scootermcrad

Active Member

- Joined

- Dec 20, 2010

- Messages

- 35

- Reaction score

- 1

Hello everyone! Great place! I did a little intro, but had some more questions regarding a lathe I just purchased. I was hoping to get some more info.

First off, to be very honest, I've never set up a lathe before. This is new stuff to me. I've only used one, and even that is not saying much. Anyway, I'm trying to change all that....

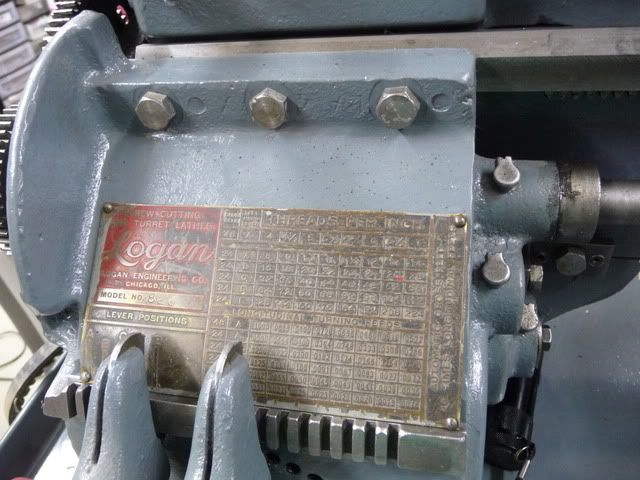

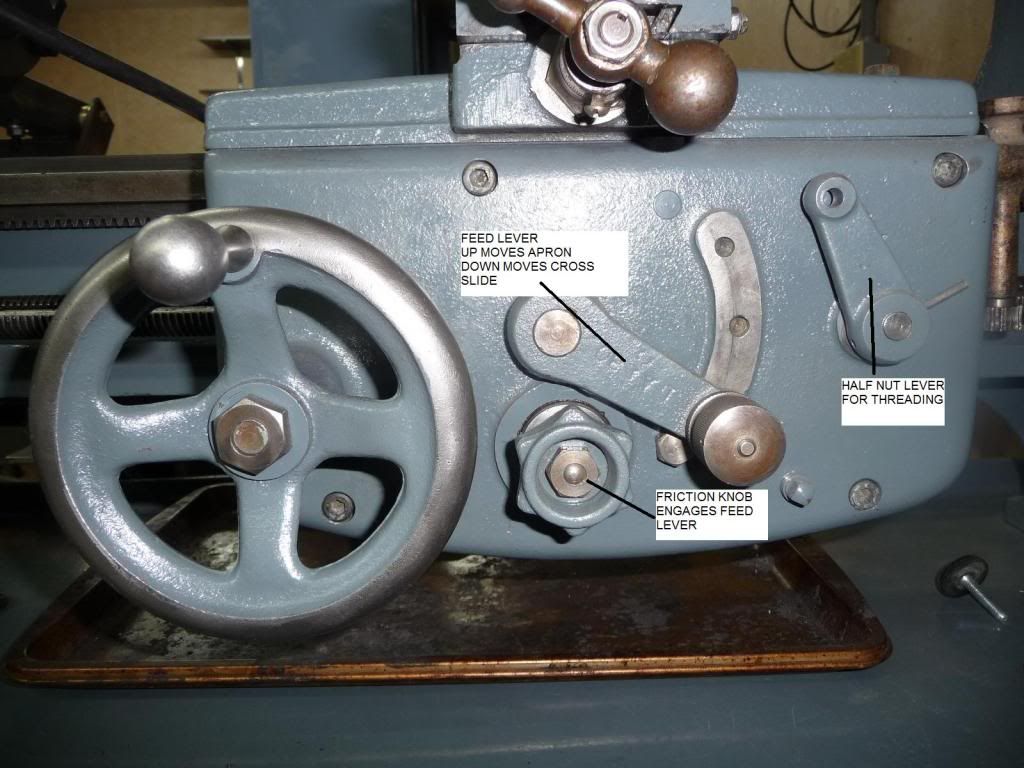

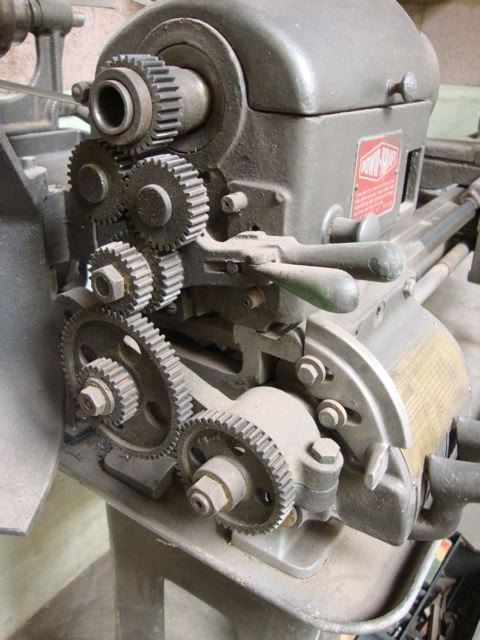

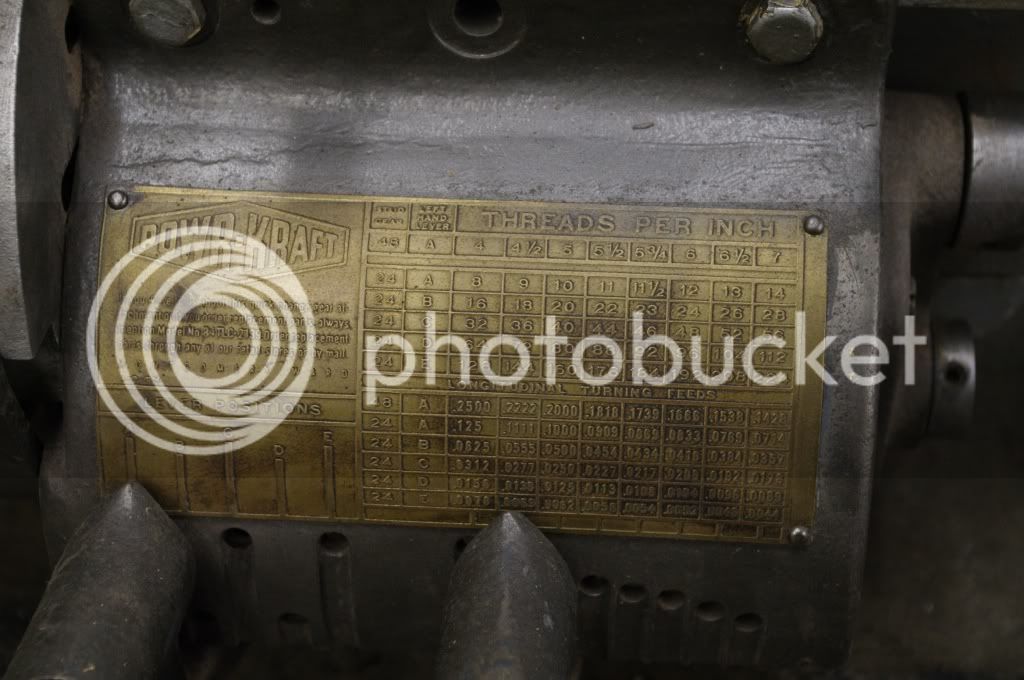

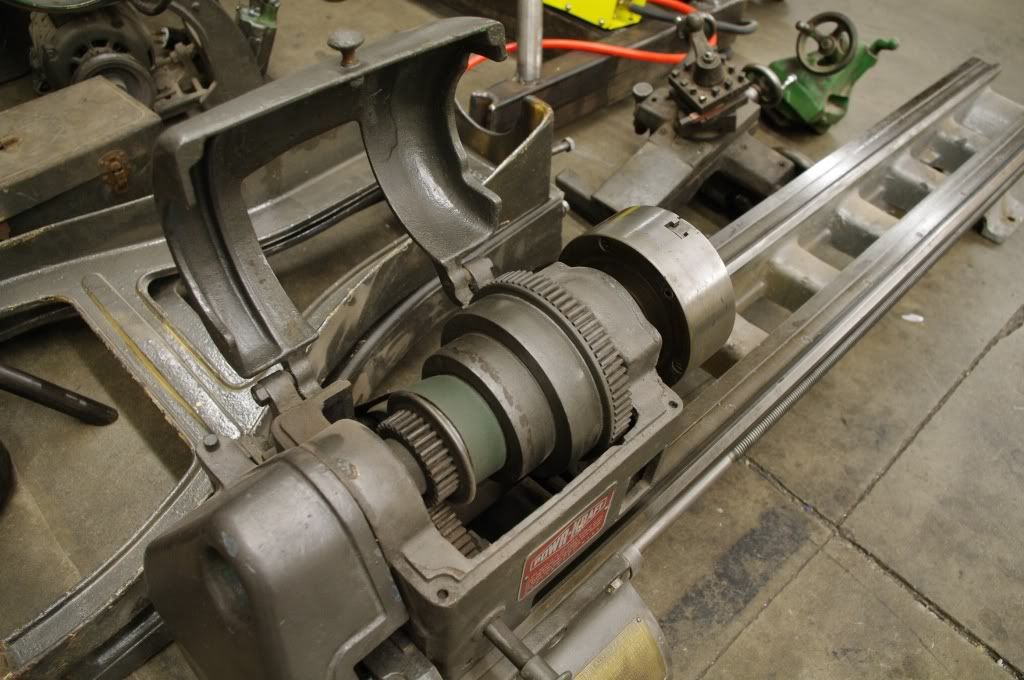

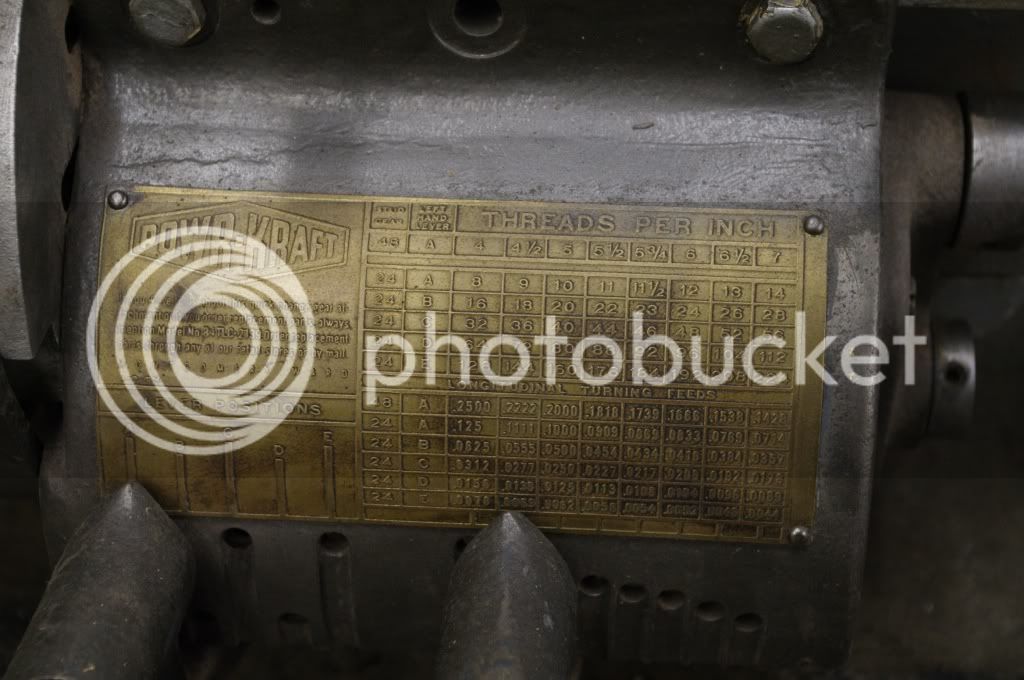

I bought this 10" POWR-KRAFT lathe (84-TLC-2139), which I'm told is essentially a Logan. 50" bed. Appears that it might be the equivalent of a Logan 821. Everything appears to be there to turn a part, but I don't know what a lot of it is. I would also like to clean it up and possibly repaint it before I get it put back together. So maybe someone can give me some recommendations on setup, paint, and maybe just some information about POWR-KRAFT in general.

Super excited to get this thing going! I have a lot to learn! I would appreciate any info you guys could provide!

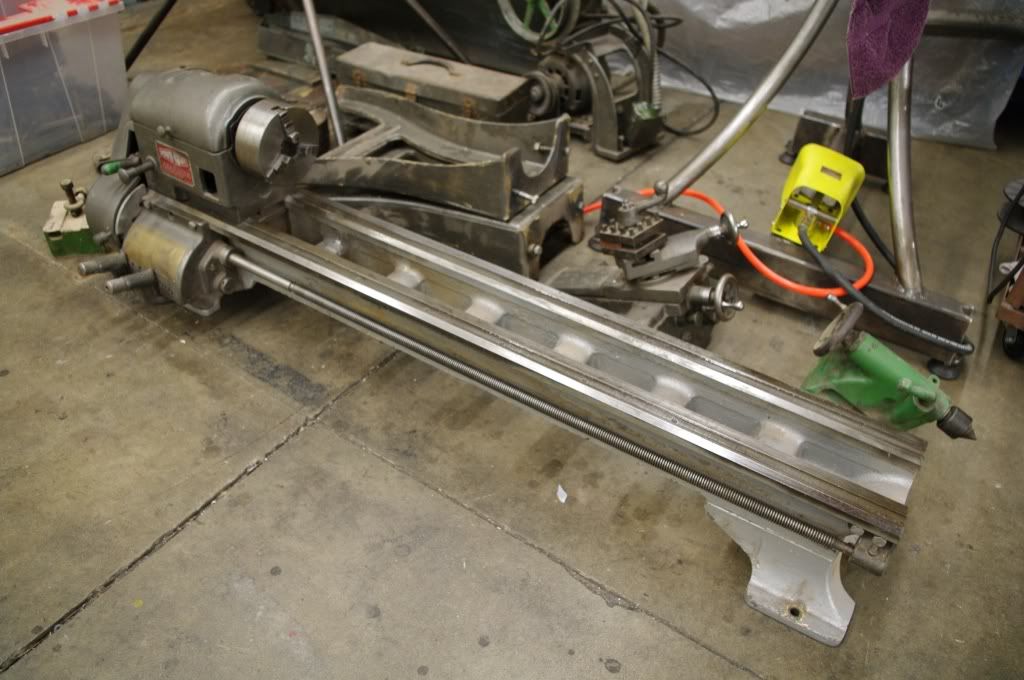

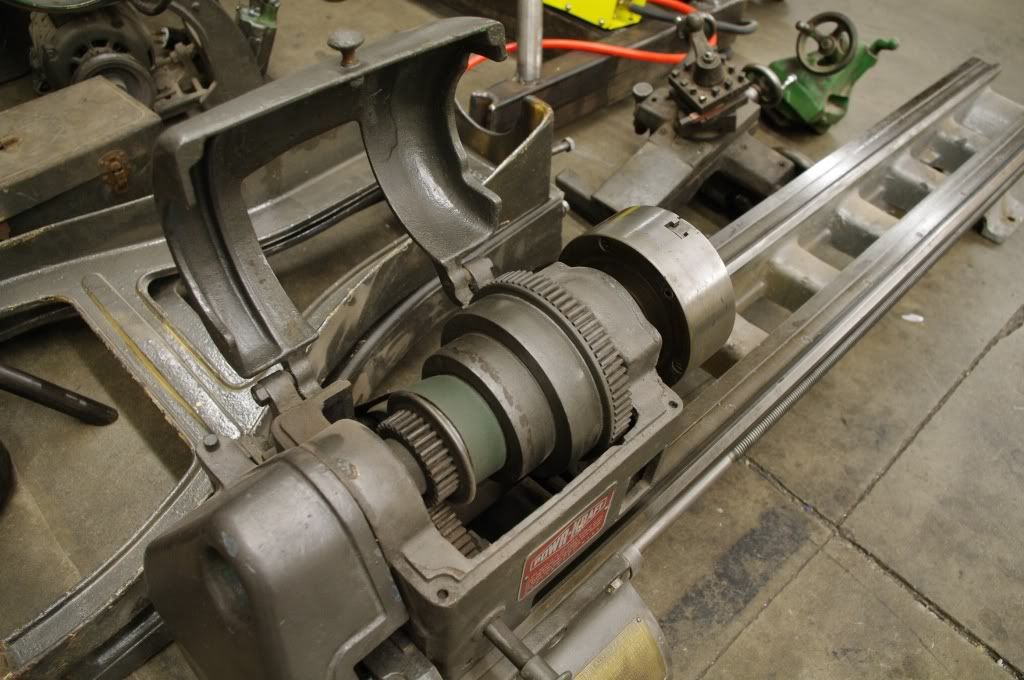

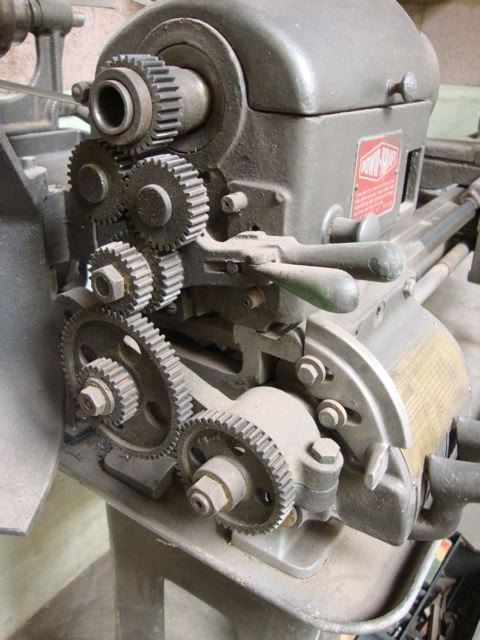

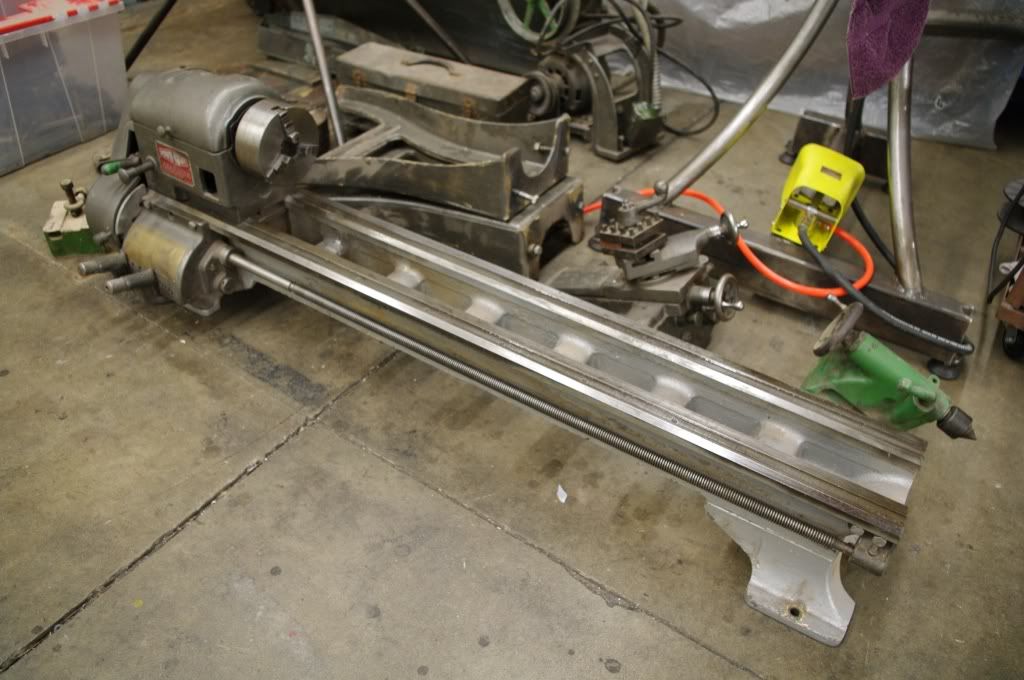

So here it is before it was carefully taken apart to bring to my shop...

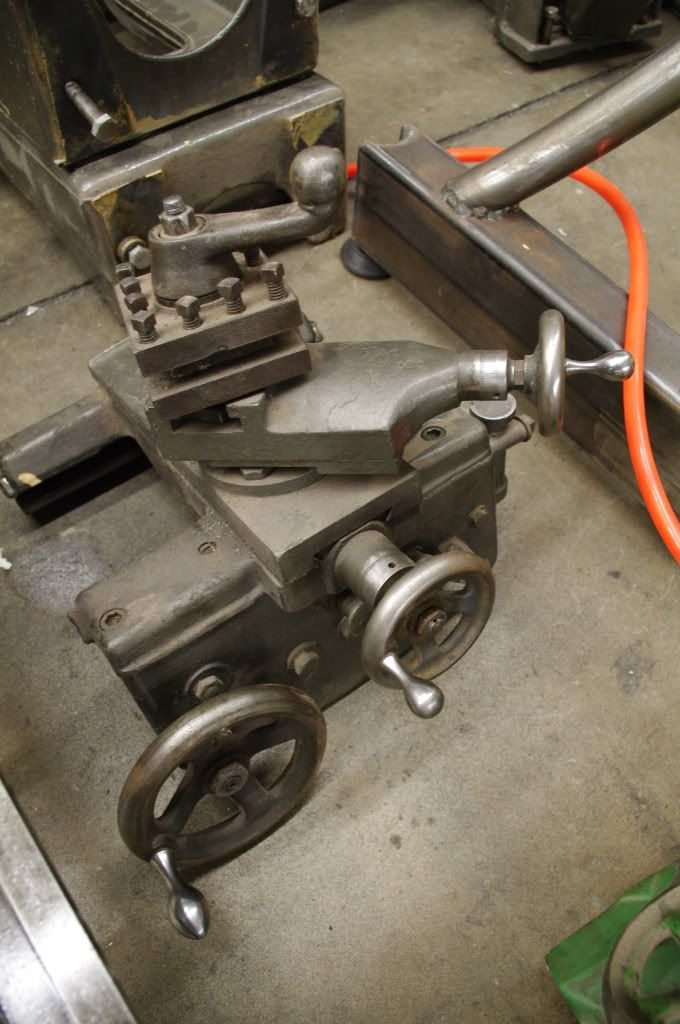

And how it sits, ready for clean up...

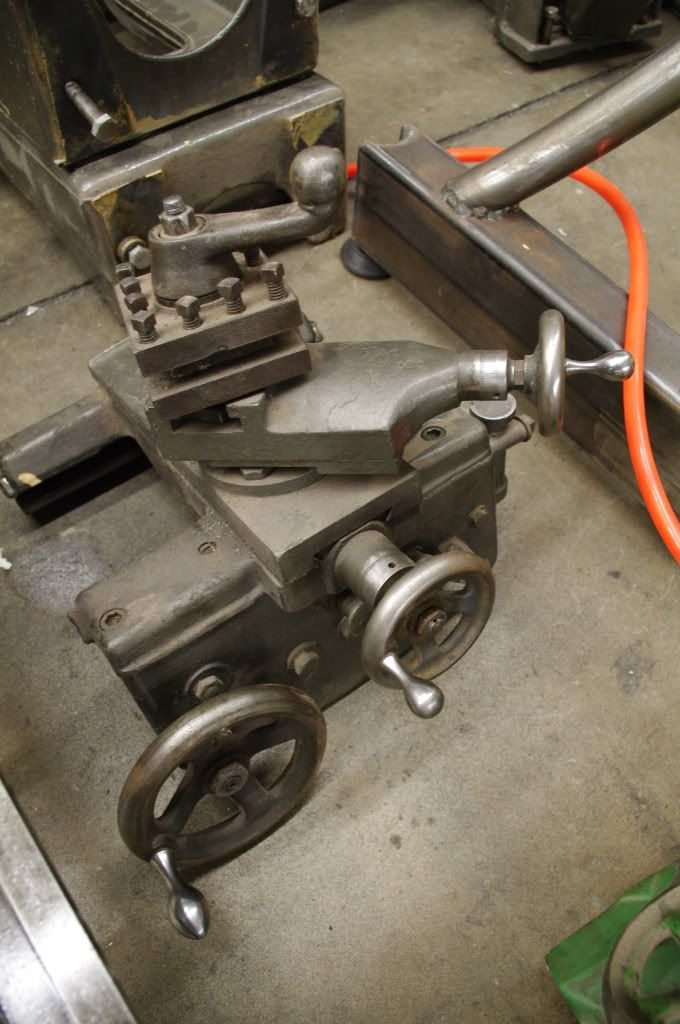

Maybe someone can tell me what these items are. I'm assuming that the green block with the adjuster is a bottom clamp of some kind, but I have no idea.

First off, to be very honest, I've never set up a lathe before. This is new stuff to me. I've only used one, and even that is not saying much. Anyway, I'm trying to change all that....

I bought this 10" POWR-KRAFT lathe (84-TLC-2139), which I'm told is essentially a Logan. 50" bed. Appears that it might be the equivalent of a Logan 821. Everything appears to be there to turn a part, but I don't know what a lot of it is. I would also like to clean it up and possibly repaint it before I get it put back together. So maybe someone can give me some recommendations on setup, paint, and maybe just some information about POWR-KRAFT in general.

Super excited to get this thing going! I have a lot to learn! I would appreciate any info you guys could provide!

So here it is before it was carefully taken apart to bring to my shop...

And how it sits, ready for clean up...

Maybe someone can tell me what these items are. I'm assuming that the green block with the adjuster is a bottom clamp of some kind, but I have no idea.