vascon2196

Well-Known Member

- Joined

- Oct 2, 2009

- Messages

- 1,026

- Reaction score

- 312

Hi Ross,

Thanks for the input. Yes, this half-scale will open up all kinds of possibilities...I'm looking forward to starting it.

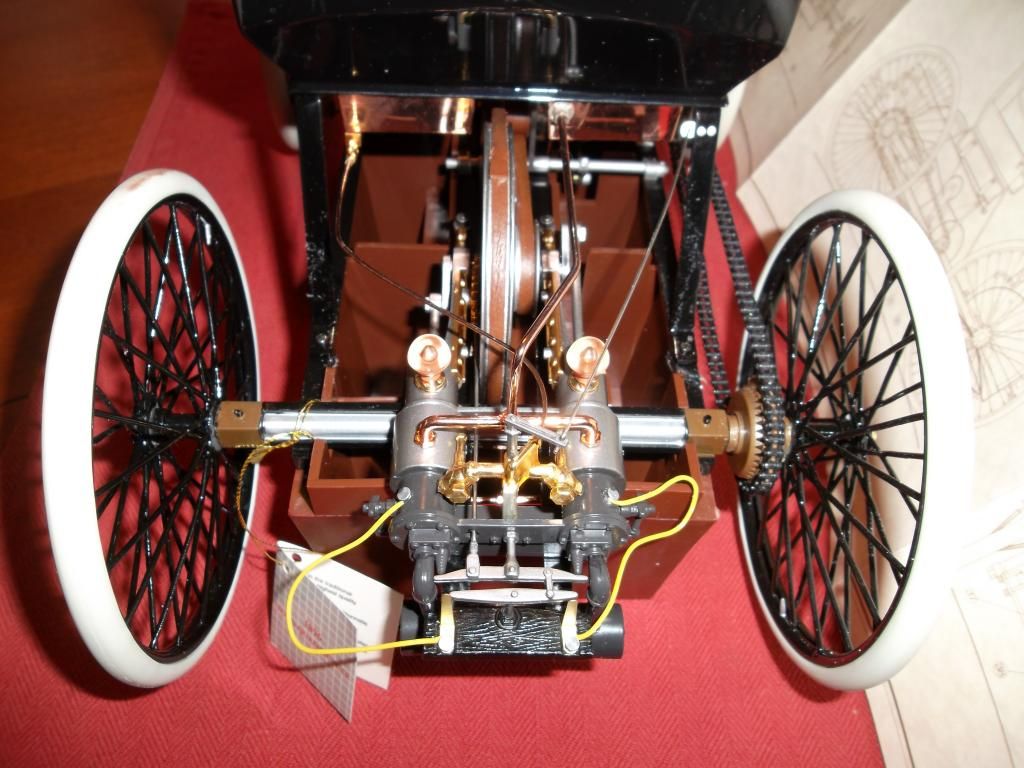

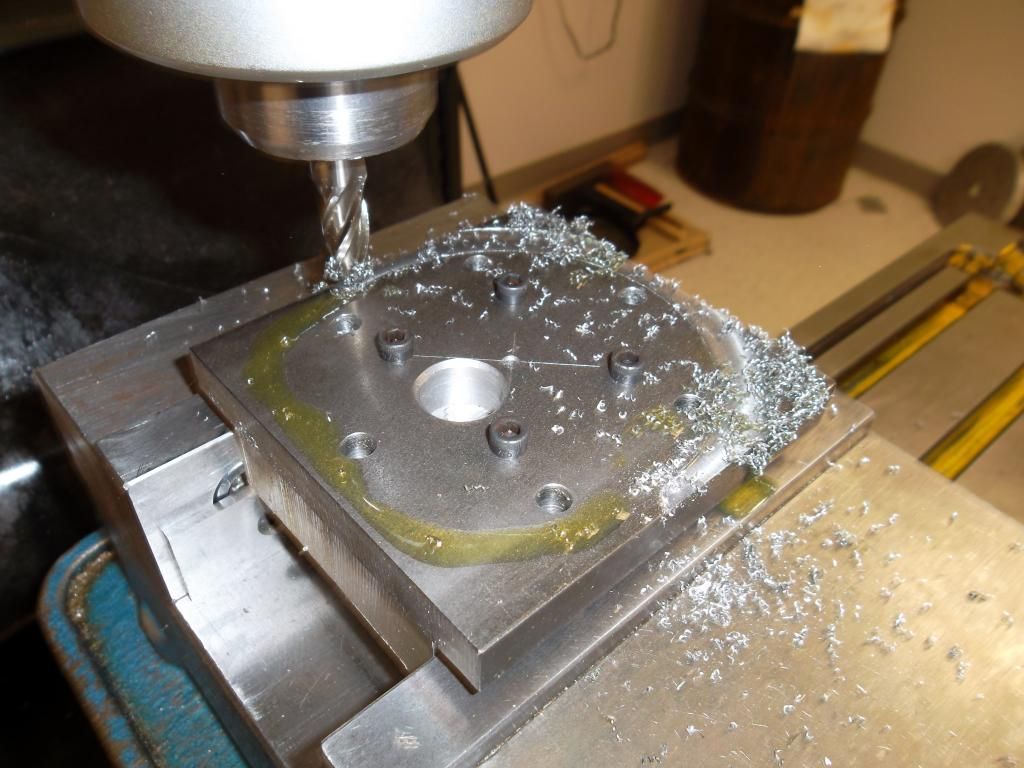

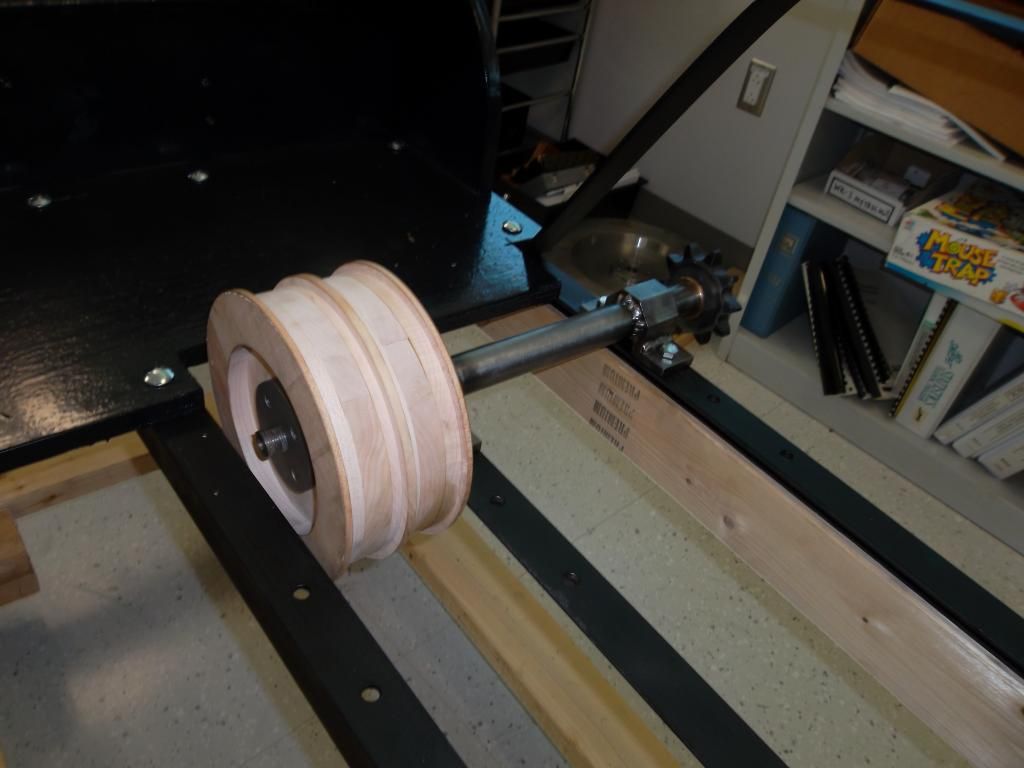

I attached a picture of the half-scale Quadricycle engine so far. I'm going to make the main bearings out of Aluminum instead of cast bronze like the original. I plan on chucking a piece of aluminum stock in a 4-jaw, drilling & boring to suit the cylinder, and then saw cut in half resulting in (2) bearings. (I hope)

The flywheel will now be around 9" in diameter, main bearings about 4" long, intake and exhaust ports now 1/8" NPT, Cylinder diameter 1.25". I did see the "small" version of the engine the guys in Spain build...very cool.

Thanks for the input. Yes, this half-scale will open up all kinds of possibilities...I'm looking forward to starting it.

I attached a picture of the half-scale Quadricycle engine so far. I'm going to make the main bearings out of Aluminum instead of cast bronze like the original. I plan on chucking a piece of aluminum stock in a 4-jaw, drilling & boring to suit the cylinder, and then saw cut in half resulting in (2) bearings. (I hope)

The flywheel will now be around 9" in diameter, main bearings about 4" long, intake and exhaust ports now 1/8" NPT, Cylinder diameter 1.25". I did see the "small" version of the engine the guys in Spain build...very cool.