GBritnell gave me the heads up on "1144 stress proof steel". After working with it, it is the stuff. Try to find yourself a cut in the size you need and you will be converted like me. Strong but easy to work with and very little warpage.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rattler

- Thread starter metalmad

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I have found that 1144 SP is the steel for crankshafts but I don't know about it's availability in the UK and Aus. The plans call out for 1144 but I know of people using 1050 shafting also. I don't like CRS 1018 because it's to soft and doesn't wear well and has a tendency for warpage. By the way Pete, your Rattler is really taking shape now. Very nice, Dave

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

Hi guys

When I asked for 1144 SP the look on the guys face was priceless :big:

It turns out he had Bright or Hi tensile (take your pick )

I decided to keep going with the HT and using a very good quality half inch bit was able to take another couple of bites of the Elephant.

once Ive roughed it out I will put it aside for a few days to warp a bit

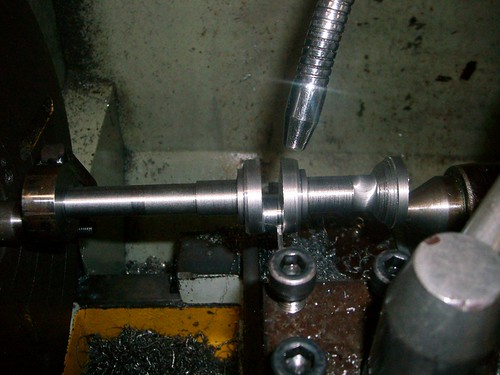

SANY1680 by metalmad2011, on Flickr

Pete

When I asked for 1144 SP the look on the guys face was priceless :big:

It turns out he had Bright or Hi tensile (take your pick )

I decided to keep going with the HT and using a very good quality half inch bit was able to take another couple of bites of the Elephant.

once Ive roughed it out I will put it aside for a few days to warp a bit

SANY1680 by metalmad2011, on Flickr

Pete

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

Started roughing the main journal today

This material is a bit softer towards the center thank goodness :big:

SANY1682 by metalmad2011, on Flickr

This material is a bit softer towards the center thank goodness :big:

SANY1682 by metalmad2011, on Flickr

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

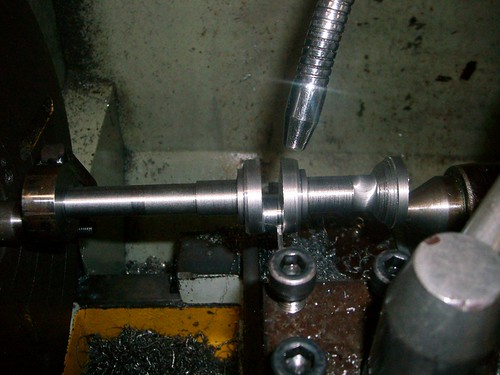

got a little more done and will take the mains down close tomorrow and then put it aside till next week when I plan on finishing to size.

SANY1683 by metalmad2011, on Flickr

Pete

SANY1683 by metalmad2011, on Flickr

Pete

Hi Pete, your crankshaft looks great. I think you have a good plan to let it set for awhile before finishing. I remember machining some parts as an apprentice once and upon returning to work the next day they weren't as straight as I left them the day before. Warpage does happen. A small suggestion from experience, I don't make the rod and piston until last, this keeps me from putting the parts together and fiddling with them before everything is cleaned real well. I damaged a piston once by playing with it in the bore before I should have. Just something to think about and I have made this a habit on all my engines I build.

I'm impressed by your progress and can't wait for the big day it goes bang, Dave

I'm impressed by your progress and can't wait for the big day it goes bang, Dave

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

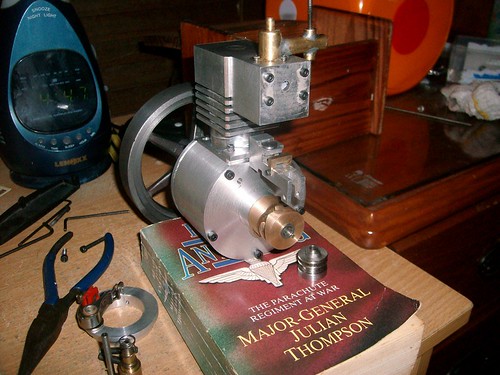

Today I roughed out the main shaft and am resting it now till Monday, and to think I used to throw out those broken Stump Grinder teeth. :big:

As I want to fit the Flywheel Monday, I thought today might be a good time to start one. :big:

SANY1685 by metalmad2011, on Flickr

SANY1684 by metalmad2011, on Flickr

Im having a go at a Casting for the first time and am amazed with the Speed a flywheel can be made. :big:

As I want to fit the Flywheel Monday, I thought today might be a good time to start one. :big:

SANY1685 by metalmad2011, on Flickr

SANY1684 by metalmad2011, on Flickr

Im having a go at a Casting for the first time and am amazed with the Speed a flywheel can be made. :big:

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

Hi Tel

The Flywheel Casting and the crossover cam were sent to me by Dave G.

