You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nemett Jaguar--Canadian style

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Trust me, my friends, when I say it has been a Hmmmm---Hectic afternoon. I lay down for a nap early this afternoon, but instead of napping, I found I was laying there going over every possible thing I have ever learned or known about small engines. First and most important rule---Assume nothing!!! I found Malcolm Stride's explanation of setting the valve timing very confusing. That could be my problem, not Malcolm's. I came back down to my office and fired up the computer, and arranged the 3D model so that the piston was at 40 degrees before bottom dead center, going in the direction of rotation. This looked nothing like I had initially set things up, so I took the gear cover off and re-timed the gears to agree with what my solid model had shown me. For a while I had removed the pushrod and rocker from the intake valve and put a much lighter spring on, trying to run it as an atmospheric valve. This did work to some extent, but I found that with the lighter spring, the valve didn't close consistently, so I put the strong spring, rocker arm, and pushrod back into the intake side. I want to believe that somewhere, somebody, must successfuly run engines without a head gasket. I have never had that work for me, so I made a very small ring of gasket material that would fit between the cylinder head and the ring around the top of the cylinder body. This increased the come and go compression by a quantum amount. While I had the head off to add the gasket, I remembered some of the problems I had with the Rupnow hit and miss engine caused by too much material in the cylinder head shrouding the tip of the sparkplug, so I set the head up in my mill vice and relieved a bit of the material around the tip of the sparkplug. I noticed that the gas cap on the tank I had "borrowed" from my Webster didn't have a vent hole in it, and I have learned from experience that just loosening the cap doesn't always work, so I drilled a .039" vent hole in the cap. After reassembling everything (except the exhaust system), I gave it a try, and was immediately rewarded by what you see in the video. the engine ran for about 4 minutes, then the damn set screws which lock the big gear to the camshaft came loose, and it quit again. I am beginning to realize that I HATE these small totally enclosed engines. Every time a set screw comes loose, you have to take the entire friggin' engine apart to tighten them back up!!! Next time I will double set screw everything, with two setscrews to lock the gear to the shaft and two more behind them to lock the first set of set screws. At any rate, here is my second sustained run, and if something utterly dreadful hasn't happened to my camshaft, I think I am going to get this thing whipped!!!

Here is the same video, only this time on Youtube.

[ame]https://www.youtube.com/watch?v=AGzhtfaowk4&feature=youtu.be[/ame]

[ame]https://www.youtube.com/watch?v=AGzhtfaowk4&feature=youtu.be[/ame]

- Joined

- Mar 1, 2010

- Messages

- 865

- Reaction score

- 82

Pete--my ignition is set to about 10 degrees advance. Again, I ask you--do you have vapour shooting out of your carb air inlet like mine does when you watch the video?

Brian

Apologies: I did get vapour out of the intake but don't now. I had a valve that didn't close fully at the point of firing. As you are getting good compression I'd suggest that you check the valve clearance at the firing point.

But you'd know that?

Pete

Last edited:

Okay people--I think we are done like dinner. After disassembling the engine one more time, tightening up all the miserable set screws that kept backing off and putting a second set of "locking" set screws behind them, the engine seems to be running quite fine. It is VERY touchy about changing speeds, and is as liable to stall as it is to change to a faster or slower speed, but I think that is just a matter of carburetor setting and ignition timing . I still get the vapor out of the carburetor, but that may just be the nature of this engine. If it is caused by valve timing, it won't go away. If it caused by a bit of leakage at the intake valve, it may go away on its own. This has been a hard won battle, and I think a lot of the problem was created by myself misinterpreting the valve timing instructions.--On any video's of I have seen of the twin cylinder version of this engine, I think I see blowback coming out of the carburetors on them also---of course if they are running the propeller, the airstream hides the blow-back from the carb and you don't see it. This has been a quick/fun/frustrating build, but at the end of it we have another runner to add to my stable of i.c. engines. This makes number seven. I will be publishing a link to the drawing package sometime in the coming week.-----Brian rupnow

[ame]https://www.youtube.com/watch?v=IT00-T0crEI&feature=youtu.be[/ame]

[ame]https://www.youtube.com/watch?v=IT00-T0crEI&feature=youtu.be[/ame]

Last edited:

