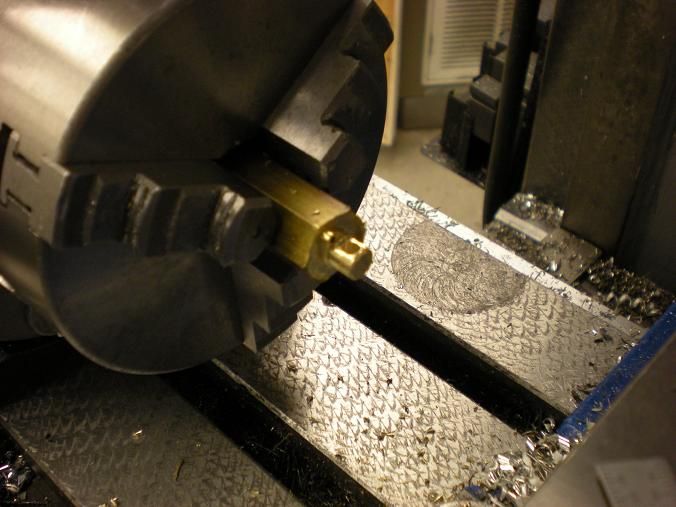

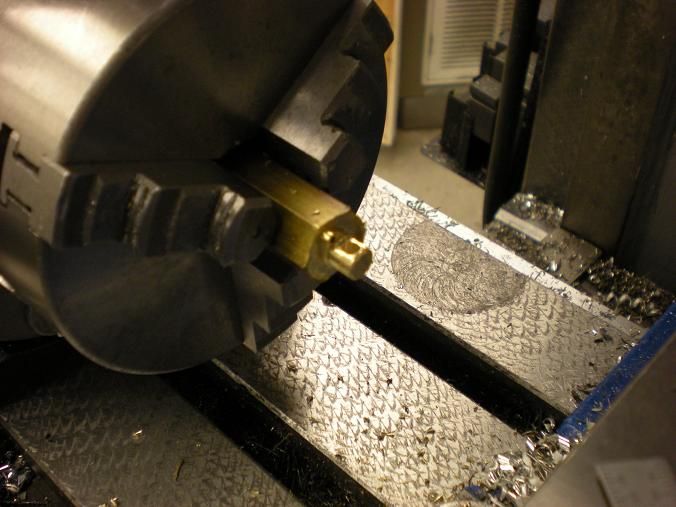

Made the fixture to cross drill the pistons. Simple thing to keep the slot in the bottom and the wrist pin hole square to each other.

Started making my water neck that will bolt to the intake and connect a hose to the radiator.

Finished the flanges on my distributor.

Cleaned out the bottom of my pistons.

Made the fixture to cross drill the pistons. Simple thing to keep the slot in the bottom and the wrist pin hole square to each other.

Lakc

Well-Known Member

Gotta love all the special tools. Sometimes they feel like too much of a distraction but they sure do make the job easier and more accurate.

doc1955 said:Nice little jig to hold you pistons for drilling!

Lakc said:Gotta love all the special tools. Sometimes they feel like too much of a distraction but they sure do make the job easier and more accurate.

The fixture makes the drilling very easy. I can't imagine trying to do all of the pistons any other way.

Finished making a timing pointer so I can keep tabs on where and when the ignition is sparking.

Also made the disk that will hold the magnets to trip the hall sensor.

Finished the water neck. It's hard to tell but I milled a flat and then drilled thru to the center.

Machined up the fitting that the hose will connect to.

Soldered them up from the inside.

Then cleaned out the bottom again with an endmill.

Also made the disk that will hold the magnets to trip the hall sensor.

Finished the water neck. It's hard to tell but I milled a flat and then drilled thru to the center.

Machined up the fitting that the hose will connect to.

Soldered them up from the inside.

Then cleaned out the bottom again with an endmill.

jpeter said:Hey, that manifold with the carb on it looks mighty fine. Fine, so does 80 degrees in the day, 70 at night.

It's always 70F in the garage!!

Lakc

Well-Known Member

Best I can do is low 60's in the basement this time of year. If I try to get it any warmer I will burn out the bearings on the gas meter. :stevehuckss396 said:It's always 70F in the garage!!

Parts are looking pretty good. Are you using multiple magnets in the distributor or single magnets and a shutter?

Lakc said:Are you using multiple magnets in the distributor or single magnets and a shutter?

I'm using 8 magnets. Seems wierd but it is alot easier to build and it works well.

rcfreak177

Well-Known Member

- Joined

- Mar 18, 2010

- Messages

- 324

- Reaction score

- 68

G'day Steve.

I see the V8 build is going well, I have just caught up to speed with the thread, (4 pages worth) The picture of the inlet manifold is great I especially like the tiny water inlet you have made from what looks like brass, You have some real skill to be able to make a part that small with such detail. My V8 has made no more real progress at the moment, I have been working flat out lately as the mining industry in Western Australia is going crazy, my time off is consumed making RC jet components for a guy I have bought parts off in the past. I am looking forward to the future to see and hear your V8 running, definitely an inspiration to me please keep up the great work.

Cheers Barry.

I see the V8 build is going well, I have just caught up to speed with the thread, (4 pages worth) The picture of the inlet manifold is great I especially like the tiny water inlet you have made from what looks like brass, You have some real skill to be able to make a part that small with such detail. My V8 has made no more real progress at the moment, I have been working flat out lately as the mining industry in Western Australia is going crazy, my time off is consumed making RC jet components for a guy I have bought parts off in the past. I am looking forward to the future to see and hear your V8 running, definitely an inspiration to me please keep up the great work.

Cheers Barry.

SNOW DAY!!!!!!!!!!!!!!!!!!!!!!!

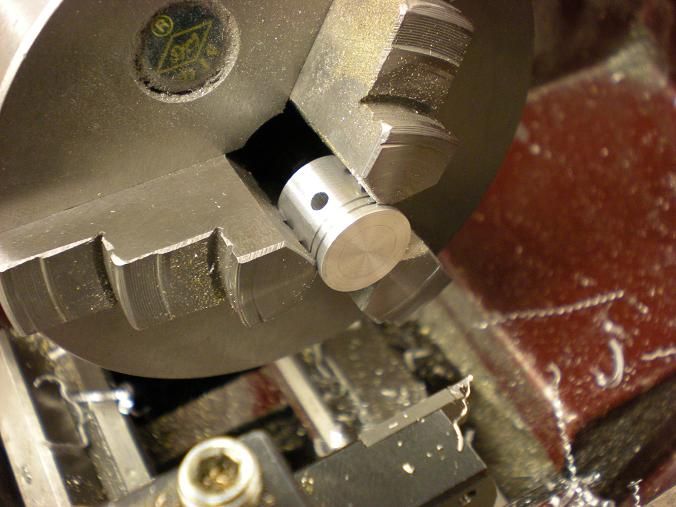

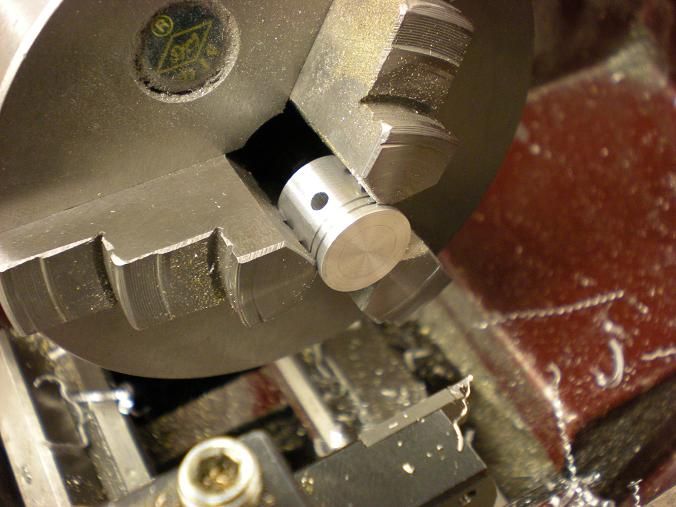

Finished my pistons on this fine day off. Finished the fixture by drilling the wrist pin hole. Drilled .032 larger for clearance.

Then it was spot, drill, ream, repeat.

Then the piston was parted off the little boss. Then VERY lightly they were reversed and finished to height.

I made a few spares in case I made a boo boo. All are useable. They were made from 7075 if anybody is wondering. I had a piece so I used it but 6061 would have been fine also.

I also had time to make the motor mount posts. They are the same as the Peewee mounts. I think I detailed how they were made in that thread.

Finished my pistons on this fine day off. Finished the fixture by drilling the wrist pin hole. Drilled .032 larger for clearance.

Then it was spot, drill, ream, repeat.

Then the piston was parted off the little boss. Then VERY lightly they were reversed and finished to height.

I made a few spares in case I made a boo boo. All are useable. They were made from 7075 if anybody is wondering. I had a piece so I used it but 6061 would have been fine also.

I also had time to make the motor mount posts. They are the same as the Peewee mounts. I think I detailed how they were made in that thread.

Lakc

Well-Known Member

Glad to see you were productive while the rest of us braved the ice and snow and idiots on the roads this morning.

Lakc said:Glad to see you were productive while the rest of us braved the ice and snow and idiots on the roads this morning.

I had no chance at all. I had 12 inches in my driveway with branches from my neighbors tree on top of that. Plow still has not gone by.

BlakeMcKee

Active Member

- Joined

- Oct 20, 2010

- Messages

- 41

- Reaction score

- 0

stevehuckss396 said:I had no chance at all. I had 12 inches in my driveway with branches from my neighbors tree on top of that. Plow still has not gone by.

Guess I should feel guilty for our 75-80 degree week! :big:

BlakeMcKee said:Guess I should feel guilty for our 75-80 degree week! :big:

I wouldn't. I never feel guilty when it's over 100F and we are at 75F. My brother inlaw called from SC laughing. I told him to call back in August.

Similar threads

- Replies

- 413

- Views

- 39K