You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rattler

- Thread starter metalmad

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

Hi Dave

I Stuffed up today and picked up the wrong drill and drilled to tap 4-40 on the Gov trip instead of 2-56.

mornings work gone

I did something fun to make myself feel better ;D

http://www.flickr.com/photos/61672544@N06/5741933851/

A start on the Crankcase. (video)

Pete

I Stuffed up today and picked up the wrong drill and drilled to tap 4-40 on the Gov trip instead of 2-56.

mornings work gone

I did something fun to make myself feel better ;D

http://www.flickr.com/photos/61672544@N06/5741933851/

A start on the Crankcase. (video)

Pete

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

Well Dave U may have to wait a while the way I'm going the last few days

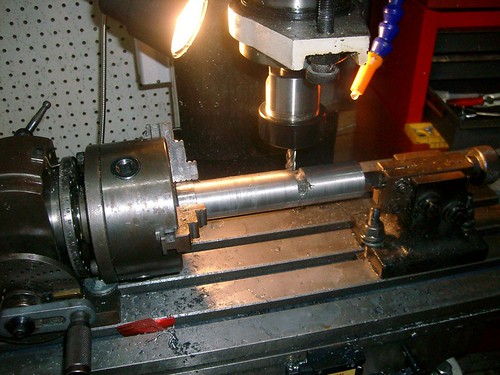

Today I made the Spool and spindle out of Stainless Steel.

After making the spindle, I then drilled and reamed the Spool(Bobbin) I even lapped it in,

so that the spindle had a nice sliding fit, after that I used my parting off tool to do the grooves and parted it off.

part done

I then noticed the spindle would no longer fit the bore of the Spool, so carefully put it in the vice and began to ream it again.

The parting tool must have coursed the bore to close up cos when I reamed it the dame thing broke

I guess the Spool has to be drilled,and reamed after doing the grooves and then parted

SANY1660 by metalmad2011, on Flickr

Today I made the Spool and spindle out of Stainless Steel.

After making the spindle, I then drilled and reamed the Spool(Bobbin) I even lapped it in,

so that the spindle had a nice sliding fit, after that I used my parting off tool to do the grooves and parted it off.

part done

I then noticed the spindle would no longer fit the bore of the Spool, so carefully put it in the vice and began to ream it again.

The parting tool must have coursed the bore to close up cos when I reamed it the dame thing broke

I guess the Spool has to be drilled,and reamed after doing the grooves and then parted

SANY1660 by metalmad2011, on Flickr

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

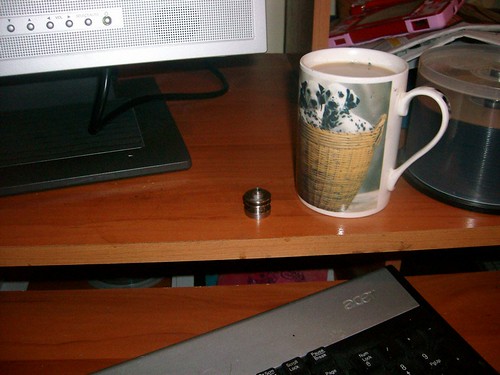

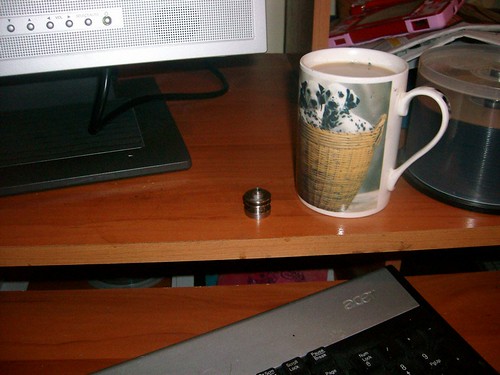

Had a chance to remake the Spool this arvo

SANY1662 by metalmad2011, on Flickr

This bit of Stainless was nothing like the last bit and was very very tough

Pete

SANY1662 by metalmad2011, on Flickr

This bit of Stainless was nothing like the last bit and was very very tough

Pete

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

Maybe I should start looking for a bigger box :big:

SANY1667 by metalmad2011, on Flickr

SANY1665 by metalmad2011, on Flickr

SANY1668 by metalmad2011, on Flickr

pete

SANY1667 by metalmad2011, on Flickr

SANY1665 by metalmad2011, on Flickr

SANY1668 by metalmad2011, on Flickr

pete

bezalel2000

Well-Known Member

- Joined

- May 8, 2011

- Messages

- 316

- Reaction score

- 7

Hay Pete

Your pretty much past half way, by the looks.

How many bits are left to make before you can assemble? and make smoke!!

Bez

Your pretty much past half way, by the looks.

How many bits are left to make before you can assemble? and make smoke!!

Bez

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

Hi Bez

there are still a fair few little bits and pieces, but im hoping to get the block ends done or at least started tomorrow and sorta planing to really hit it on sunday and start the crank.

I recon by the end of next week it will start to look like a motor :big:

Pete

PS

I sure hope it does not smoke too much

there are still a fair few little bits and pieces, but im hoping to get the block ends done or at least started tomorrow and sorta planing to really hit it on sunday and start the crank.

I recon by the end of next week it will start to look like a motor :big:

Pete

PS

I sure hope it does not smoke too much

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

Hi Dave

I dont know if the Rat will run as well as yours does mate, but it is going to run 8)

even if I have to remake every bit in it :big:

Today I got one endplate done and locktighted in the bush.

I will leave it in the lathe till tomorrow and then bore the bush.

SANY1670 by metalmad2011, on Flickr

SANY1673 by metalmad2011, on Flickr

Pete

I dont know if the Rat will run as well as yours does mate, but it is going to run 8)

even if I have to remake every bit in it :big:

Today I got one endplate done and locktighted in the bush.

I will leave it in the lathe till tomorrow and then bore the bush.

SANY1670 by metalmad2011, on Flickr

SANY1673 by metalmad2011, on Flickr

Pete

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

Here is the first endcap, the second is still in the lathe letting the locktight on the bush cure

endcap by metalmad2011, on Flickr

looking good for a start on the crank tomorrow ;D

Pete

endcap by metalmad2011, on Flickr

looking good for a start on the crank tomorrow ;D

Pete

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

Hi Tel

I wonder if i can get by without a Crank?

cos whatever that guy sold me the other day, I'm gunna need new bits etc to turn it Obvously very Hi tensile.

Obvously very Hi tensile.

I tryed shortening the tool and tightening those umbrako bolts on the twirly thingo mo bob and the tool still chattered. Then I put it in the Mill and melted a 3/8 bit trying to make a slot for the journal.

SANY1677 by metalmad2011, on Flickr

SANY1677 by metalmad2011, on Flickr

my poposed solution )

)

SANY1679 by metalmad2011, on Flickr

I wonder if i can get by without a Crank?

cos whatever that guy sold me the other day, I'm gunna need new bits etc to turn it

I tryed shortening the tool and tightening those umbrako bolts on the twirly thingo mo bob and the tool still chattered. Then I put it in the Mill and melted a 3/8 bit trying to make a slot for the journal.

SANY1677 by metalmad2011, on Flickr

SANY1677 by metalmad2011, on Flickr

my poposed solution

SANY1679 by metalmad2011, on Flickr

- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

tel

Well-Known Member

- Joined

- Feb 8, 2008

- Messages

- 3,293

- Reaction score

- 44

I'm still bushless! ;D

Similar threads

- Replies

- 13

- Views

- 692