vascon2196

Well-Known Member

- Joined

- Oct 2, 2009

- Messages

- 1,026

- Reaction score

- 312

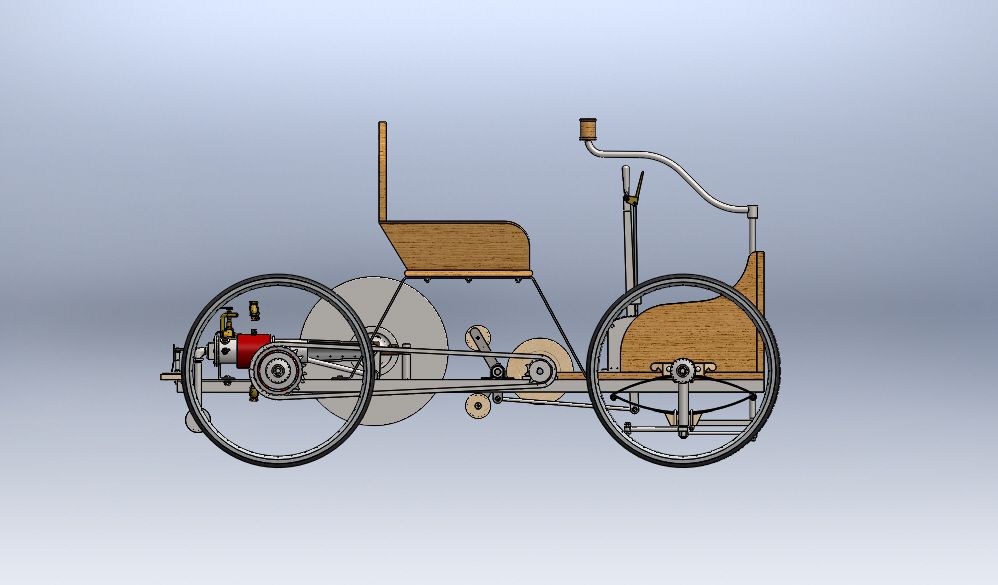

Thanks again! The frustrating part for me is that only 1 or 2 students show up to participate and we only have 3 meetings per semester. I moved the meetings to Saturday's so more students could attend.

The students that do show up have been a huge help and yes....have done a great job!

The students that do show up have been a huge help and yes....have done a great job!