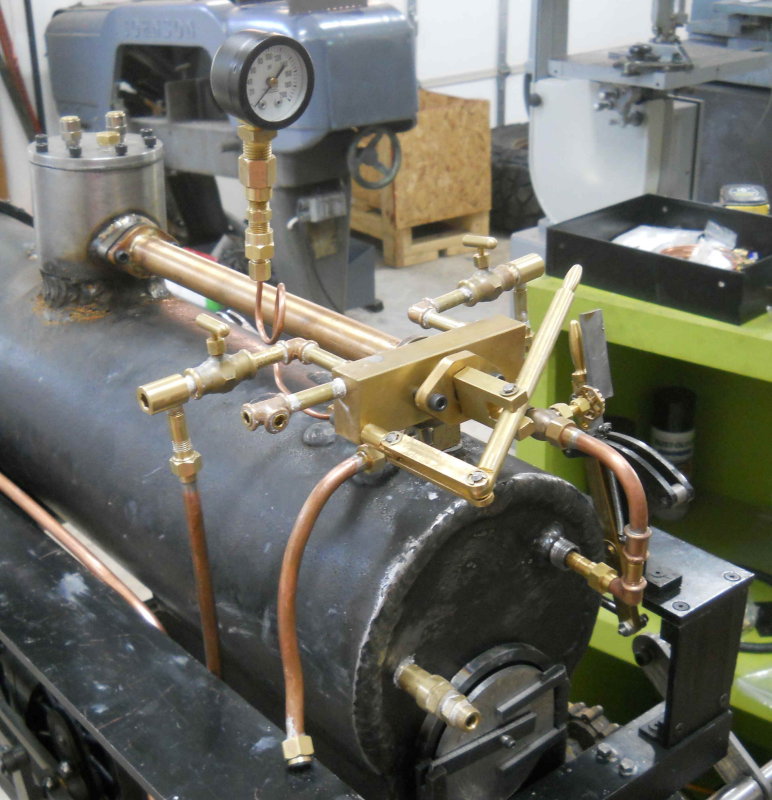

Fired the boiler for the first time at the CSP&P track roundhouse. Thanks to several fellow club members who provided, in addition to advice, kindling, coal, a coal scoop and poker, and load of a stack blower. It took a while to get pressure up, but eventually the needle came off the bottom.

Things that worked well:

1) The 100 psi safety let loose with the pressure gauge reading 100.

2) Superscale economy injector fed water into the boiler from the tender

3) Steam blower worked very well

I wanted to move the engine under steam to the turntable and back. But when the engine had moved about 3 feet the gasket between the throttle tube and the turret let loose and I lost all the steam pressure. We quickly dumped the fire and called it a day, time for lunch. I didn't take any pics myself, but some fellow members and friends got a few. I'll post some when they mail them to me.

Things that need fixing:

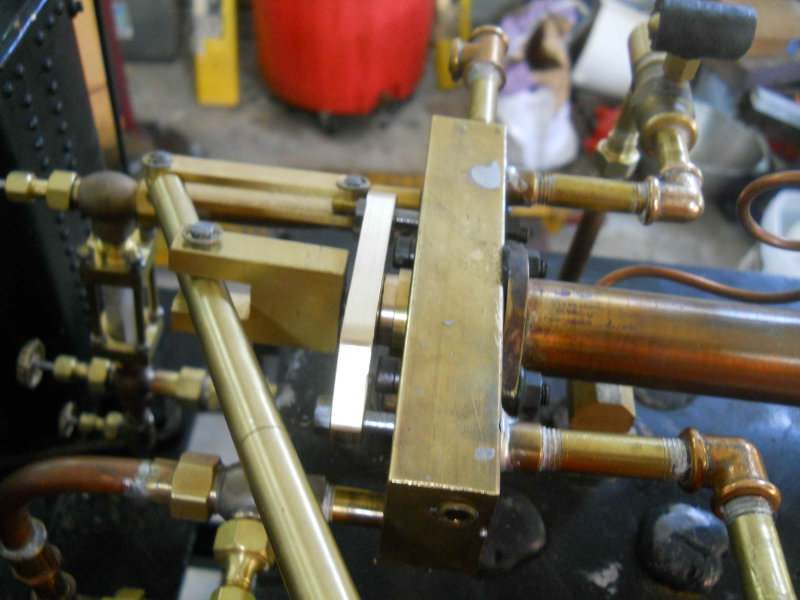

1) The throttle-tube.turret junction. I was actually most worried up front on this since if the connecting bolts are really torqued down they squeeze the gland (o-ring) around the throttle rod too tight.

2) The SS grate is a tad too long and expanded so that the grate was tight in the firebox. This made raking out the fire awkward. I'll take a bit off each grate bar for the next time out.

3) One of the Locoparts blowdown valve leaks a bit