- Joined

- Dec 9, 2015

- Messages

- 327

- Reaction score

- 349

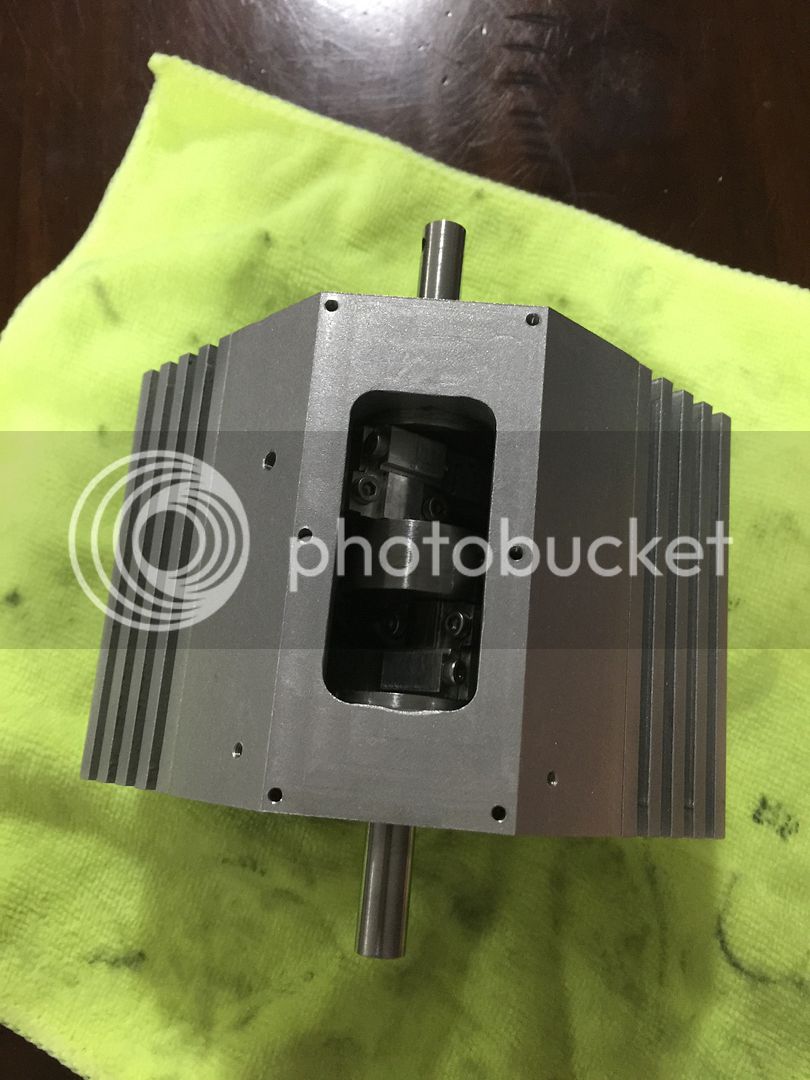

Gday Brian, thanks for the suggestion. This is something that I've been thinking about. I've thought about using clear tube as a sight gauge as it gives me a chance to monitor the level. But then it's not something I'm 100% on at this stage.