vascon2196

Well-Known Member

- Joined

- Oct 2, 2009

- Messages

- 1,026

- Reaction score

- 312

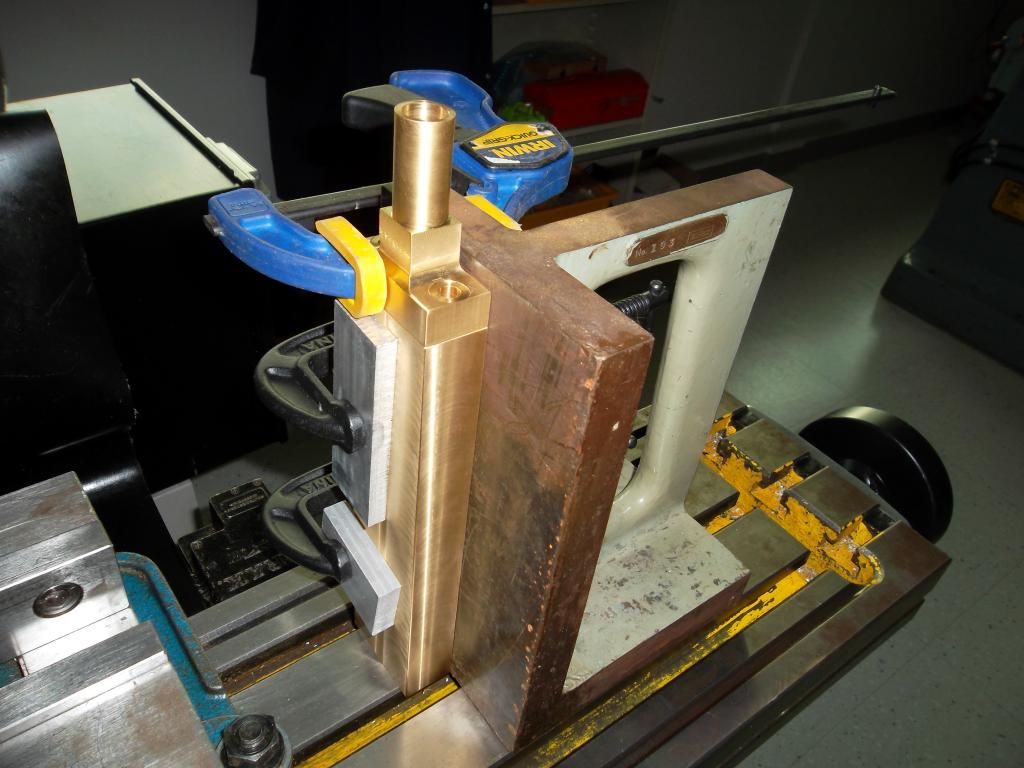

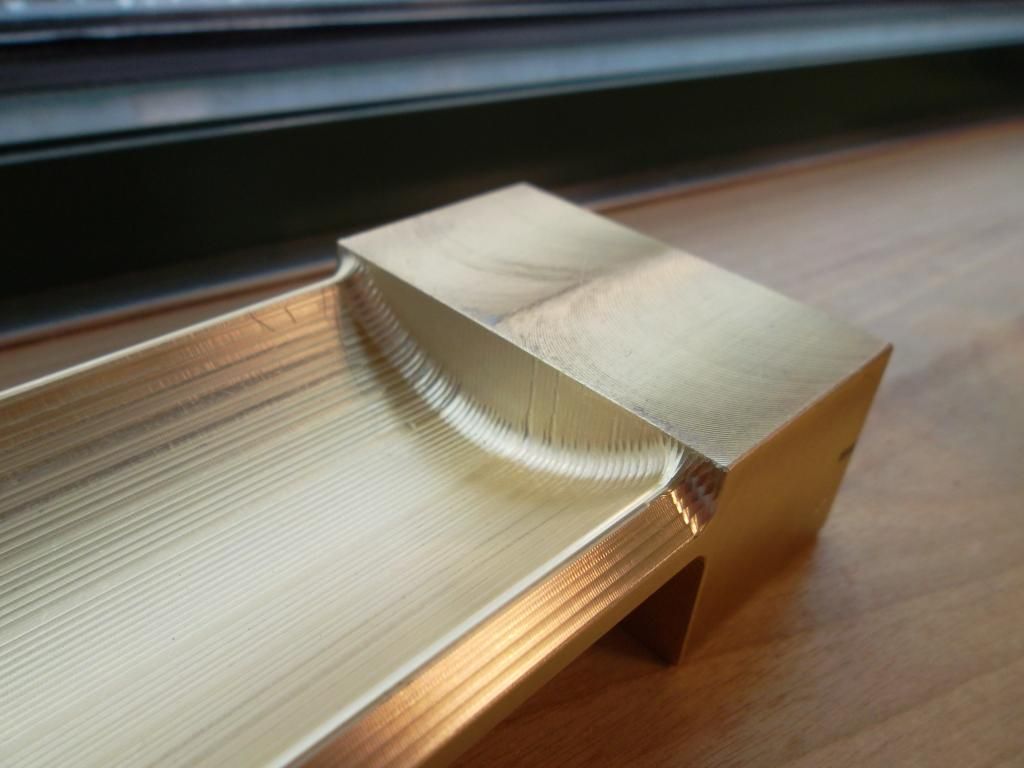

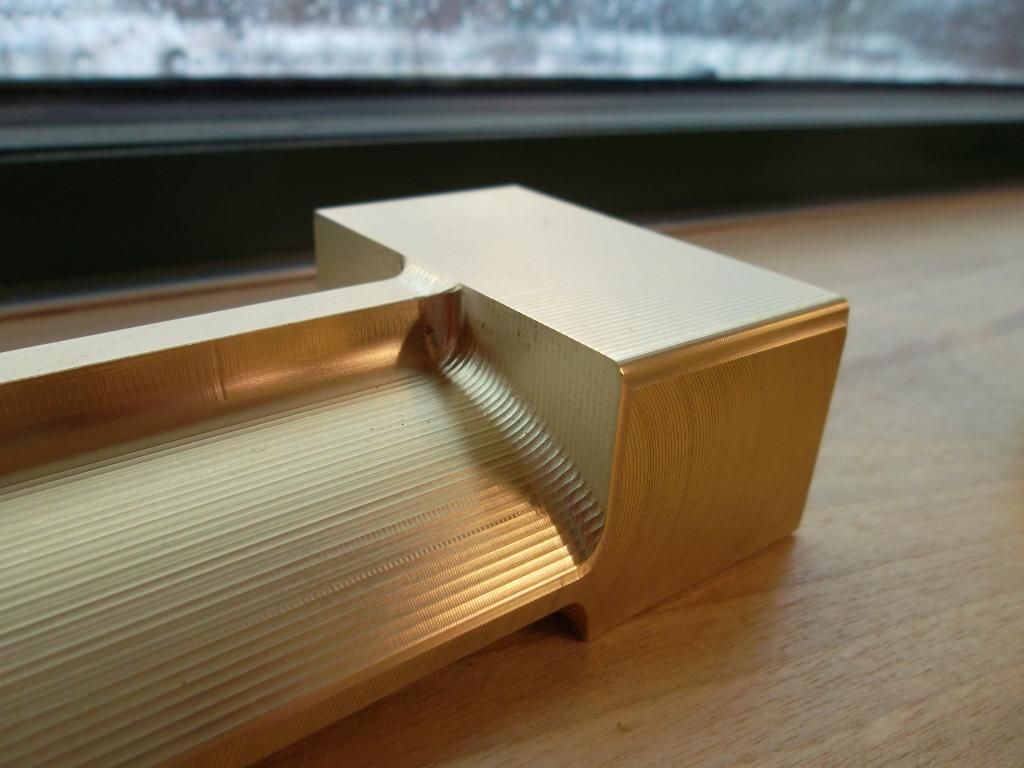

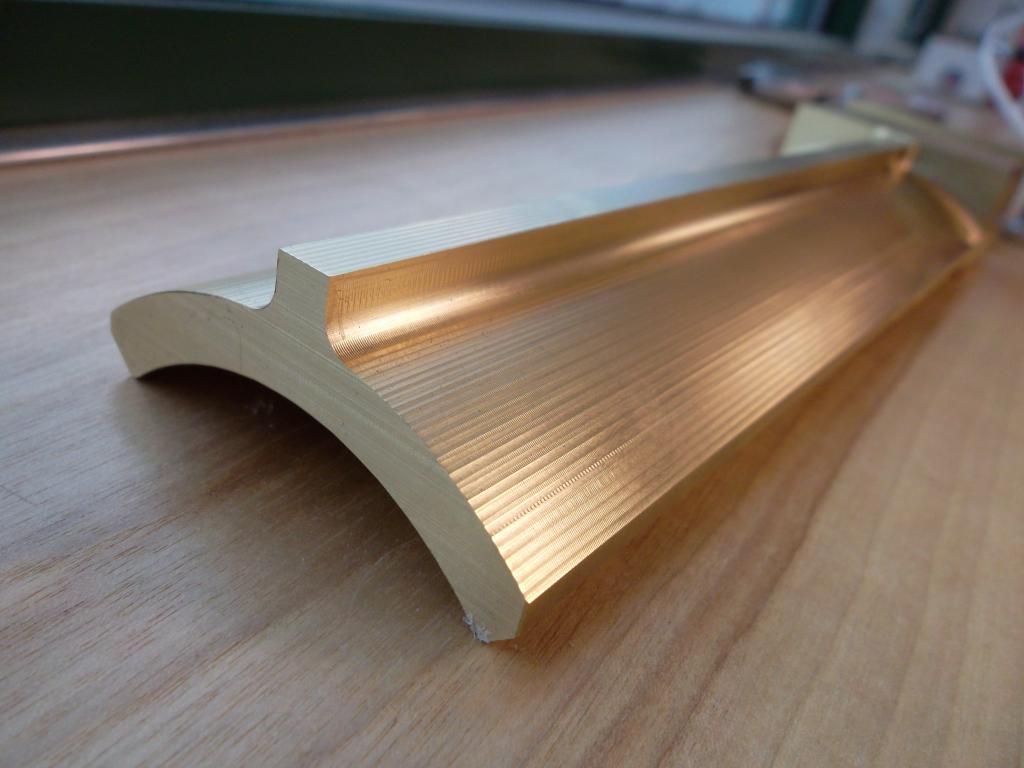

Roughing the main bearing using our Haas CNC Mill. An evening student is doing this...I don't know how to turn the machine on!

I can only imagine what he would have done with CNC!

And thank you for your comments...I will pass them along to my students!

Enter your email address to join: