If you join the bulletin board on the Logan site you will get a lot of info from people with Logan/Wards lathes that have been modified in every conceivable way.

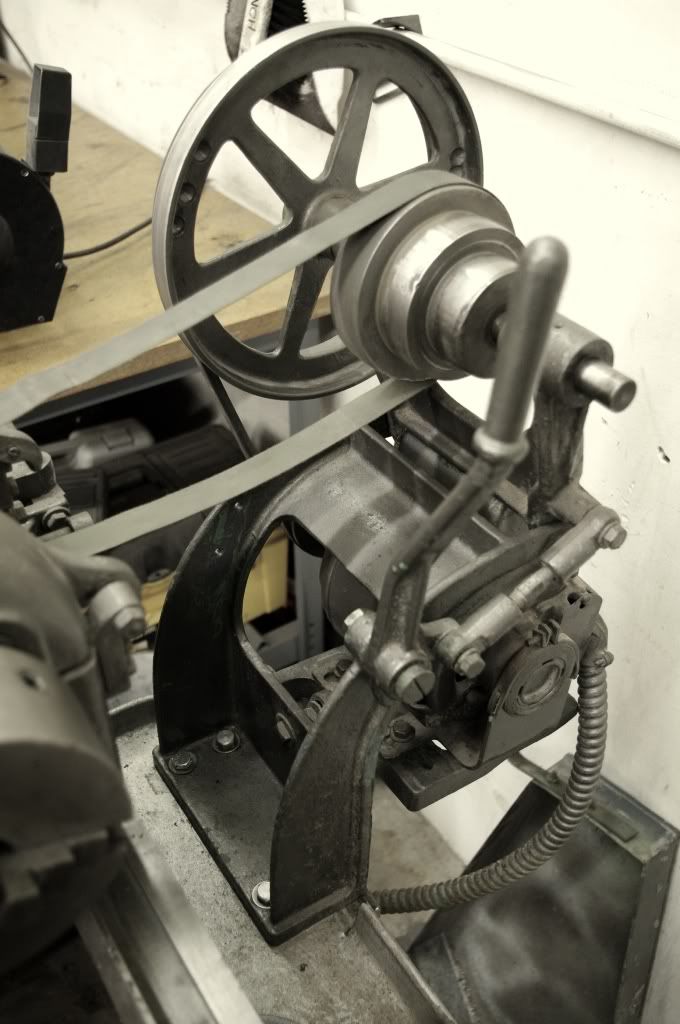

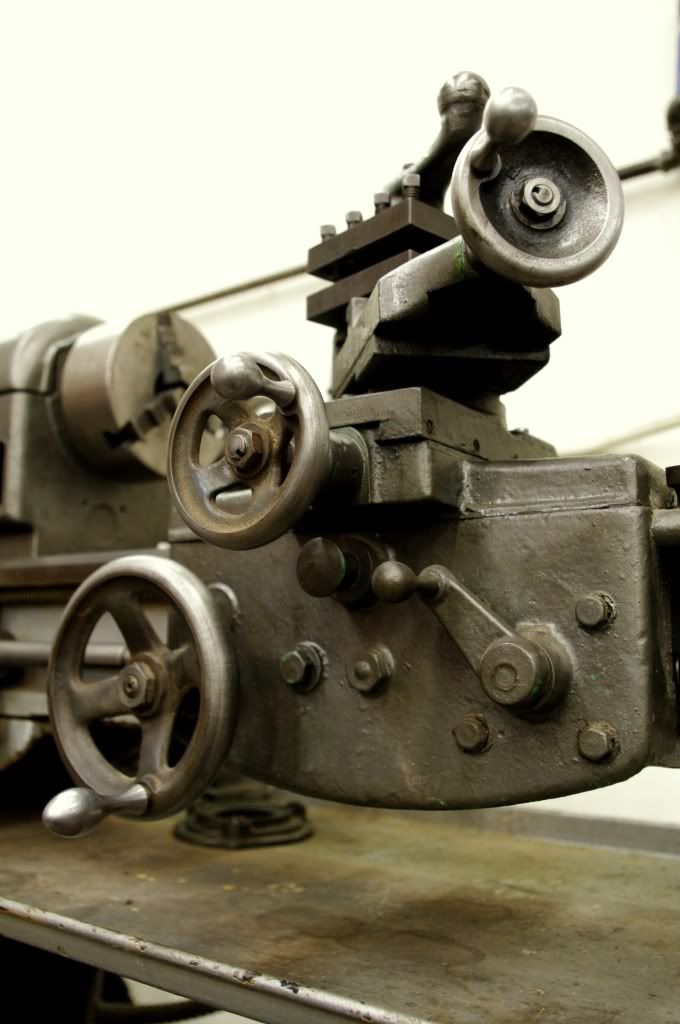

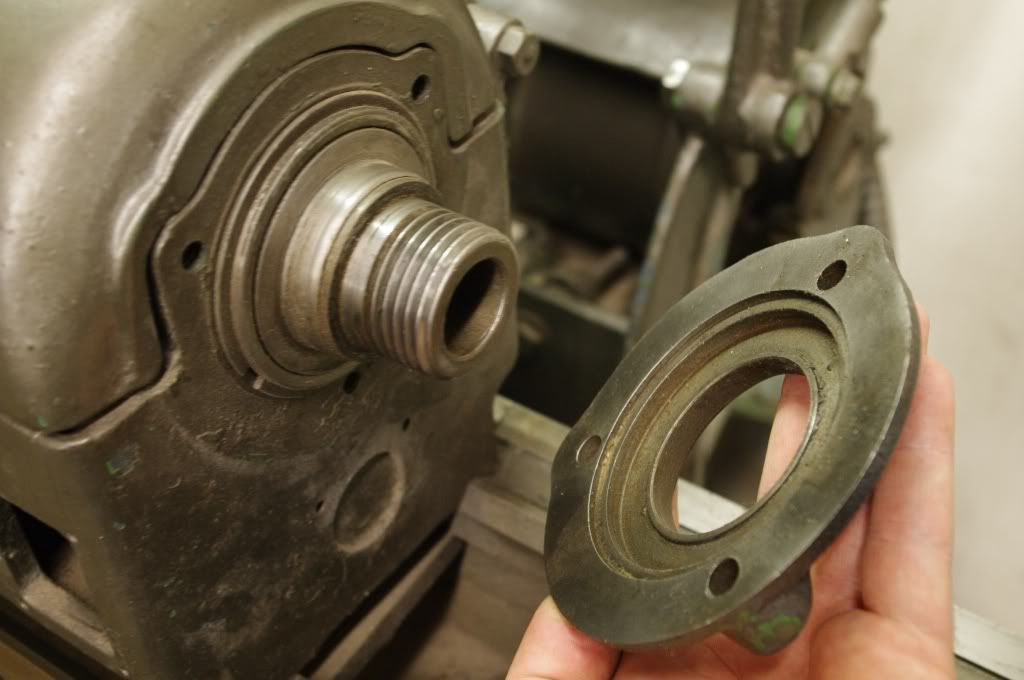

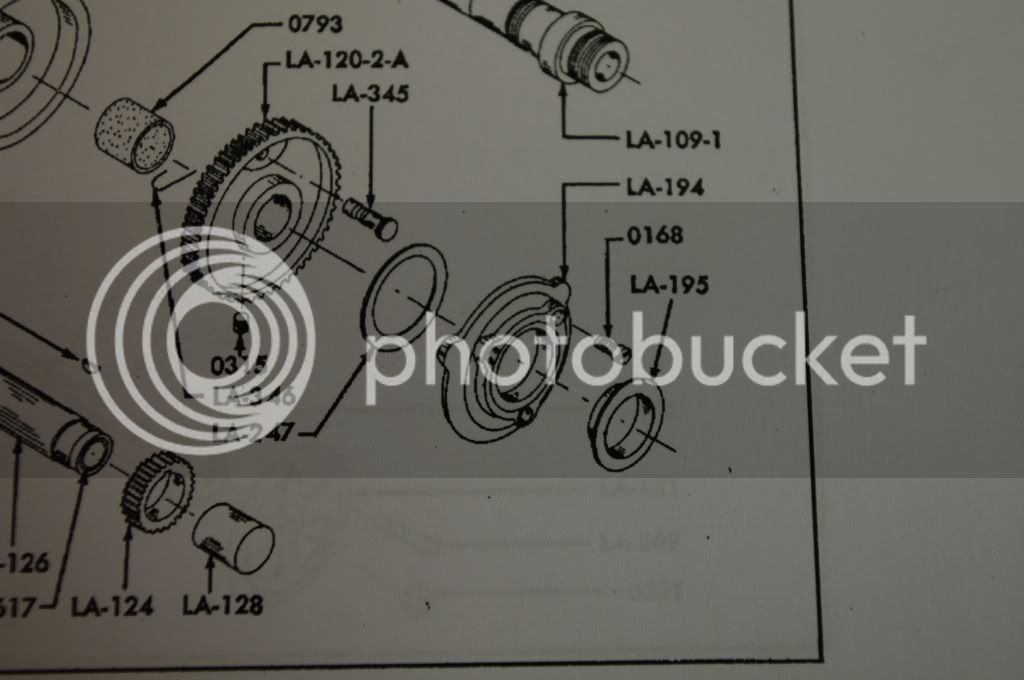

You lathe looks like a Logan model 200 basic lathe that came with change gears (not a quick change box) and without power cross feed. All power longitudinal feed is via the half nuts so there is no gear drive with clutch for power feed.

Once again, join the Logan lathe group and get all the info first hand.

You lathe looks like a Logan model 200 basic lathe that came with change gears (not a quick change box) and without power cross feed. All power longitudinal feed is via the half nuts so there is no gear drive with clutch for power feed.

Once again, join the Logan lathe group and get all the info first hand.