Hi Pete, Looking good so far. I really admire your intestenal fortitude for taking on this project. I'm sure we all are aware of the difficulties of doing a project like this and hopefully everyone will be here to help. I know I will be. It's the first time around the block with this engine and there will be roadbumps.

As for plans, I have the component prints drawn with Turbocad, machining instructions, bill of materials, and purchased parts list. Once Pete has finished his engine and the prints are proven to be correct they will be available. This is my first attempt at documenting one of my engines so please be patient. For those that have done this, my hats off to you because it's alot of work. Because of the amont of time invested I will charge a minimal fee for the plans. Believe me, my goal is not to get rich from this and I think the info in the plans will be a good value in the end.

I tried to design this engine with the novice machinist in mind. It's a 4 stroke design with no gears. I'm hoping it will become a good first IC engine project for those interested or just something a little different on the shelf for those who have built before..

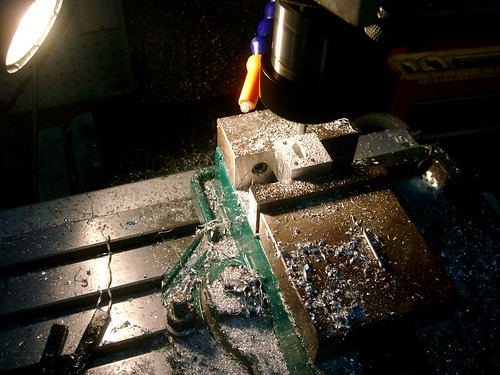

Looks like Pete's off to a good start and I thank you Pete for everything you are doing. Dave