Thank you guys, for the nice comments. Things generally always get a little crazy for me at the end of a build.This one scared me a little, because until I revisited the cam timing, I was beginning to think perhaps I had built an engine that no-one else has ever built successfully, and that there was some basic flaw in the design that I had missed. I still have not found a video of a running Jaguar engine. I find it very hard to believe that I am the first person to have built and ran and posted about this particular engine. Oh, I have made a LOT of changes, but the bore, stroke, and cams are the same as Malcolm Stride originally planned for. This has been a very fast build, even for me, and it has consumed a very large portion of the past six weeks. It starts very easily now, and runs until I shut off the switch. I find that this engine does not like changes in the throttle setting very much. It likes to run fast---(again, I think the cams are right on the ragged edge of what will work in a single cylinder engine.). In the videos the George Britnell carb clone has the throttle set wide open--and if I slow it down by closing the throttle it will slow down a very little bit, then stall out. Of course I will continue to tinker a bit with it and see if this can be improved any. I have taken a good look at Malcolm Stride's carburetor plan, and it is very similar to the carb which I have on it. It is a very pretty engine, and terrifically small considering the bore. I thought that I would like to have an engine with a totally enclosed crankcase, but I'm rethinking that now. There is no good, quick way to check the engine oil level, and that oil level is critical to the big end of the connecting rod, which has no bearing on it.---And the big end of the con rod is not accessible to squirt a few drops of oil on like I can with my open crankcase engines. My machining skills continue to improve, as do my trouble-shooting abilities (which are a major necessity when trying to get a new engine started and running.) It's been fun, but I'm glad its over now for a while. I will finish off the drawings and post a download link later this week. Thank you so much to all who followed the thread and those who took time to comment.---Brian Rupnow

- Joined

- May 27, 2010

- Messages

- 2,999

- Reaction score

- 1,171

Glad you got it running to your satisfaction. Now the presssure is Gus to finish up and run. I am still recovering but not much zest and kind of lethargic.

Here you are guys---I think there are about 60 drawings, all in pdf format. If you discover anything particularly horrible, please let me know.---Brian Rupnow

http://www.mediafire.com/download/7h21s9qko5mhcyk/CANADIAN_CUB_I.C._ENGINE.zip

http://www.mediafire.com/download/7h21s9qko5mhcyk/CANADIAN_CUB_I.C._ENGINE.zip

Last edited:

Wow--What great fun, to be finished the big thresh and to be able to actually spend some time tuning in the engine and adjusting things to see how much I can improve the performance. The more this engine runs, the better it runs. I am now able to get a much better variance in the RPM range. The engine does get hot very fast----of course, this is a whole different ball game than my hit and miss engines. I have no desire at the moment to build anything more, but may, in future, think of adding a small belt driven fan that cools the cylinder. I wish I had a variable ignition timing set-up for extra fine tuning, but I'm sure I can live without it.

- Joined

- May 27, 2010

- Messages

- 2,999

- Reaction score

- 1,171

Here you are guys---I think there are about 60 drawings, all in pdf format. If you discover anything particularly horrible, please let me know.---Brian Rupnow

http://www.mediafire.com/download/7h21s9qko5mhcyk/CANADIAN_CUB_I.C._ENGINE.zip

Hi Btrian,

Thanks for the drawings. Will earmark for 2015 build.

- Joined

- Aug 16, 2013

- Messages

- 1,033

- Reaction score

- 764

What a ride. That is one nice looking engine Thm:. Thank you for sharing all the highs and lows of this build. Ive downloaded the plans but it will be a while before Im up to a level where I would feel comfortable starting on it. Its builds like yours that finally inspired me to start on my Webster.

- Joined

- Mar 1, 2010

- Messages

- 865

- Reaction score

- 82

Brian

Nicely done and a neat variant of the original.

You could always make the water cool jacket. A lot quicker than pulleys and fans.

If you want to try variable advance timing you can do it for $26.

http://www.hobbyking.com/hobbyking/...or_Single_Cylinder_Gas_Engines_14mm_Plug.html

If you look through the website you may find something better suited to your plug. As you have a flywheel put the sensor on that not the camshaft otherwise you'll get the advance timing wrong with the cam going at half speed.

Pete

Nicely done and a neat variant of the original.

You could always make the water cool jacket. A lot quicker than pulleys and fans.

