Cogsy

Well-Known Member

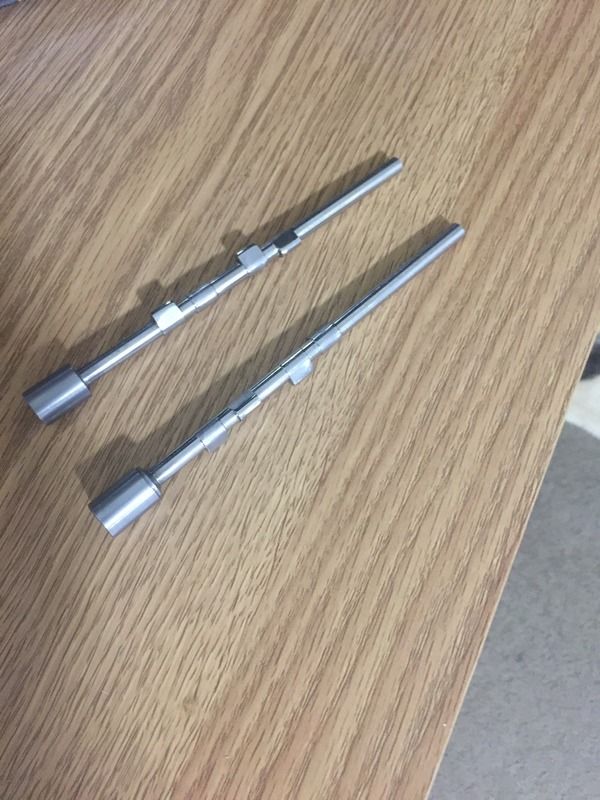

Pipes look good. What did you use to bend them and are they the cheap SS drinking straws off eBay? (I'm hoping so cos I've got a heap of them in stock for the same purpose - just hoping they work).

Parksy,

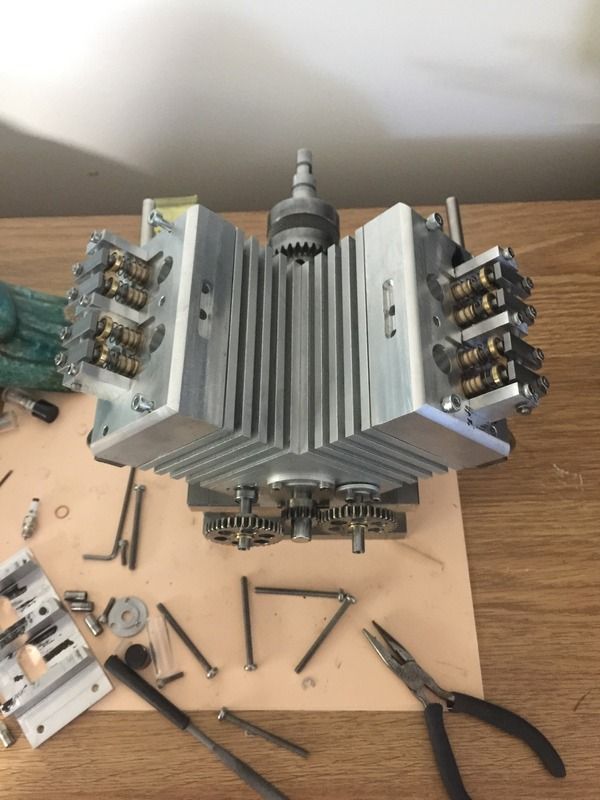

I may be in the midst of a senior moment, but don't your two cams need to be machined as mirror images to one another since they rotate in opposite directions? - Terry

Enter your email address to join: