- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

Hi Larry

I recon Its still at least a month off yet before its even close to the running stage but stay tuned.

I plan to put at least a couple of videos up as i did with the "Sow"(3) but before that happens there are a lot of little Governor parts to be made, mostly out of Stainles Steel, not to even mention piston and conrod ;D

Thank you for the assumption That it will run :big:

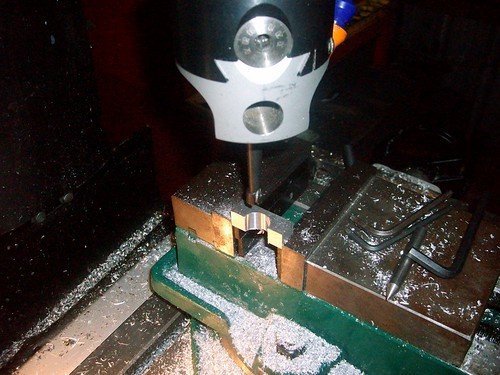

I hope to continue work on the Crank today

Pete

I recon Its still at least a month off yet before its even close to the running stage but stay tuned.

I plan to put at least a couple of videos up as i did with the "Sow"(3) but before that happens there are a lot of little Governor parts to be made, mostly out of Stainles Steel, not to even mention piston and conrod ;D

Thank you for the assumption That it will run :big:

I hope to continue work on the Crank today

Pete