If you want to try variable advance timing you can do it for $26.

http://www.hobbyking.com/hobbyking/...or_Single_Cylinder_Gas_Engines_14mm_Plug.html

If you look through the website you may find something better suited to your plug. As you have a flywheel put the sensor on that not the camshaft otherwise you'll get the advance timing wrong with the cam going at half speed.

Pete

Thanks Pete--I will save that link. The water cooled cylinder is a possibility that I hadn't thought about. BMac--You are right--It is a nice engine, but you want a few simpler ones under your belt before you build this one.---Brian

This will be the last post about this engine unless I do some fairly major change to it. I will probably make a new piston with proper sized ring grooves in it for cast iron rings and give that one more try at some point. I may try the Philip Duclos method of ring heat treat, which is entirely different from Malcolm Stride's method, and if I do I will post about it. During the video I say something about the "shape of the valves". I miss-spoke there, what I meant to say was a comment about the "shape of the Cams".---Brian

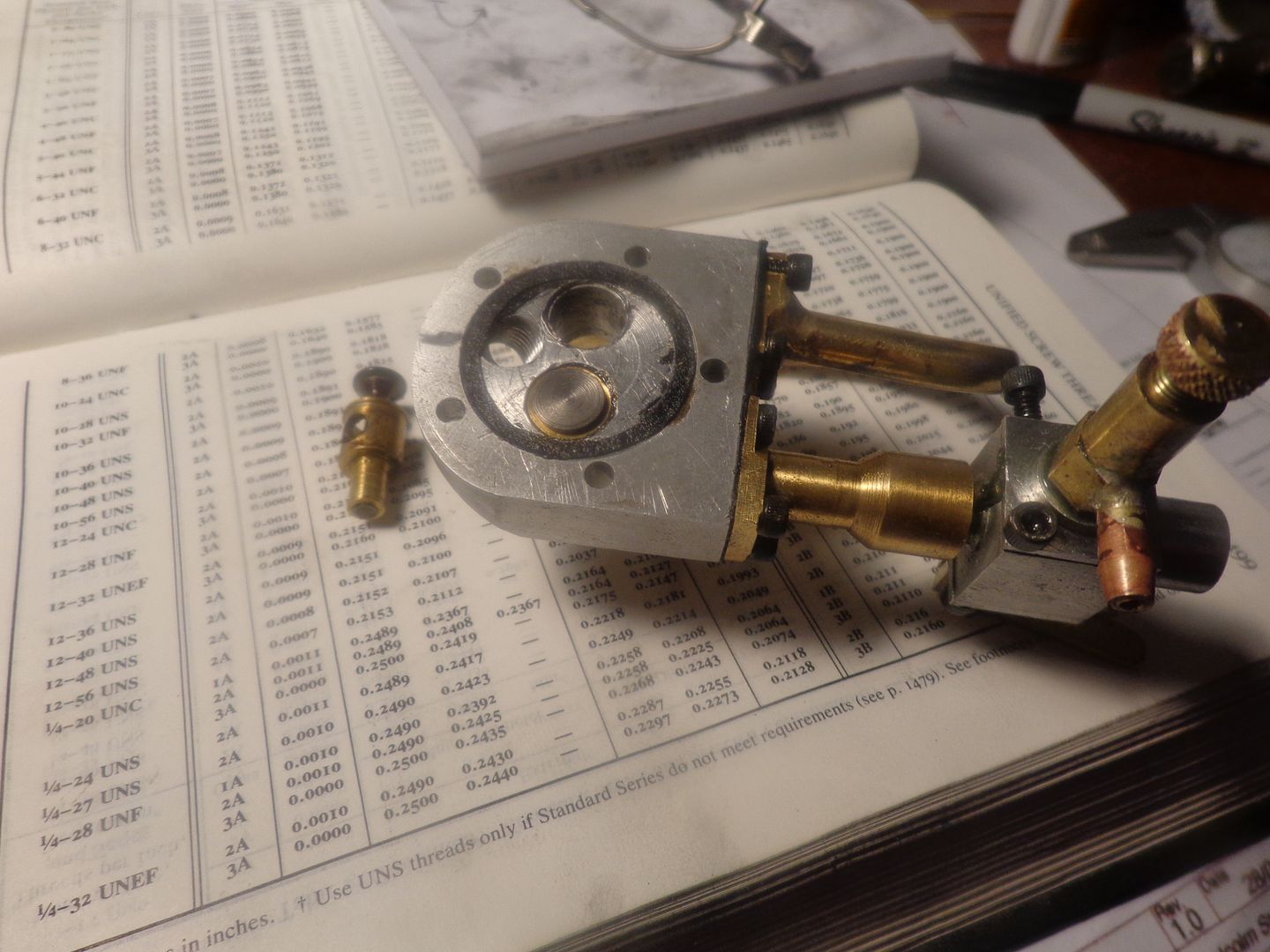

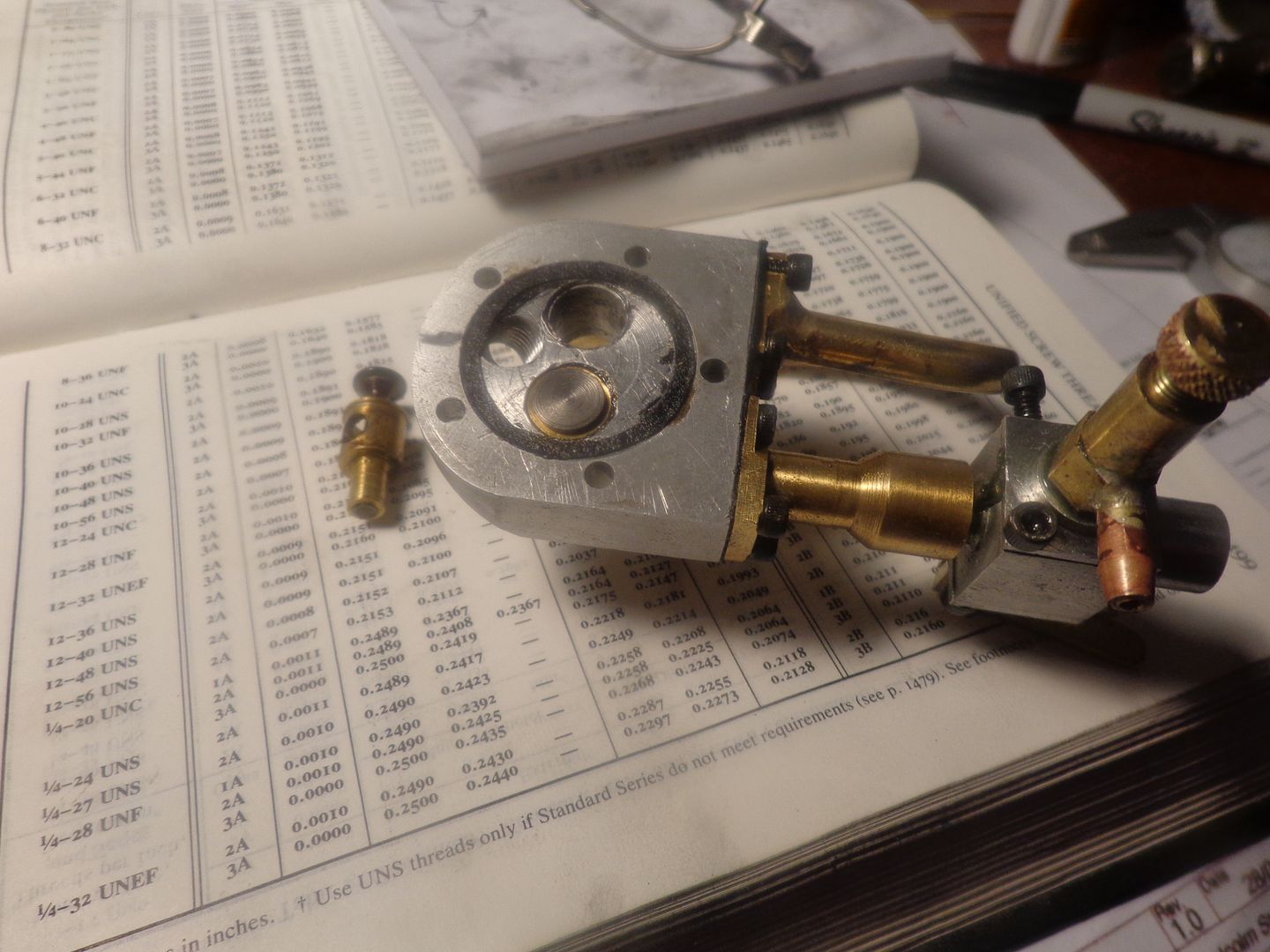

Well--I did say I wouldn't post anymore on this engine unless I made a major change----I THINK this is a major change. I needed to put my George Britnell carburetor back onto the twin opposed cylinder engine, so I took Malcolms plans, fiddled them very slightly, added imperial fasteners instead of the metric ones, and redrew them in inches. This is a $560 carburetor!!! I spent two 8 hour days building it. At my "standard rate" that I have always charged for my design work, plus the "harmonized goods and services" tax which I am bound by law to collect, it would have cost somebody $632.80 for those two days of my labour. Good Lord---If I had to pay for this kind of stuff, I would quickly find a cheaper hobby!!! The engine responds very well to this carburetor. I was fiddling with the needle valve, winding it in more and more with the throttle wide open. The