- Joined

- Dec 9, 2015

- Messages

- 327

- Reaction score

- 349

Hi all

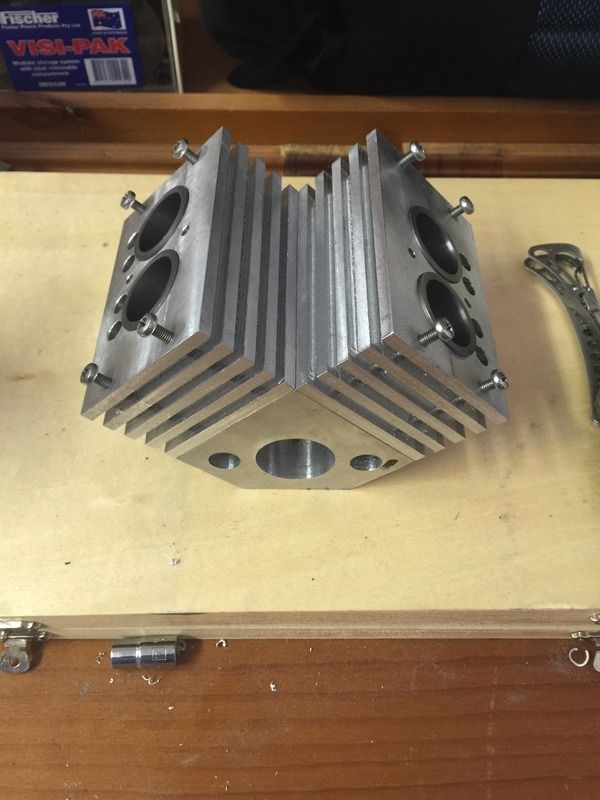

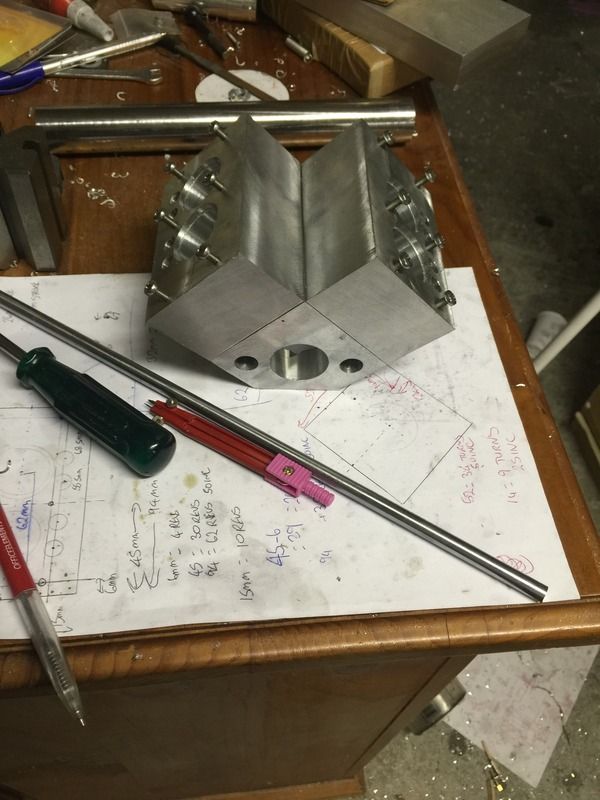

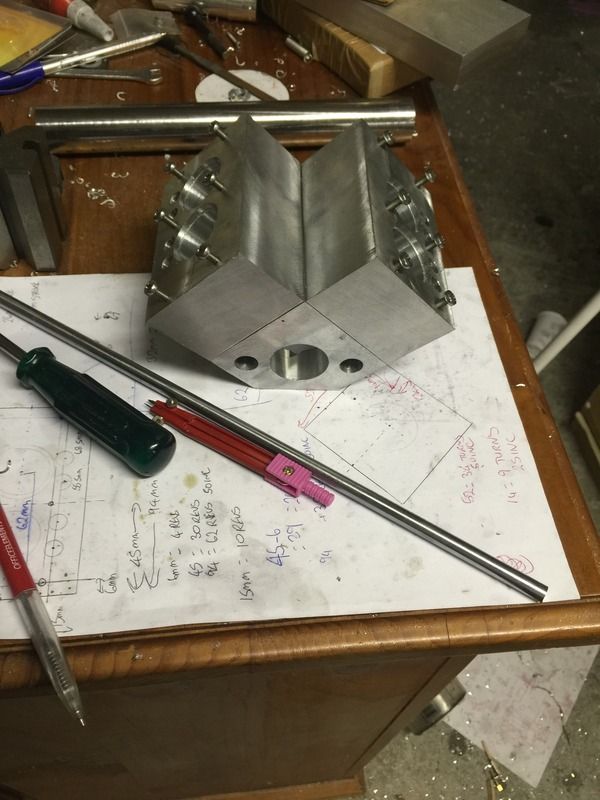

I've started another project, this one being a v4. There aren't any plans as I'm designing it on the fly as I did with my last engine.

So far I've drilled and bored the crankshaft/camshaft tunnels and cylinder bores. The cylinder bores will be sleeved with cast iron liners.

I've just (almost) completed the crankshaft which is one piece 4140. Usually I find eccentric turning on the lathe to be a stressful event(especially on the mini lathe) but this time round everything just worked smoothly.

I haven't made provisions for a bearing in the centre of the crankshaft, I plan on running two large ball bearings on the outside and the fact that it is a single piece of 4140 thought it would be plenty strong enough.

Anyway, here are some progress pics.

Cheers and thanks for viewing

Andy

I've started another project, this one being a v4. There aren't any plans as I'm designing it on the fly as I did with my last engine.

So far I've drilled and bored the crankshaft/camshaft tunnels and cylinder bores. The cylinder bores will be sleeved with cast iron liners.

I've just (almost) completed the crankshaft which is one piece 4140. Usually I find eccentric turning on the lathe to be a stressful event(especially on the mini lathe) but this time round everything just worked smoothly.

I haven't made provisions for a bearing in the centre of the crankshaft, I plan on running two large ball bearings on the outside and the fact that it is a single piece of 4140 thought it would be plenty strong enough.

Anyway, here are some progress pics.

Cheers and thanks for viewing

Andy