He even offered to send me some stress proof for the Crank when I Started to get into trouble with the Hi tensile.

As it turns out the H/T seems to be turning out well, but I guess I will know how well on Monday.

Now is as good a time as any to say how Honered I am to be given the first build of this lovely and unique little motor.

For a Novice to be allowed this privilege, is for me a wonderful thing, Dave has been a "Tool maker" for something like 30 years or so and he knows his Stuff, He could have easily built it himself and done a much better job too.

His Crankshaft on the prototype is a 3 piece job with the weights dovetailed onto the Crank. It did not even cross my mind to try it :big:

Pete

SANY1686 by metalmad2011, on Flickr

The Flywheel Casting and the crossover cam were sent to me by Dave G.

He even offered to send me some stress proof for the Crank when I Started to get into trouble with the Hi tensile.

As it turns out the H/T seems to be turning out well, but I guess I will know how well on Monday.

Now is as good a time as any to say how Honered I am to be given the first build of this lovely and unique little motor.

For a Novice to be allowed this privilege, is for me a wonderful thing, Dave has been a "Tool maker" for something like 30 years or so and he knows his Stuff, He could have easily built it himself and done a much better job too.

His Crankshaft on the prototype is a 3 piece job with the weights dovetailed onto the Crank. It did not even cross my mind to try it :big:

Pete

SANY1686 by metalmad2011, on Flickr

bezalel2000

Well-Known Member

- Joined

- May 8, 2011

- Messages

- 316

- Reaction score

- 7

That's starting to look like a Lister spare parts counter :big:

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

Hi Bez yea its starting to build up now, u should hear what the wife says about my parts everywhere :big:

Hi Dave

yep its a gearless Hit n Miss and uses a Crossover Cam, I will quote directly from Dave G about the Cam.

"The Crossover cam basically is a slot in a round piece that crosses over at one point and then crosses back over on the next revoltion. If you put a stylus in this slot it takes 720 degrees of rotation to get back to where you started. An exhaust cam is placed next to the crossover to allow a roller follower to ride up on the cam on one revolution but clears the cam on the next"

its a fancy 2/1 ratio mechanism

Pete

Hi Dave

yep its a gearless Hit n Miss and uses a Crossover Cam, I will quote directly from Dave G about the Cam.

"The Crossover cam basically is a slot in a round piece that crosses over at one point and then crosses back over on the next revoltion. If you put a stylus in this slot it takes 720 degrees of rotation to get back to where you started. An exhaust cam is placed next to the crossover to allow a roller follower to ride up on the cam on one revolution but clears the cam on the next"

its a fancy 2/1 ratio mechanism

Pete

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

The installation of the Crank is a great day in the build of an engine and marks the point where parts become a motor.

In anticipation of that upcoming event, I bolted the Block together today :big:

SANY1687 by metalmad2011, on Flickr

Pete

In anticipation of that upcoming event, I bolted the Block together today :big:

SANY1687 by metalmad2011, on Flickr

Pete

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

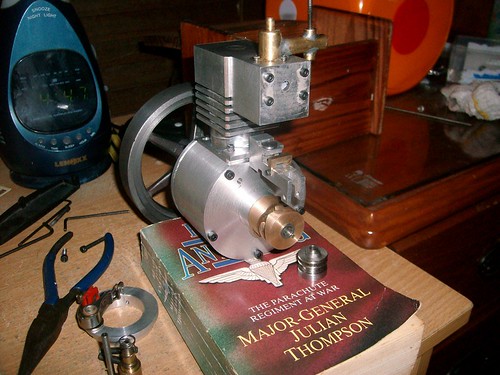

Before some bright spark asks why the Carby faces the other way now I'll tell u.

I was trying to work out how to use the "PCD" function on the DRO and was so wrapped up in start and finish angles etc etc that I just did not notice I got the D### thing 180 degrees out )

)

I will just make the exhaust go the other way and nobody will ever know :big:

SANY1689 by metalmad2011, on Flickr

Pete

I was trying to work out how to use the "PCD" function on the DRO and was so wrapped up in start and finish angles etc etc that I just did not notice I got the D### thing 180 degrees out

I will just make the exhaust go the other way and nobody will ever know :big:

SANY1689 by metalmad2011, on Flickr

Pete

Similar threads

- Replies

- 13

- Views

- 691