rev's were starting to pick up very good, when suddenly the engine quit and again has no compression. I took out the sparkplug, and yes, there is still a piston in there going up and down when I turn the flywheel, and the camshaft is still operating. The engine was getting quite hot, so I'm not sure what happened. I have never melted a Viton o-ring, but then again all of my other engines are hit and miss except for the dual opposed cylinder engine, and they all run quite cool. I will do some more diagnostics on the engine tomorrow to see what happened. I understand that the Viton o-ring material can be extremely nasty stuff if melted, so I will exercise rubber glove caution. At any rate, the carb seems to be a success.

Big sigh of relief---No disaster!! A piece of my headgasket that intruded into the combustion chamber and was left untrimmed had burned to carbon and broke off wedging under the head of the exhaust valve. I pulled the cylinder off because I knew it would keep me awake all night wondering what was going on with the compression. Two minutes with an exacto knife and a good shot of compressed air to blow everything out and tomorrow I should be back in business. I held the exhaust valve open by pressing on the valve stem and compressing the spring, and a blast of air up the exhaust pipe blew out any remnants that I couldn't see. With this engine, it is a lot easier to pull the cylinder and head off as an assembly than it is to pull off the head by itself.

Swifty

Well-Known Member

Very nice engine Brian, I'm glad that you got that problem sorted easily, it runs great.

Paul.

Paul.

Thanks Brian, it sgood to know the Nemett carb works OK as I've already made one for my twin.

One reason teh hit and miss engines run cooler apart from the obvious slower speed is that the piston is pumping cold air in and out of the cylinder all the time the exhaust valve is held open which keeps the temp down.

Maybe a small fan belt (o ring) driven off the flywheel a bit like the air cooled Hired Man engines used. Quite simple just a hub and 4 angled blades soldered into a short piece of tube which acts as the pully surface around the outside.

