I put the Chuck Fellows carb back on (I lied about the needle---had it confused with the George Britnell carb clone that I built--The Fellows carb does have a nice tapered needle.) I monkeyed with the ignition timing and got a couple of good sustained runs. I could have ran and got the video camera, but the sun is down now and there isn't that much light out in my main garage. My timing gears are making a terrible racket--sounds like somebody torturing a duck!!! I may have to put a mark on the cam shaft and the ignition cam to be able to re-set them to this setting, and pull the gear cover off to see what in heck is going on with the gears. I never had gears make a racket like that before, but I have never used a jockey gear between the crank and cam gear before, so I expect it may have something to do with that. Since I have to pull the gear cover, I will set up a degree wheel and a pointer and check the valve timing while I have things apart.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

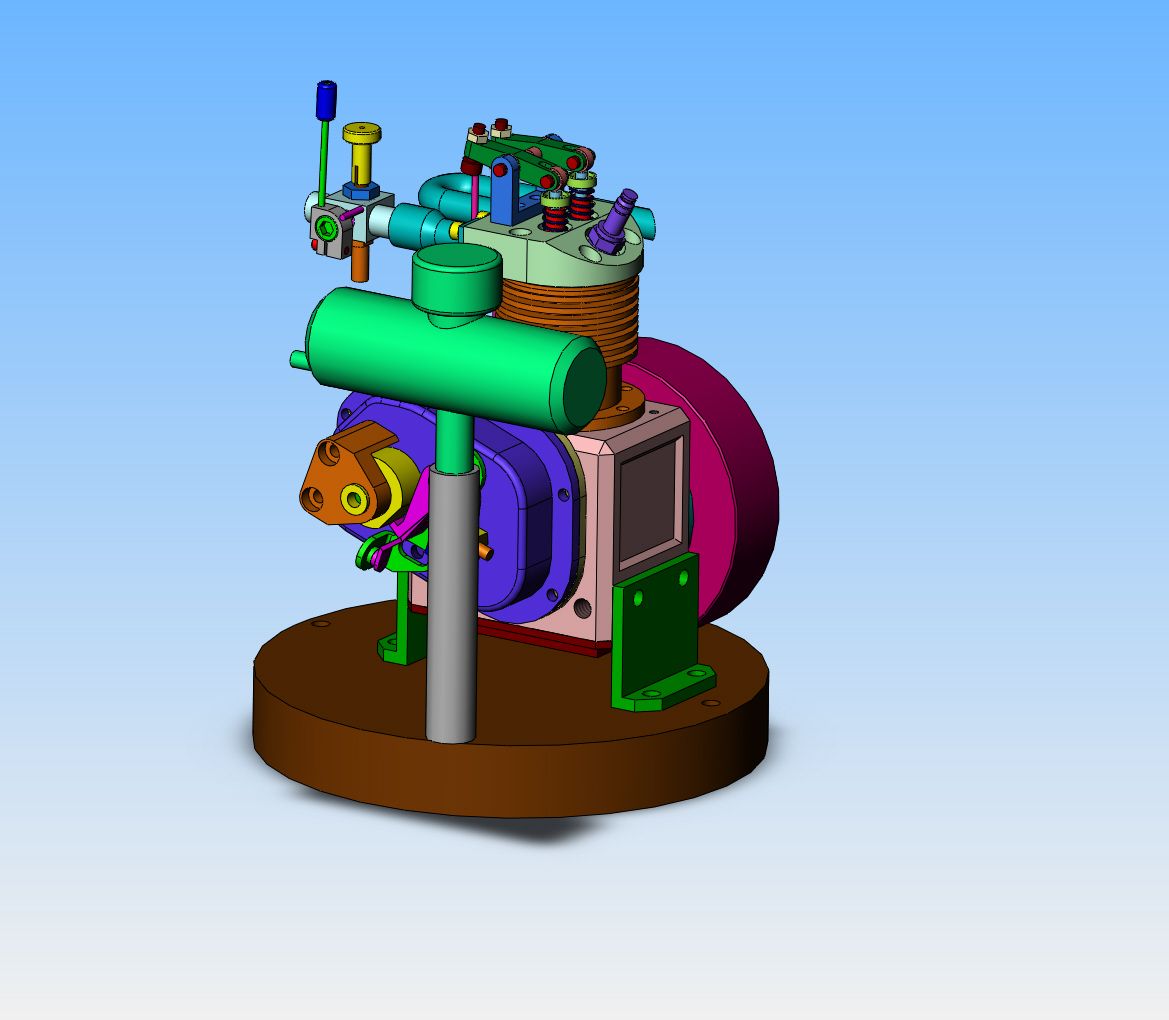

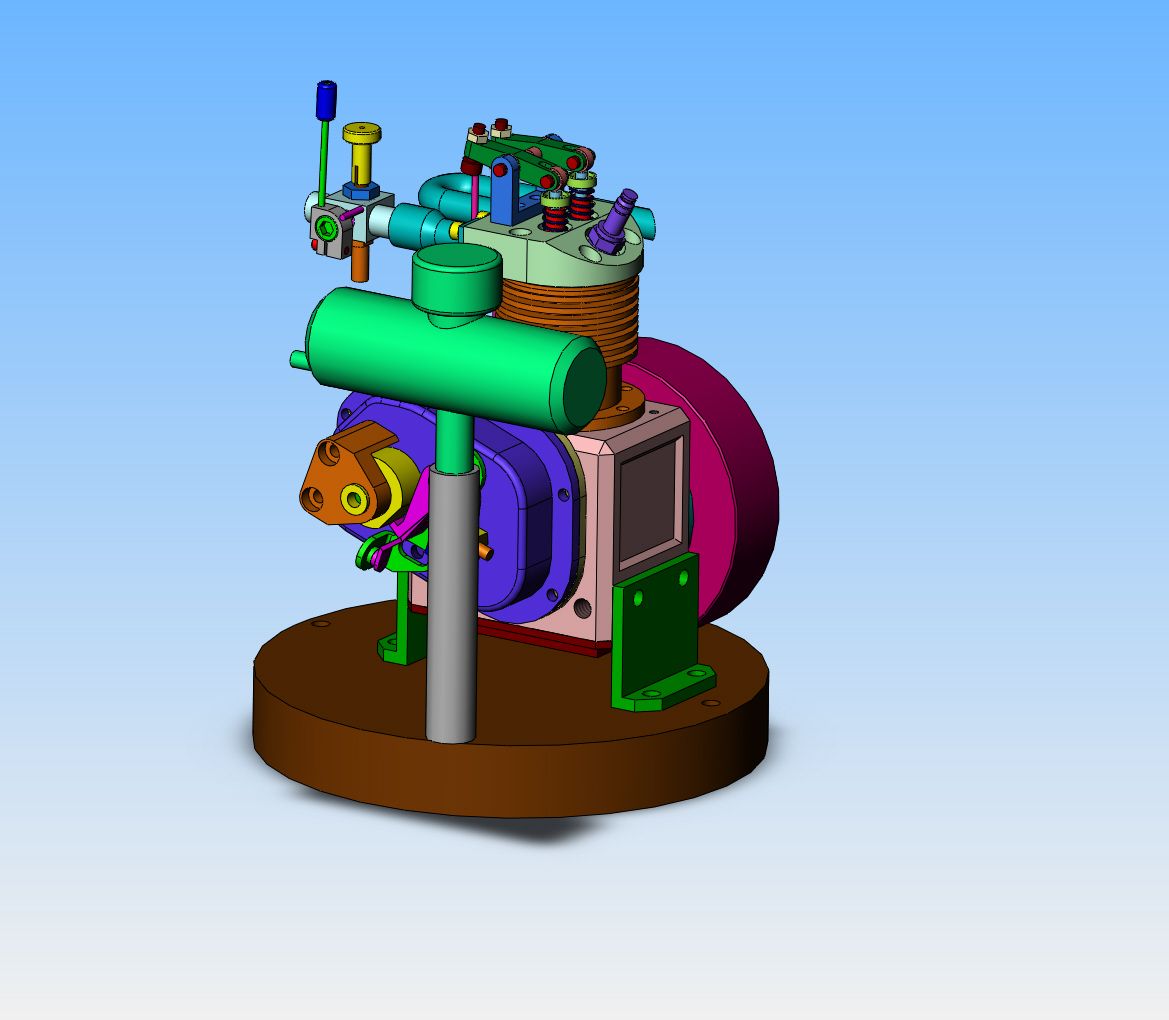

Nemett Jaguar--Canadian style

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

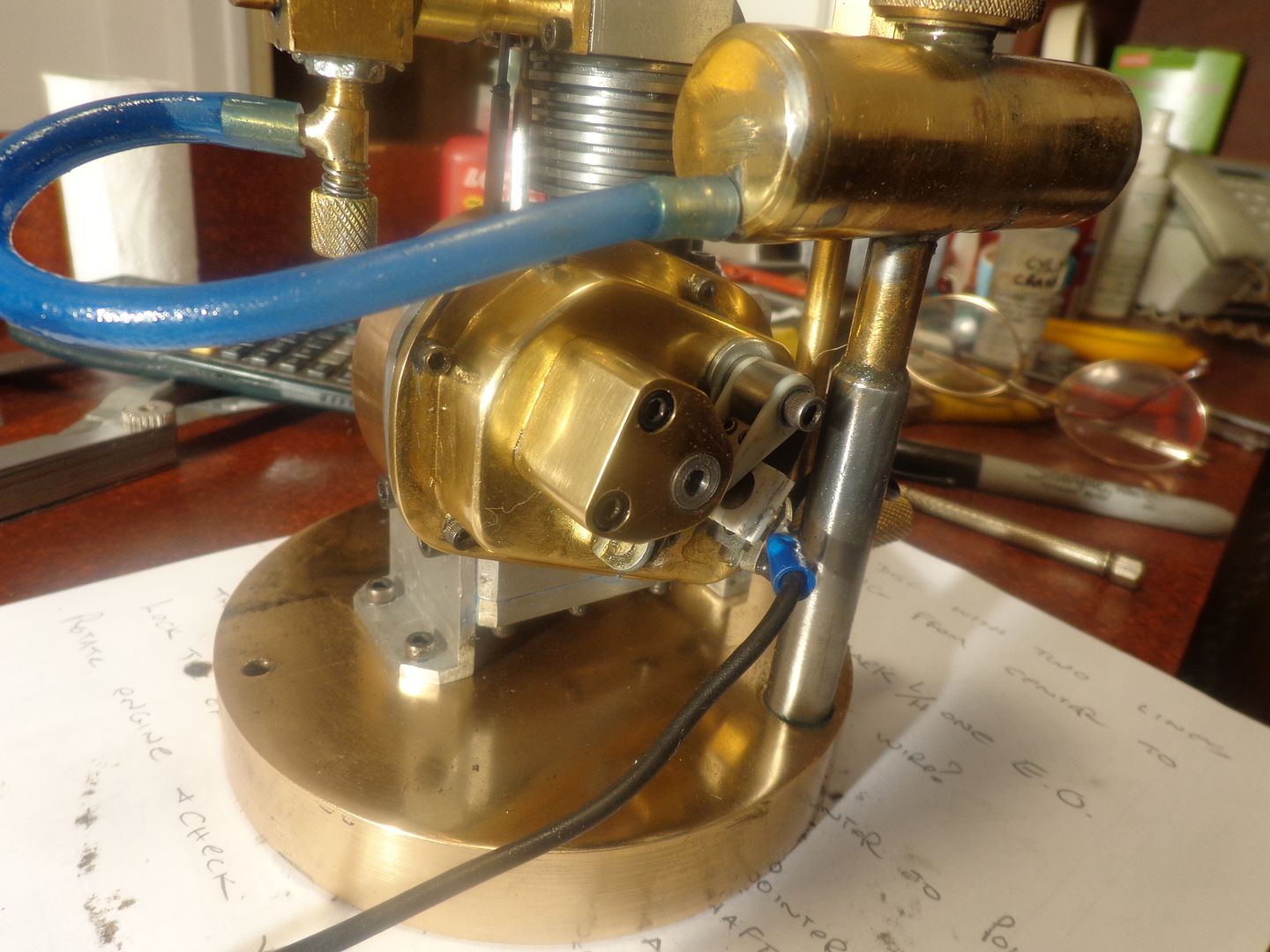

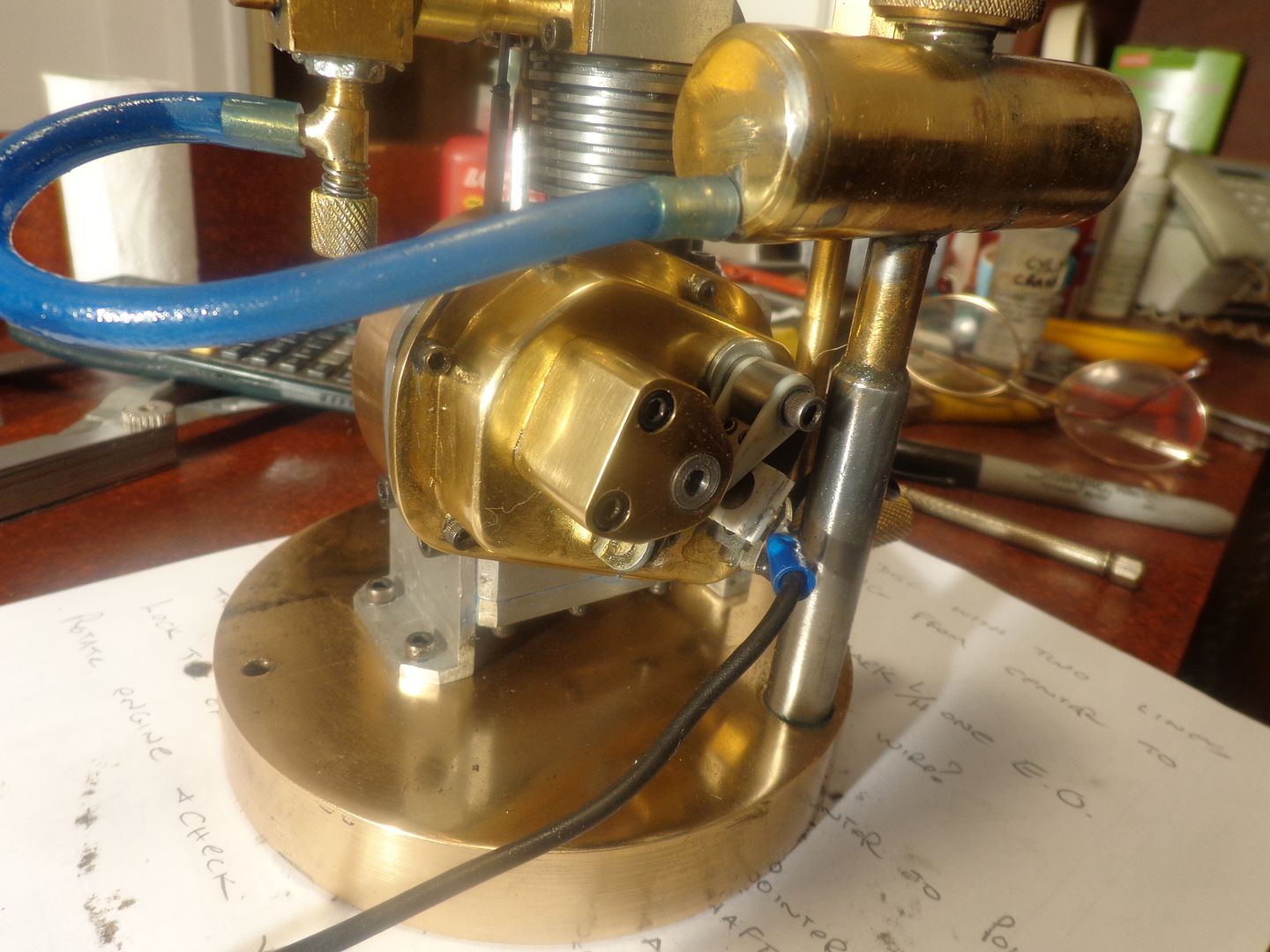

Back to work on the engine this morning. I have dismounted it from the bronze sub base and brought it back into the office/machine shop. The engine has developed amazing compression after all the short runs it had yesterday. I pulled the gear cover off to see why my timing gears are squawking like ruptured ducks, but there is no reason immediately visible. I may take the cowards way out and coat them with 600 grit lapping paste and run them for 25 minutes to see if it quiets them down any.--That has worked for me before.The jockey gear floats on its pinion--it is supposed to. However it also has a certain amount of "float" longitudinally as well. I may see about some form of spacer to prevent that axial movement. I am going to have to do some studying on this degree wheel business as outlined by Malcolm Stride to set the valve timing. I don't fully understand it, as I have always set the gear timing "by eye".

