- Joined

- Jan 17, 2009

- Messages

- 887

- Reaction score

- 81

The valve rod support, I drew it up fancy and didn't think to much on how to make it, but when it came to it, I realized it was quite an awkward shape, I could have redesigned it, but I kind of liked it as is was. The important part is for the hole to be on the same centre height at the valve rod, so decided it would be easier to make it in two bits and bring it to the correct height by adjusting the base thickness.

With a bit of 10mm brass bar first turned a little 4mm dia chucking piece on the end, then over on the mill drill the hole for the valve stem and mill the flats.

Cut it off to length and centre drill and tap the other end M3, then gripping on the chucking piece, turn the tapered bit.

Sorry pic not very good.

Cut the chucking bit off, and make the base adjusting its thickness to get the correct centre height for the hole.

These are the bits.

I'll whittle that square end sticking up into a round later.

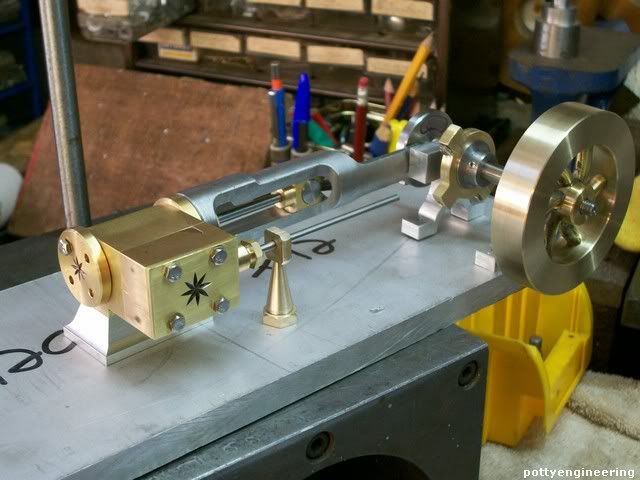

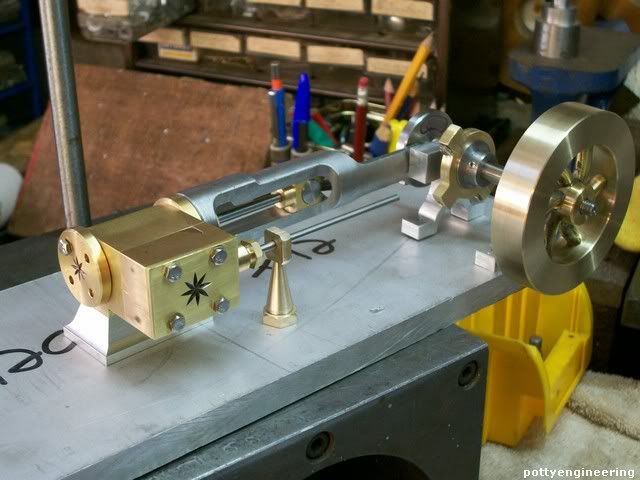

And how its looks.

Just got the base to machine up, but before I'll do that I want to get all the bit loosely fitting together so I can get the positioning correct.

Stew

With a bit of 10mm brass bar first turned a little 4mm dia chucking piece on the end, then over on the mill drill the hole for the valve stem and mill the flats.

Cut it off to length and centre drill and tap the other end M3, then gripping on the chucking piece, turn the tapered bit.

Sorry pic not very good.

Cut the chucking bit off, and make the base adjusting its thickness to get the correct centre height for the hole.

These are the bits.

I'll whittle that square end sticking up into a round later.

And how its looks.

Just got the base to machine up, but before I'll do that I want to get all the bit loosely fitting together so I can get the positioning correct.

Stew