J

One reason teh hit and miss engines run cooler apart from the obvious slower speed is that the piston is pumping cold air in and out of the cylinder all the time the exhaust valve is held open which keeps the temp down.

Maybe a small fan belt (o ring) driven off the flywheel a bit like the air cooled Hired Man engines used. Quite simple just a hub and 4 angled blades soldered into a short piece of tube which acts as the pully surface around the outside.

J

Jason, I agree with you, and I may go in that direction.---Brian

If it weren't for bad luck, I'd have no luck at all---Doom,Despair, and Agony on me---Wait--Oh No---This isn't Hee Haw is it!!! I reassembled everything this morning, had a couple of good runs, and then the engine quit. A visual examination showed one valve wasn't setting up as high as the other. Hmmmm---That's strange!!! Turning engine over by hand showed exhaust valve, spring and all moving up and down with compression/suction of the piston. Very strange indeed!!! I pulled off the head, and see that my exhaust valve, valve cage and all has come loose from the head and is moving freely up and down in the head. Obviously my guardian angel has an interest in small engines as well and didn't let the whole thing get sucked down onto the top of the piston at speed. This would have been exciting indeed!!! Ever since destroying a valve cage while trying to press it into a cylinder head on one of my earliest engine builds (Kerzel, I think) I have made them a "slip fit" and coated them with Loctite to keep them in place. The flange keeps them from flying out of the cylinder head under pressure. I NEVER imagined one of them being sucked INTO the cylinder. I don't think its a really big deal. I will take my "automatic punch" and put a number of punch pricks around the inside of the hole in the cylinder head to upset the metal a bit, then clean everything with laquer thinners, re-Loctite things, and press the cage and valve back into place.

Similar threads

- Replies

- 0

- Views

- 2K