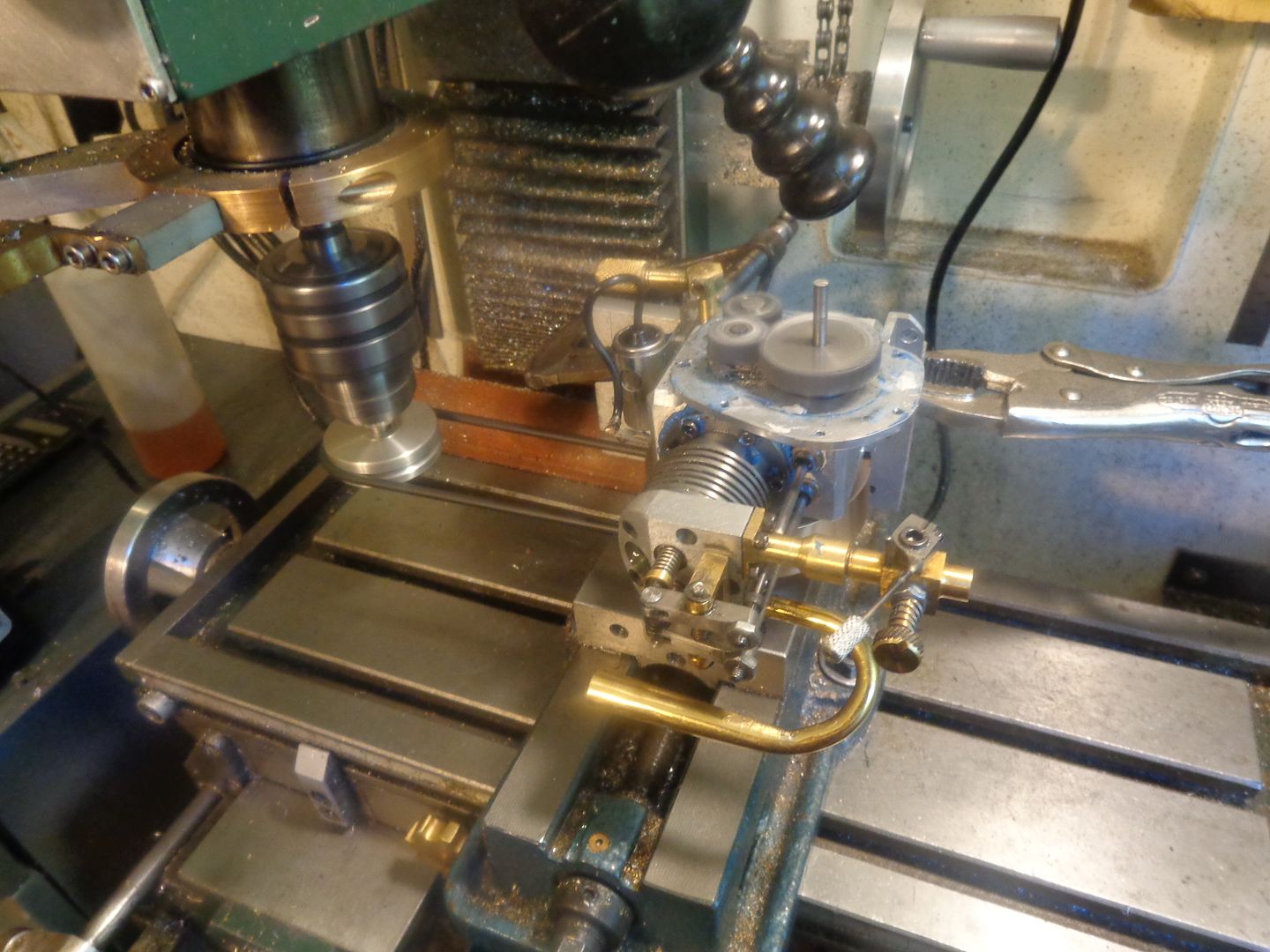

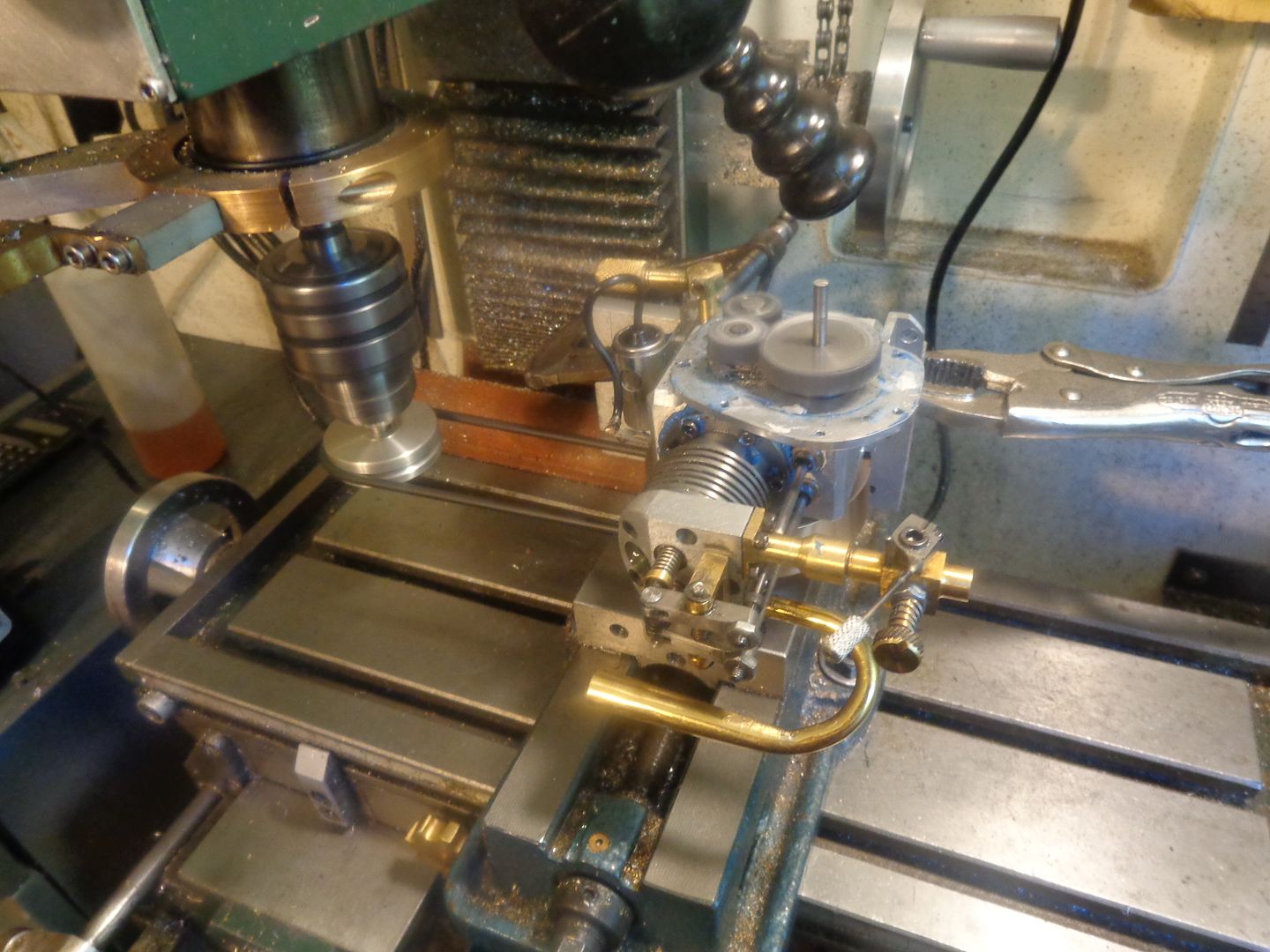

This is a quick pic of "running in" the spur gears with some 600 grit lapping paste on the teeth of the gears. The black o-ring drive belt is driving the engine crankshaft via the mill quill mounted pulley. I will let it run for about half an hour like this, and hopefully get the noise out of my gears.

I had expected that the lubricating oil from the sump would find its way out into the gearcase to lubricate the gears. Not so---When I pulled the gear cover off, those gears were dry as a bone. I will pack the gearcase with grease before I reassemble things.

It only took about 10 minutes of running until all the squawk was gone from the gears. However, I have developed a theory as I have been doing this. The ignition cam and the cam gear are both cantilevered out bast the support bearing on that side, with the ignition cam being farthest out. The spring in the ignition points is very strong, and the shaft which is only 4 mm diameter may be deflecting when the cam has to compress the spring which holds the points shut, to open them. If so, the shaft could be deflecting, which would change the mesh of the large cam gear and create the noise. I may have to put an outboard bearing on the gear cover to prevent the shaft deflection---Don't know yet!!!

