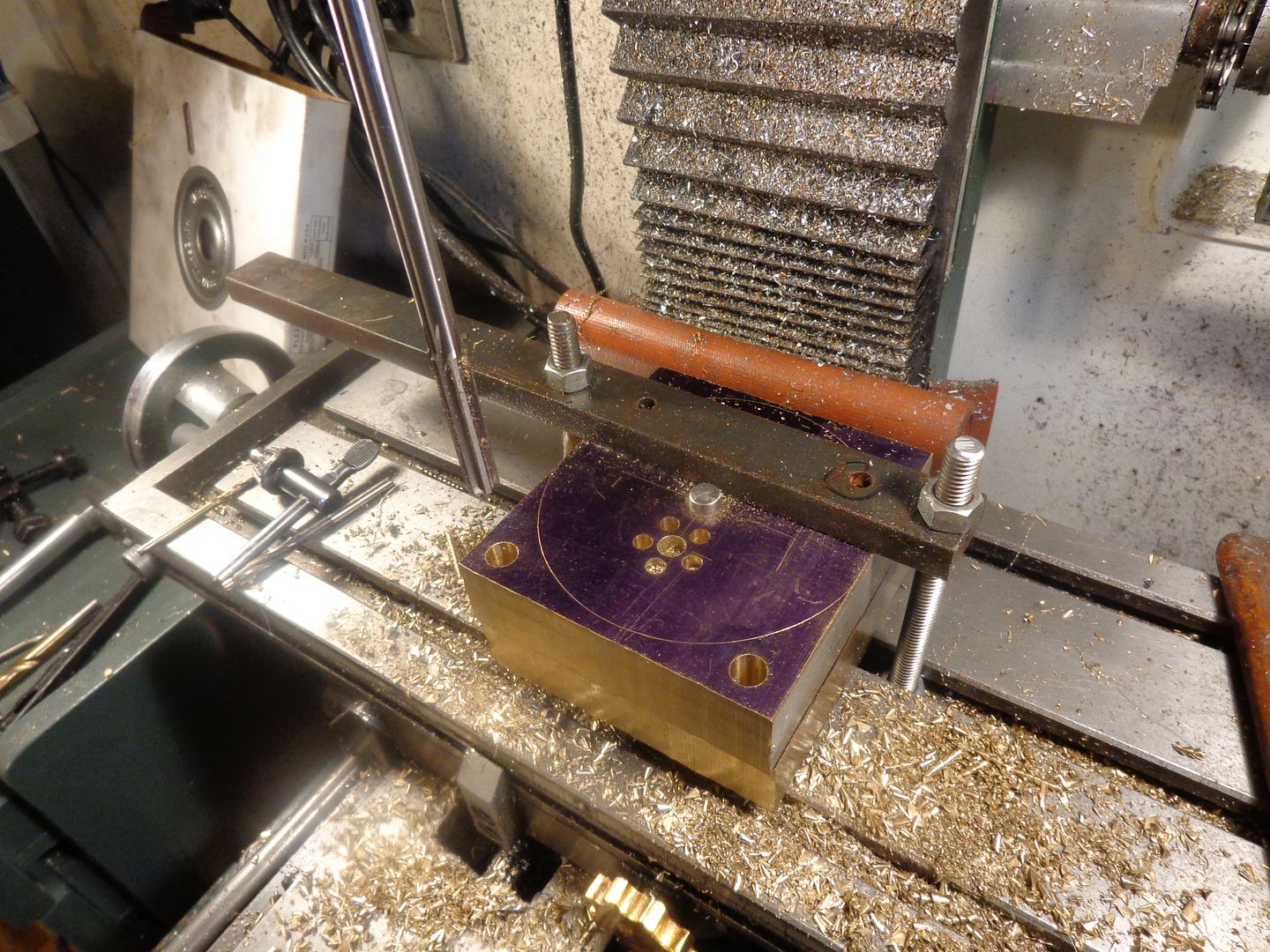

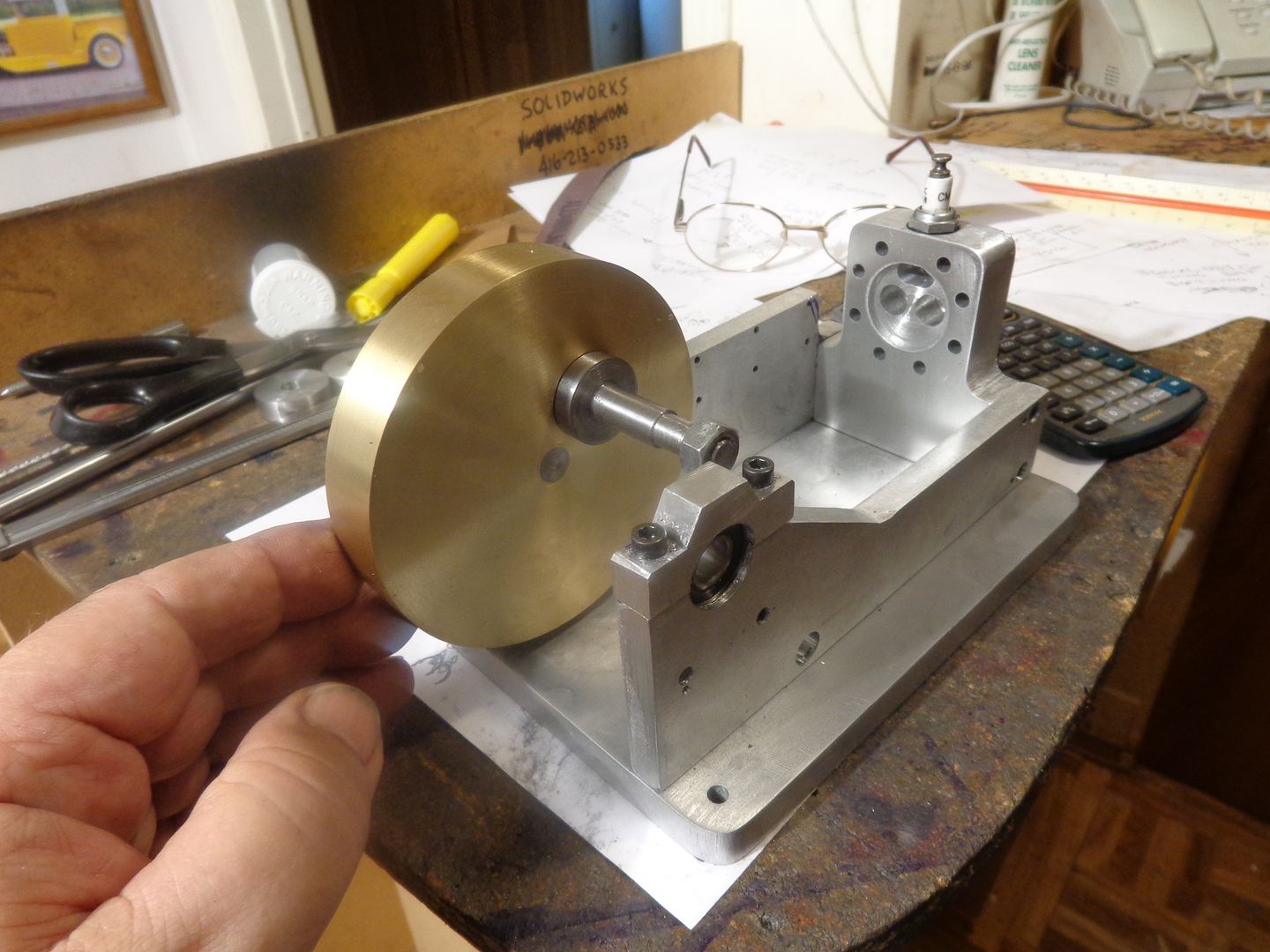

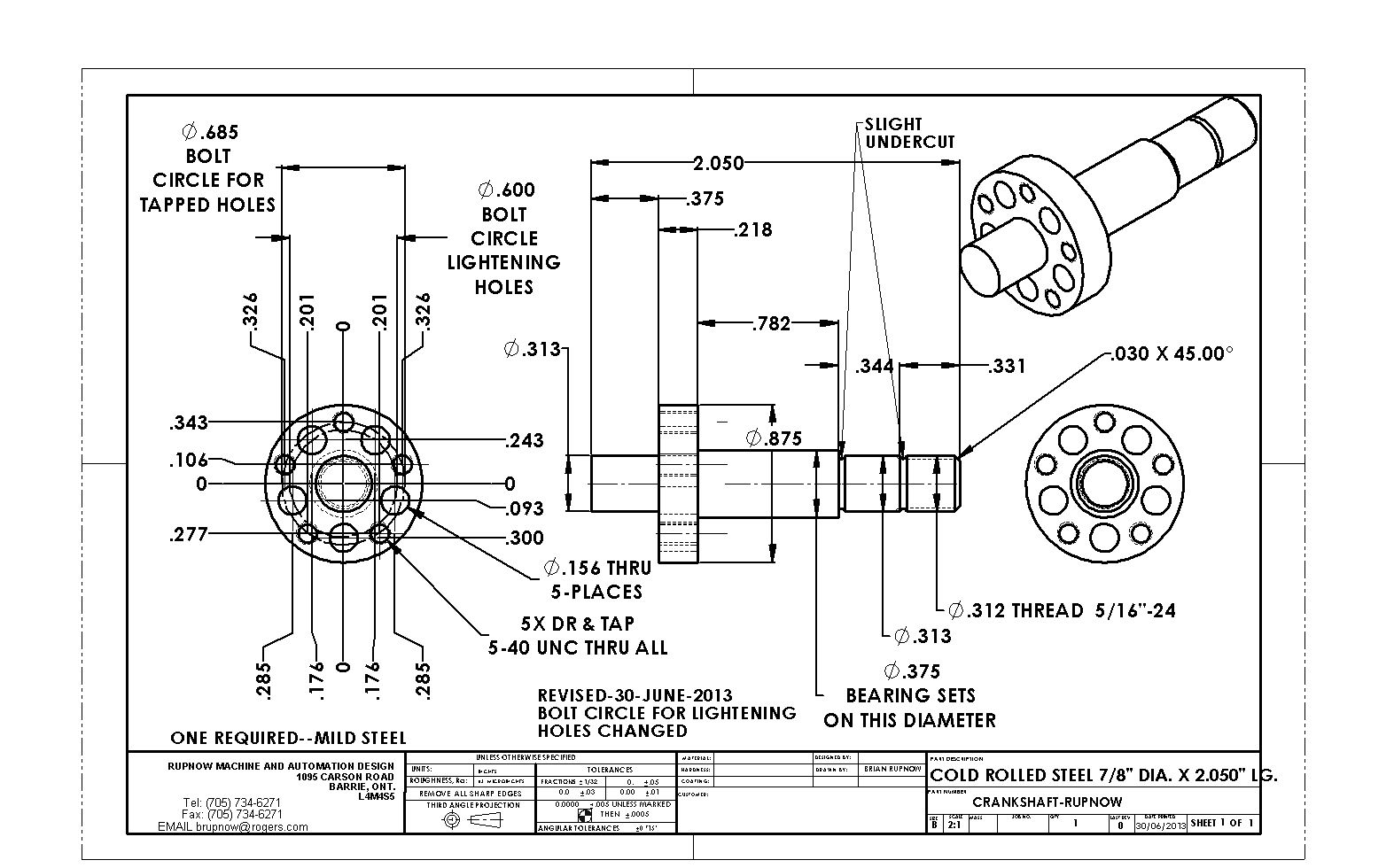

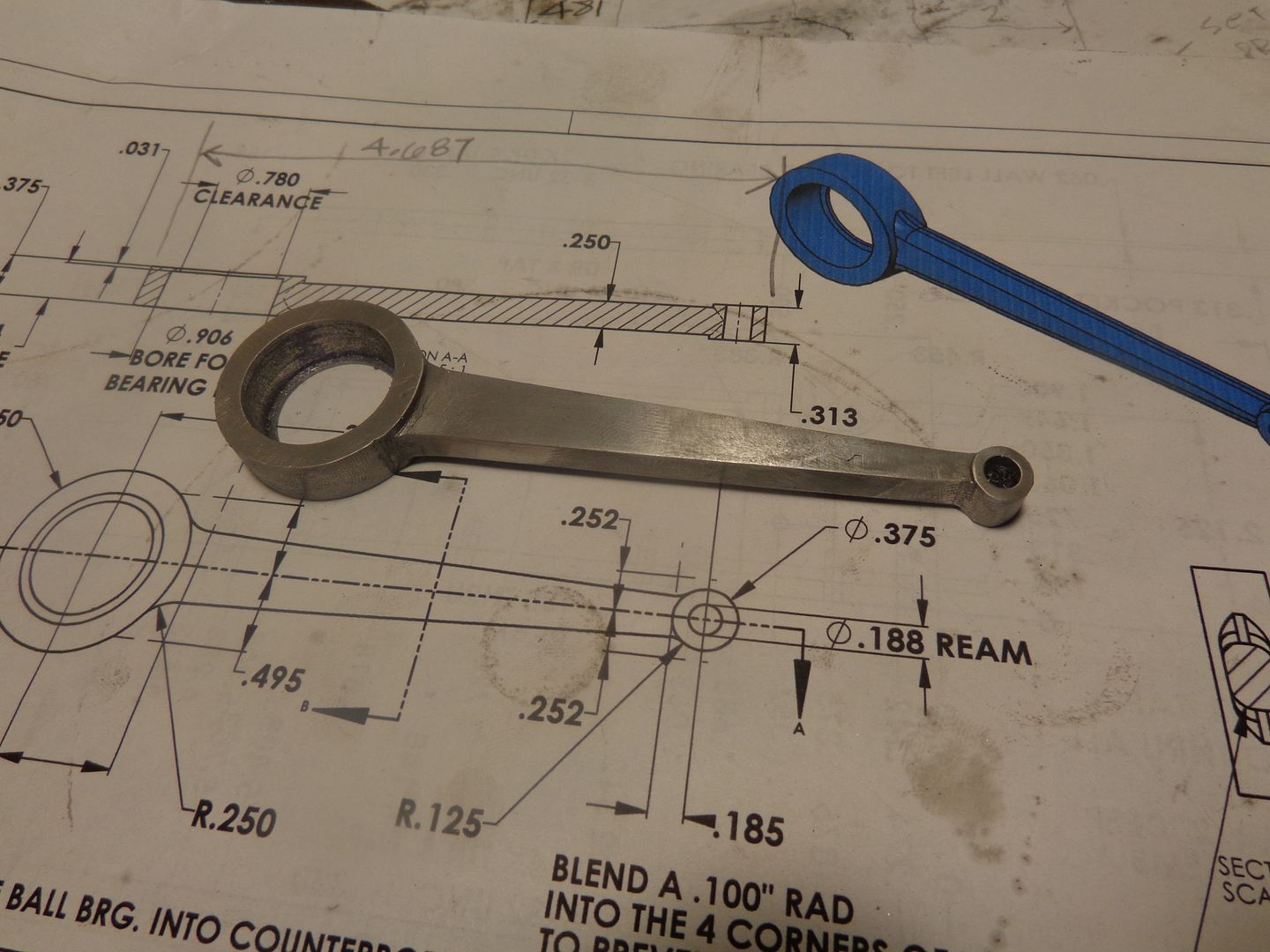

Allright!!! ---I have put out my customers various engineering panic related fires, and now its time to do some serious flywheeling. Damn, I hate it when REAL WORK interferes with my "play work"---but then again, that's how I can afford brass for my flywheels. I am trying to come up with a good plan of attack for these flywheels. Since I am making them from brass bar, I think I will lay out the two flywheels on the bar, then clamp the bar to the table of my mill with a piece of sacrificial aluminum under it. I will then drill and ream the two undersized center holes. This will ensure that the holes are at perfect right angles to the face of the bar in both planes. Then I will remove the bar, saw it in half, turn a slightly undersized center alignment shaft to put through the undersized holes, and clamp the double thickness of bar to my mill table again with a bit of sacrificial aluminum under them, and drill and ream the two .75" offset holes for the crankpin at the same time. Then I will remove them from the table and separate them, saw out the rough 4" diameters on my bandsaw and press in an extra long 3/8" shaft on each one, allowing about 2" of shaft to stick out on the "blank" side of the flywheel. This will give me something to hold onto with the chuck while I turn the o.d. to an exact 4" diameter and do the machining required on the face of each blank. When the metal supplier went to cut a piece of 4" x 3/4" brass flatbar for me, he found that all he had was 4" x 1" flatbar, so he gave it to me for the same price. This means I get to do a clean-up cut on the flat side which has no features. Then I will cut off the "extra long" bit of shaft in the lathe.

Last edited: