Petertha. No offence meant at all. I was just observing that "making" a distributor cap from using CAD to draw what you want and then a CAD-CAM machine or plastic printer, is just not the same as hands-on milling, drilling, turning etc. that you are doing - because that's what you enjoy, and CAN do.

I draw with Pencil, tee-square, paper, etc, use saws and files and lathes , drilling machines, millers, etc. - Then go and buy proprietary nuts and bolts, etc. because they are cheaper (and BETTER!) than I can make. But CAD doesn't excite me... 4 years in Design with a trammel board allowed me to think in a way I don't with CAD. Don't get me wrong, I don't knock technology, because it takes us so much faster to new ideas and solutions than old technology for design and manufacture. But CAD feels to me like buying bits someone else had designed and made and just bolting then together (inside the computer) so when you send it to the CNC machine or 3D printer the machine makes the bits - NOT ME! And I enjoy the hours removing metal to make something, just the same as the hours spent fishing in case a fish wanders by and takes the bait.... It is the occupation, not the final object that satisfies. Not just the "fish on the plate". I think we are of a similar ideology. We choose what we make, and buy bits we are less interested (or able?) in making.

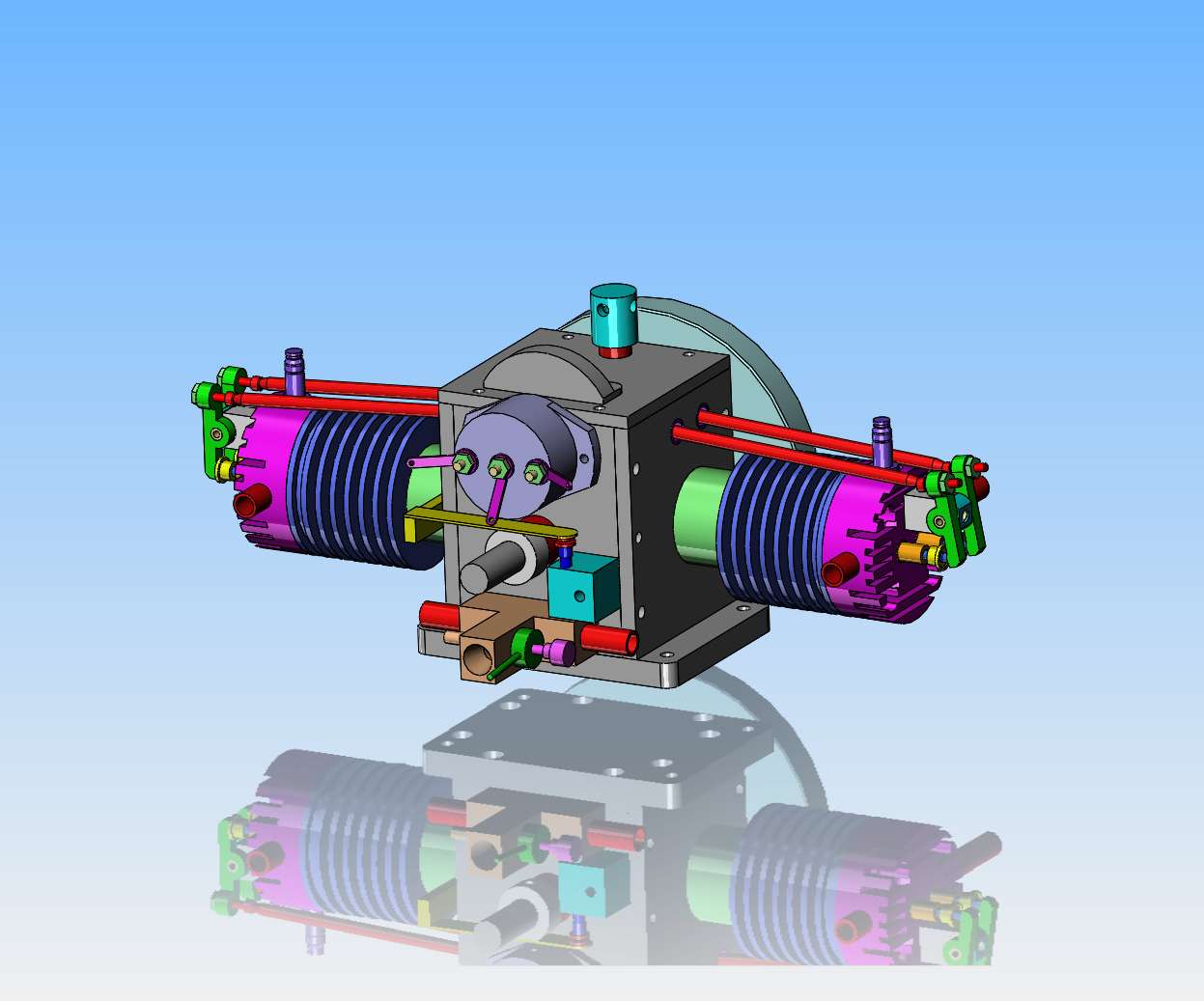

K2