HAPPY DAYS ARE HERE AGAIN---YES!!!! We have a runner. I tried every trick I know of with both the Chuck Fellows carb and the model airplane carb and no joy!!!--Then I switched over to my George Britnell Clone carb and almost immediately had a runner. This engine has been a real oinker to get running, but I feel much better about the world right now!!!---Brian

Swifty

Well-Known Member

Very nice Brian, now you can think about your next project

Paul.

Paul.

- Joined

- Jun 24, 2010

- Messages

- 2,361

- Reaction score

- 931

..with both the Chuck Fellows carb and the model airplane carb and no joy!!!--Then I switched over to my George Britnell Clone carb and almost immediately had a runner.

Congrats, purring like a kitten. So what's the moral of the story? Are all 3 carbs similarly sized or George carb is the sweet spot? Or different venturi shape/action? Or relative positioning? Mixture control? etc etc

There is no logical reason for it to run on one carburetor and not the others. All three of those carbs are interchangeable on my other internal combustion engines, and they all work equally well. There are other things at work here that I don't fully understand yet. This morning the engine had incredible compression. After that one good run where I took the video, it wouldn't start and I had no compression. Obviously something has changed, but I'm not sure what, and I haven't felt like playing with it this afternoon. I don't think anything is terribly wrong, but there are some transients at work here that I have to figure out, and it should run on any of the carburetors.----Brian

We had both grand-daughters sleep over last night, as today we have tickets for the live theater version of Peter Pan. I am up early, just beginning a run of diagnostics on the engine. First though, I thought a couple of updates were in order. The running in of the gears with 600 grit compound, as outlined earlier has silenced them completely--no more "stepped on duck" noises from the engine as it rotates. The gearcase was filled with grease, as none of the sump oil was making it out to lubricate the gears. I may have gotten a bit too exuberant with the amount of grease I packed in, because for the first few runs I had grease oozing out around the camshaft where it exits the gearcase, as there is no seal there. I was concerned about deflection of the end of the camshaft, because the spring in the ignition points is quite powerful, and the ignition cam is cantilevered a long ways out past the bearing. I solved that issue by making a new ignition cam with an extended 5/16" (about 8mm) shoulder on it, and made a new brass bearing to capture and support it which bolts to the outside of the gearcase. This has completely solved the deflection problem. The deflection problem may also have been part of the reason for my squawky gears, I'm not certain. I am now about to pull the cylinder and head off and try to figure out where my compression has gone to.

