vascon2196

Well-Known Member

- Joined

- Oct 2, 2009

- Messages

- 1,026

- Reaction score

- 312

The Quadricycle had an internal combustion engine.

I think this is a great and noble cause, I will be following with much curiosity.

Having said that, I am wondering what are the benefits this provides to the students. Is this in conjunction with a CNC machinist program or the like? What good will this do the student when he/she graduates? I enjoy working with manual machines, but more and more it seems like CNC knowledge and training seems to be the only jobs out there.

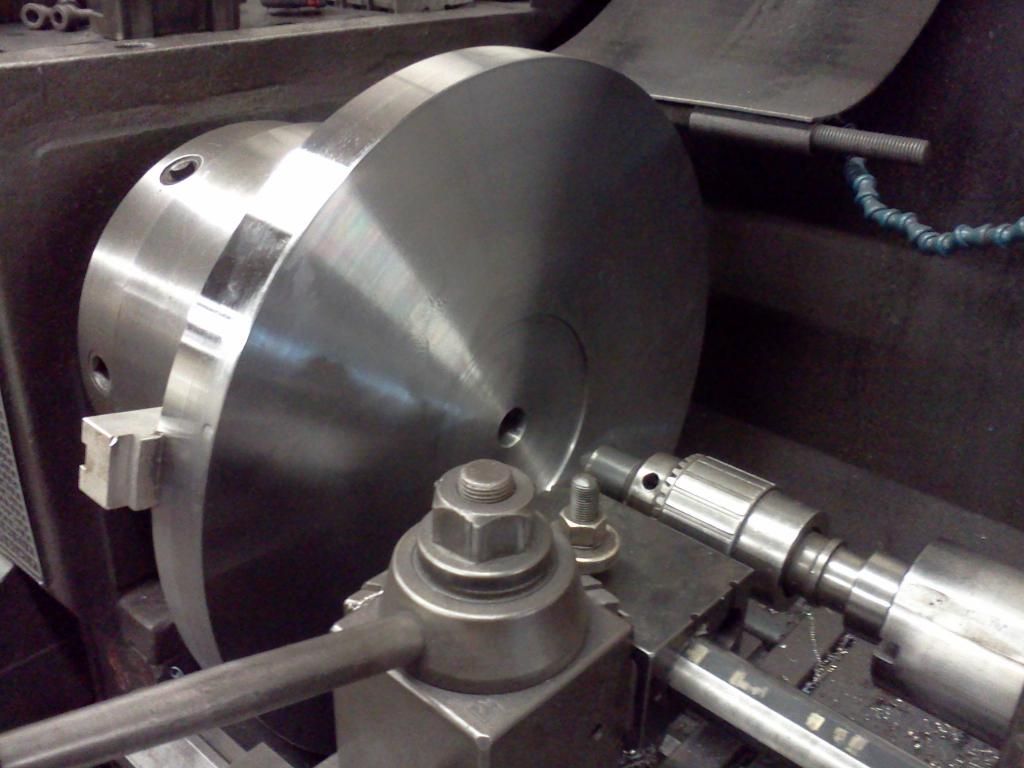

