- Joined

- Jun 4, 2008

- Messages

- 3,285

- Reaction score

- 630

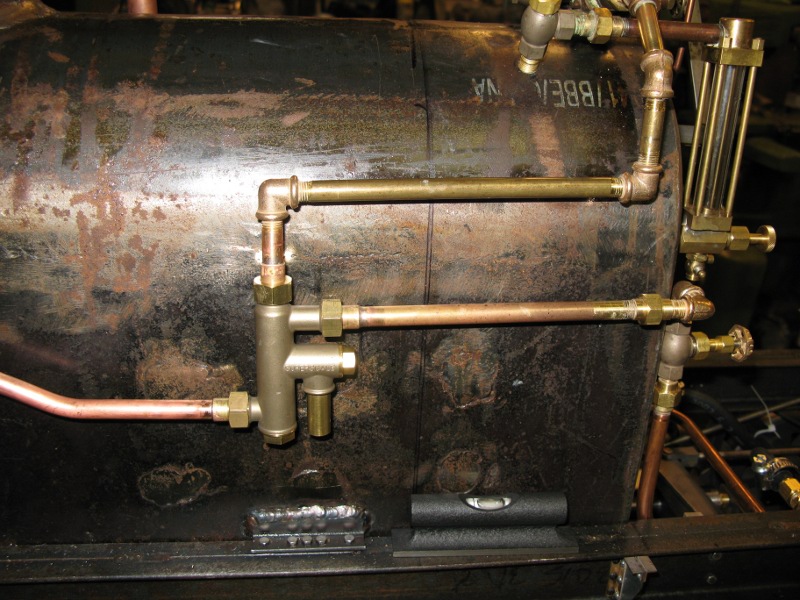

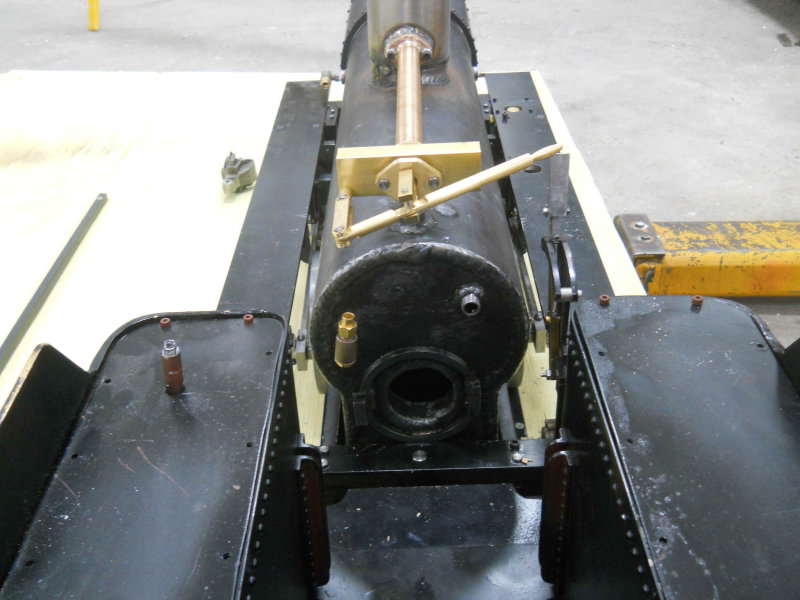

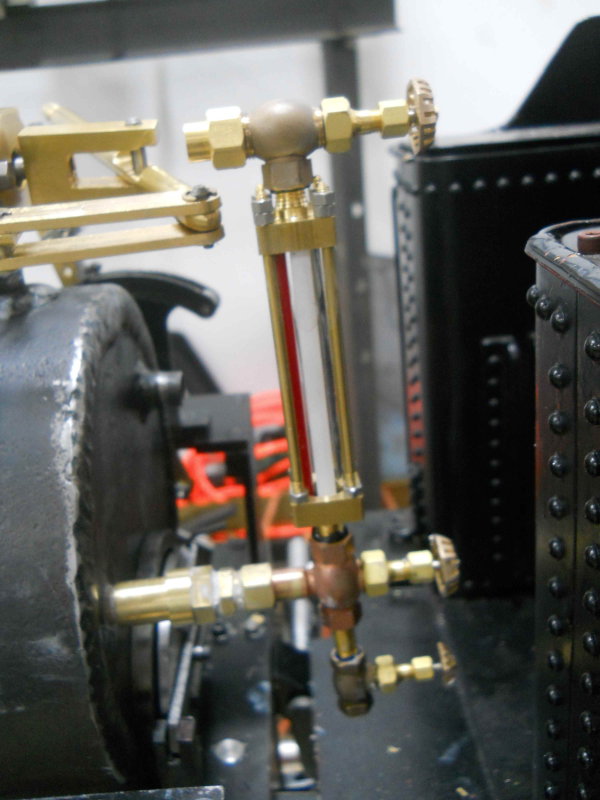

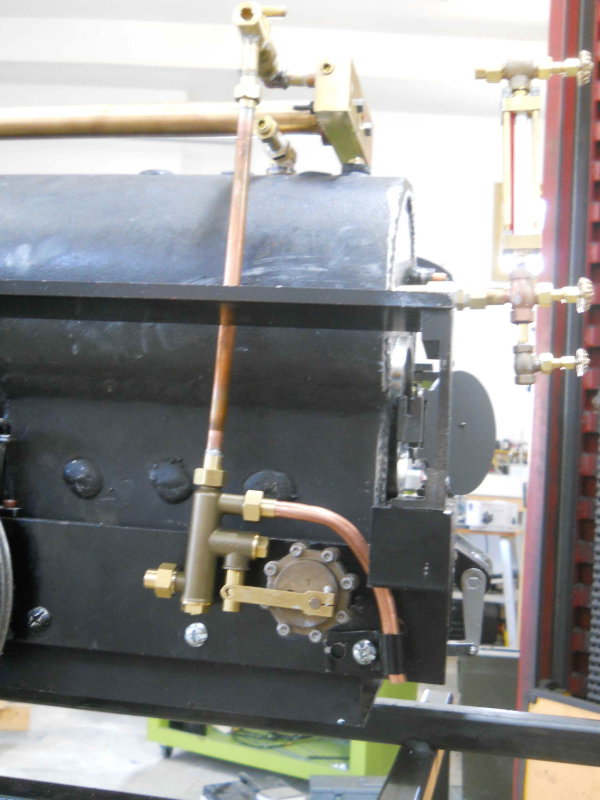

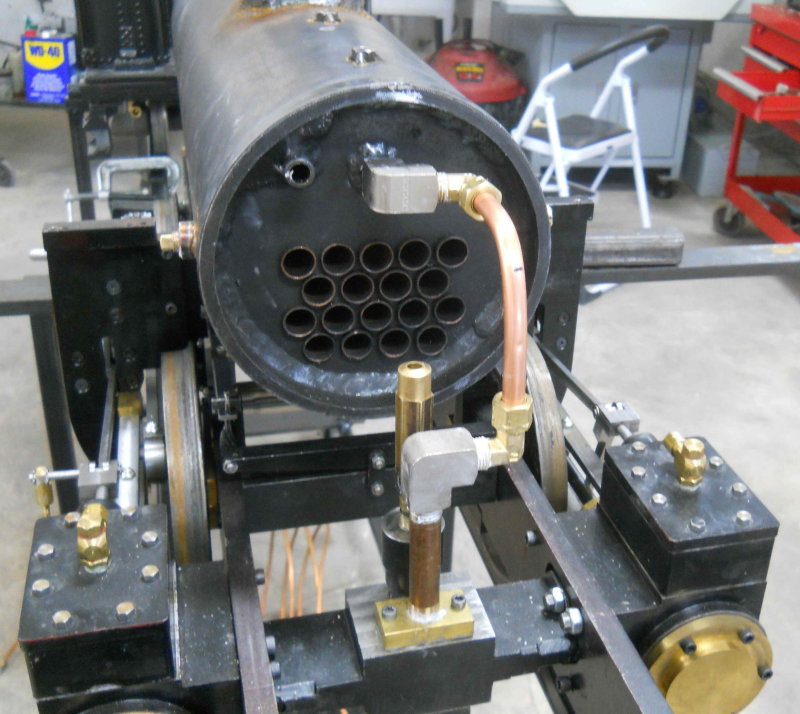

After some advice from a number of other builders, I believe I have located the "best" spot for the injectors; the water inlet will be about level with the top of the frame, and as far back as I can get it. I have some ideas about routing the water input but will have to experiment a bit before finalizing the plan.

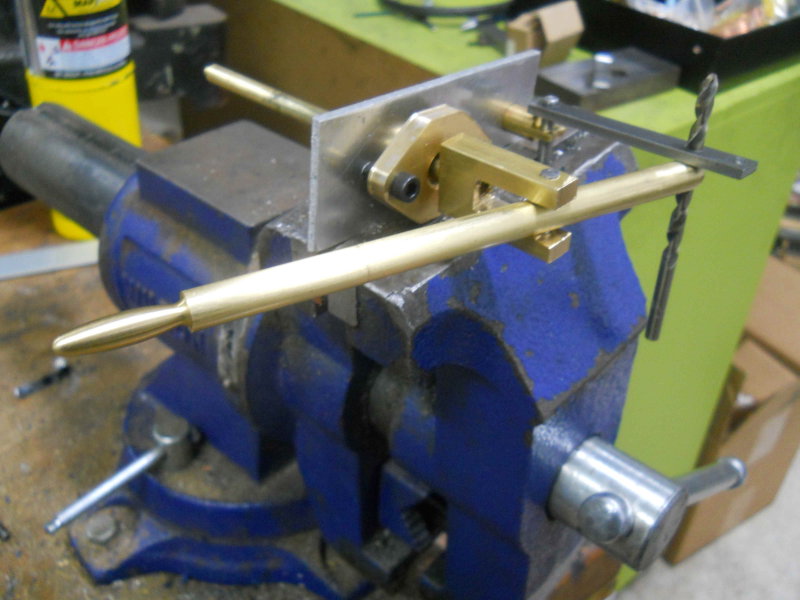

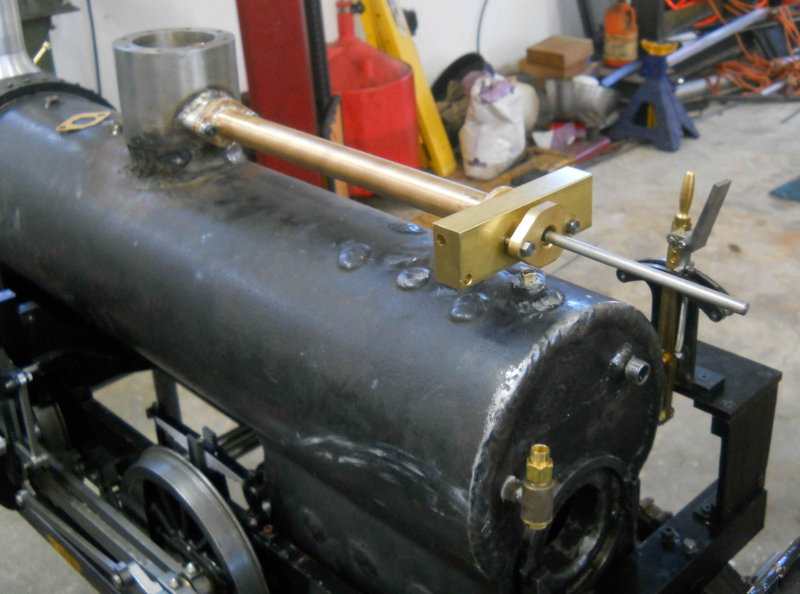

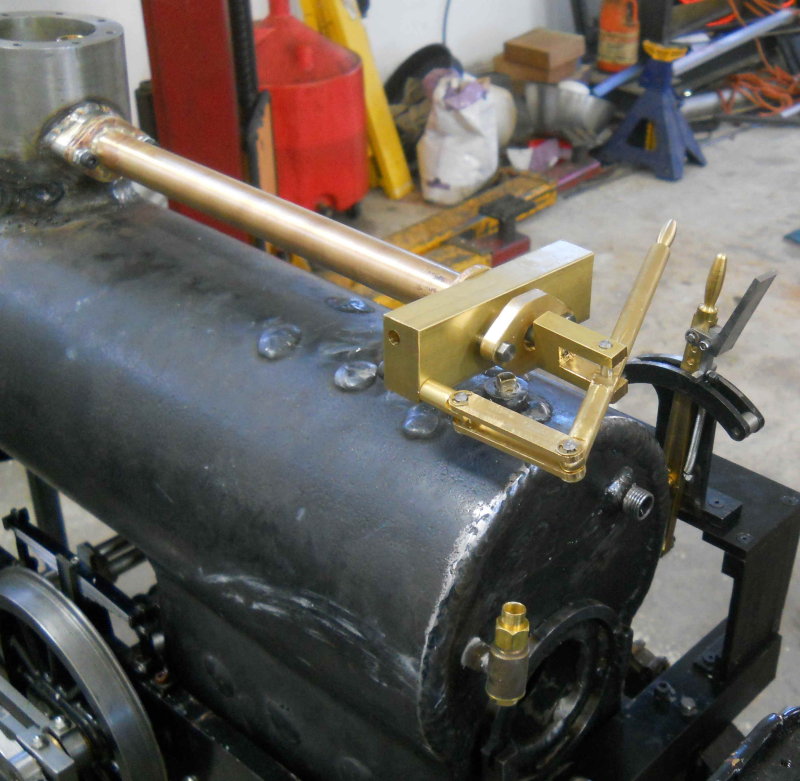

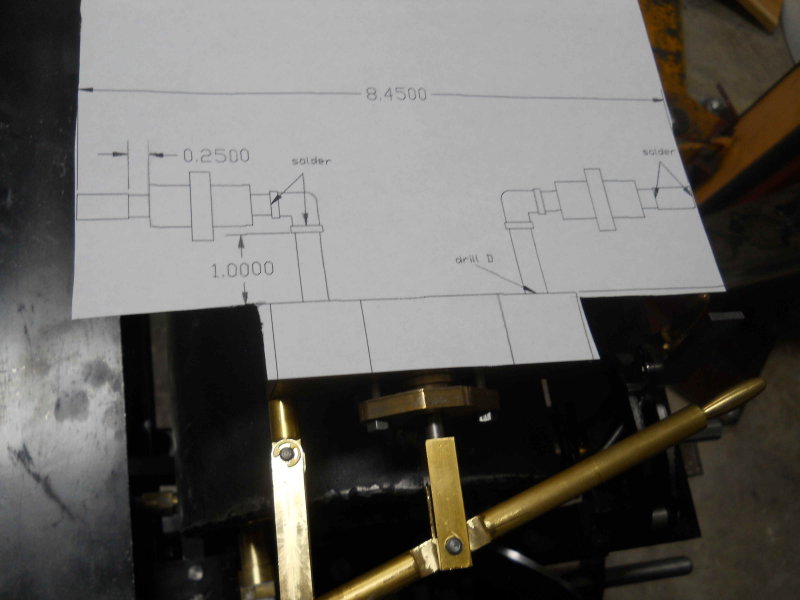

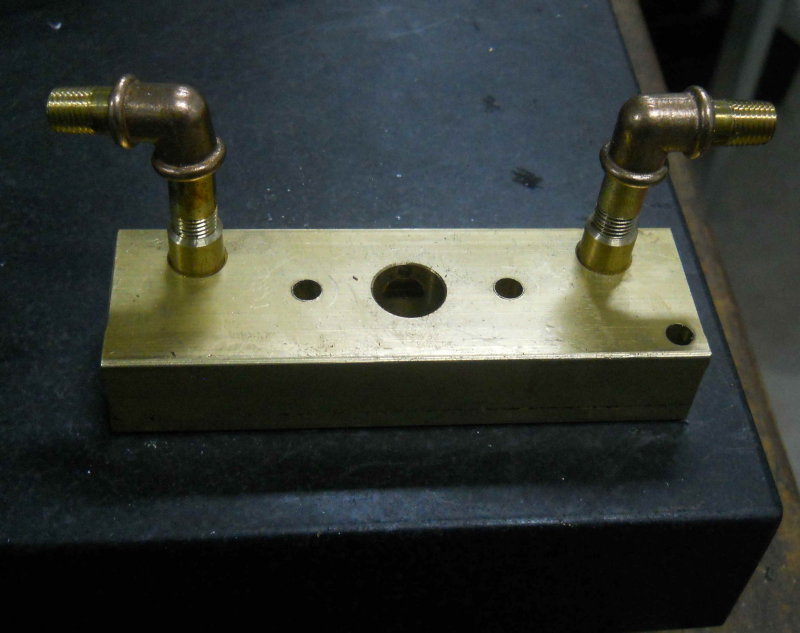

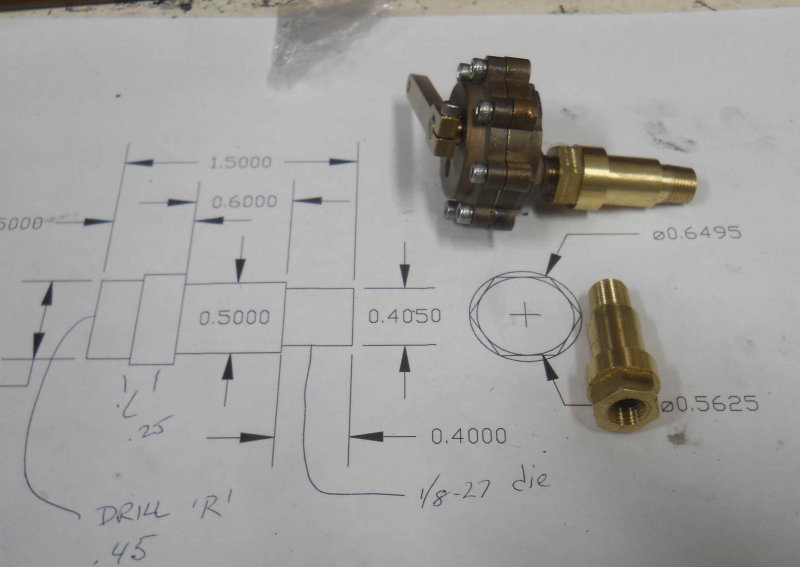

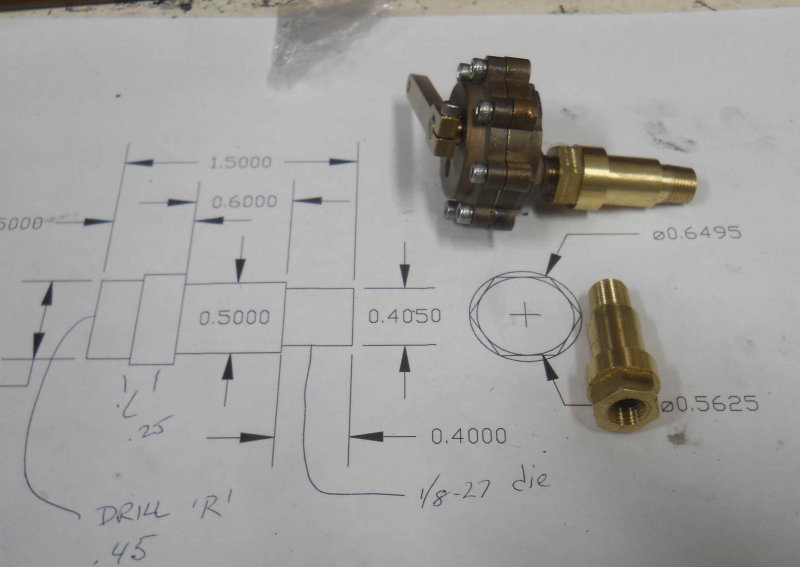

In the meantime I built a pair of parts that will connect the Locoparts blowdown valves to the boiler. On the .75" scale model, the single valve is screwed into the boiler directly with no frame in the way. On the 1.5 scale version, he specifies a single valve going through the left frame only. I will have a blowdown on both sides, and rather than build them I purchased a pair from Locoparts. The male pipe thread on these is too short to pass through the frame and screw into the boiler, so an extension is needed. Originally I was thinking that a short nipple and a bushing would be the easy way to go, but today I decided to just make each as a single brass part. Here's the result:

These will position the valve outboard of the frame about 3/4 of an inch so that the lever will now be under the walk board. This will allow me to attach a lifter that passes through the board and that can be activated when the locomotive is moving. It should also be possible to route the water feed line to the injectors behind the valve rather than in front.

I also countersunk the hole in the rear footboard so that the draw bar pin is recessed and no longer interferes with the fire door.

In the meantime I built a pair of parts that will connect the Locoparts blowdown valves to the boiler. On the .75" scale model, the single valve is screwed into the boiler directly with no frame in the way. On the 1.5 scale version, he specifies a single valve going through the left frame only. I will have a blowdown on both sides, and rather than build them I purchased a pair from Locoparts. The male pipe thread on these is too short to pass through the frame and screw into the boiler, so an extension is needed. Originally I was thinking that a short nipple and a bushing would be the easy way to go, but today I decided to just make each as a single brass part. Here's the result:

These will position the valve outboard of the frame about 3/4 of an inch so that the lever will now be under the walk board. This will allow me to attach a lifter that passes through the board and that can be activated when the locomotive is moving. It should also be possible to route the water feed line to the injectors behind the valve rather than in front.

I also countersunk the hole in the rear footboard so that the draw bar pin is recessed and no longer interferes with the fire door.