After a quick disassembly and check, there doesn't seem to be any leakage at the valves, as I had feared. The o-ring may have been worn a bit, because, as you remember, I had cross hatched the inside of the cylinder with my brake hone in preparation for the cast iron valves. This will wear the outside of a Viton o-ring away very quickly until the cross hatching on the cylinder wall is polished out by the action of the ring rubbing on it. I seem to have restored my compression enough to get a "bounce back" when I give the flywheel a flip by hand, so I may (cross my fingers) have solved the problem. I might get a chance to find out later today.

- Joined

- Mar 1, 2010

- Messages

- 865

- Reaction score

- 82

Great job in getting it to run but Deja Vu !! Your starting, carb and compression problems just about exactly reflect my experience with both engines (Bobcat and Lynx). You experience with other engines helped you to work through it but I was a first timer so went down a fe blind alleys and loops before I got mine running. Unfortunately I'm unable to view the video as I'm running Firefox and the No script add-on. After allowing links to 20+ other sites from the Photobucket site to the point I get a "do you really want to do this" message so I can't get the video to run. (have you put it in YouTube?) What does it rev like? Any idea about the max RPM you've achieved? Pete (And for some reason running Firefox on Linux removes all the CR/LF's from the text)

Last edited:

Doubletop--Here is the link to the same video on Youtube. Note the vapour shooting out the intake barrel of the carburetor. I think that the valve timing is a bit too radical for a single cylinder engine, but I'm not really sure. My intake valve is not leaking, and the lash is set correctly. Does your engione do that?---Brian

[ame]https://www.youtube.com/watch?v=6VBaEu9Ivdo&feature=youtu.be[/ame]

[ame]https://www.youtube.com/watch?v=6VBaEu9Ivdo&feature=youtu.be[/ame]

Last edited:

Has anyone ever seen this engine built to its original Jaguar single cylinder configuration? I have searched the internet trying to find a video of it, and I can not find one. It seems that many people have successfully built the two cylinder Bobcat version, but I couldn't find a single thing about the Jaguar configuration. Then again, it could be that I just have poor Google-Foo. If you know of a link to one, please post it. I would love to see one.---Brian

- Joined

- May 27, 2010

- Messages

- 2,999

- Reaction score

- 1,171

Congrats.You have a runner. As I said after a hard day of trying to get and obstinate engine to start n run and it just won't budge.

Come back next day and she sprints away off .The fun would be get her to run at sustained idling speed.

We share you pain and joy of engine building.

OK .Maestro.What's next on the line???

Come back next day and she sprints away off .The fun would be get her to run at sustained idling speed.

We share you pain and joy of engine building.

OK .Maestro.What's next on the line???

- Joined

- Mar 1, 2010

- Messages

- 865

- Reaction score

- 82

Brian Thanks for posting the Youtube video. It sounds to be a great runner but like mine very particular about the throttle control. There is no slamming it open and shut as it will just give up trying to keep up. Min revs I achieved on the Lynx was about 800 and max 5000. I was hoping it would get to 8000 but nowhere near it. That was with electronic ignition that auto advanced to about 30deg BTDC. Of course your advance is static, what do you have it set to? Pete

Pete--my ignition is set to about 10 degrees advance. Again, I ask you--do you have vapour shooting out of your carb air inlet like mine does when you watch the video?

I have one trick left. If it doesn't work, I am out of ideas. I will remove the inlet valve rocker arm and pushrod and put a lighter spring on the valve---let it become in effect an atmospheric valve. If that doesn't work, this may become my first model to go "On the shelf" and be an ornament rather than a running engine.

johnny1320

Middle aged Member

- Joined

- May 15, 2013

- Messages

- 149

- Reaction score

- 16

I if your getting vapor then your intake valve is closing too late or you could have too much valve overlap, also try it with the exhaust pipe removed, exhaust may be too restrictive. Engine looks great Brian!

Similar threads

- Replies

- 0

- Views

- 2K