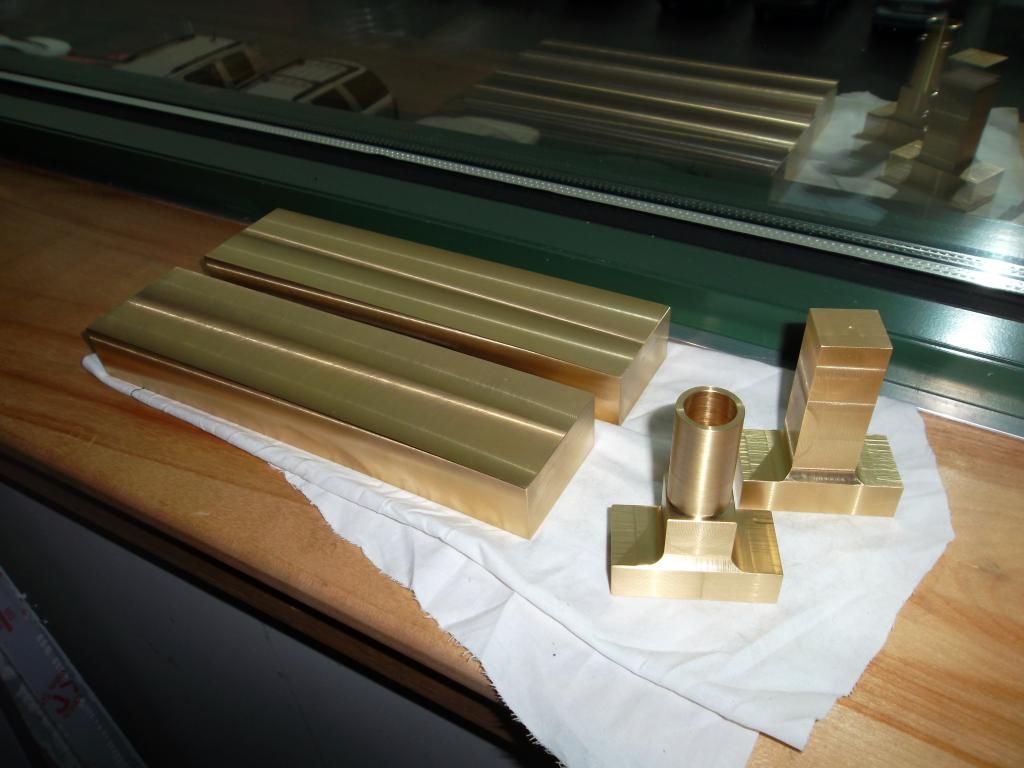

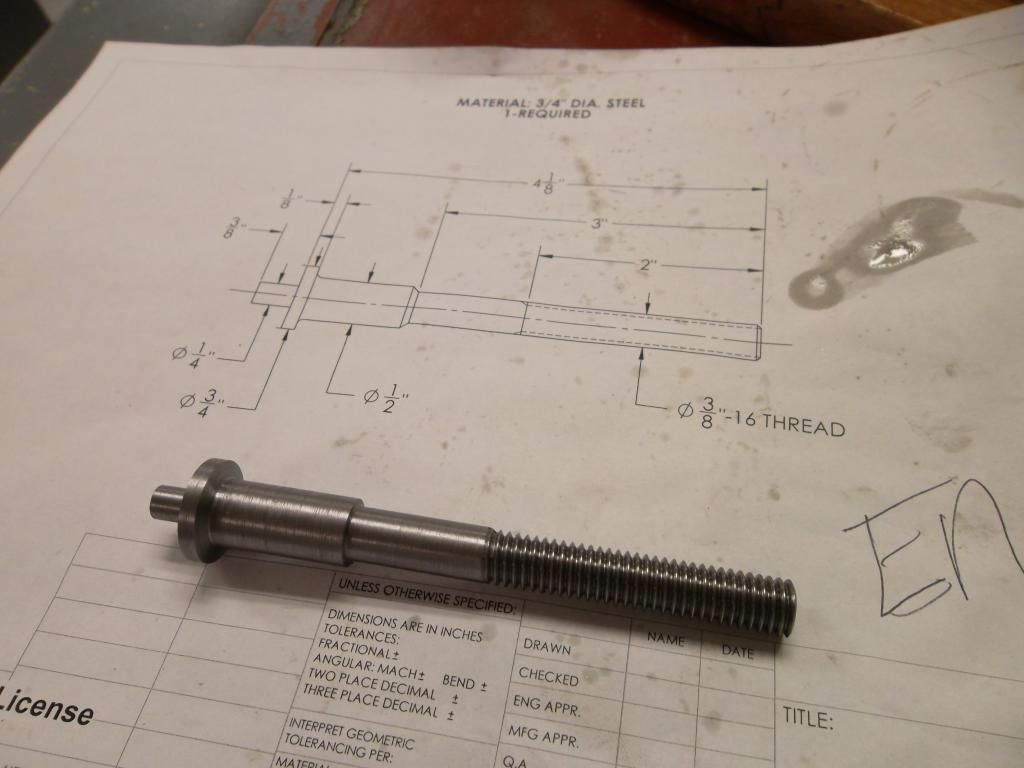

I hope the students walk away with a better understanding of how parts are manufactured. I truly believe that a good mechanical design engineer should know how a part is to be made and on what machine(s) to make it on before they run off and start designing. In my opinion, a good machining background will help them become better more effecient engineers. At least then, they will be designing with a purpose...designing with the intent to manufacture.

So far it is working out quite well.

Enter your email address to join: