- Joined

- Jun 24, 2010

- Messages

- 2,359

- Reaction score

- 931

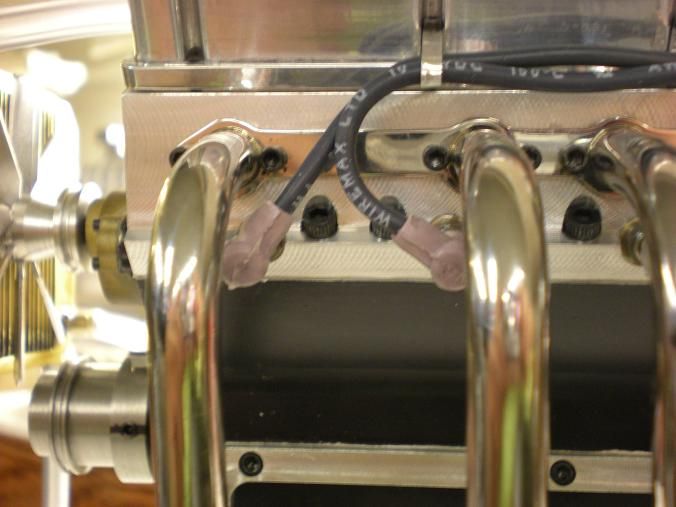

Hi Steve. Way back when you made your piston rings, you mentioned 500F for coating stage, then 4 hrs @1100F for the heat set stage. May I ask what kind of oven system you use/recommend for jobs like this? Do you also use this for heat treating self made tool steel type applications as well?