Had one of those days in the shop where I learned something but didn't make anything.

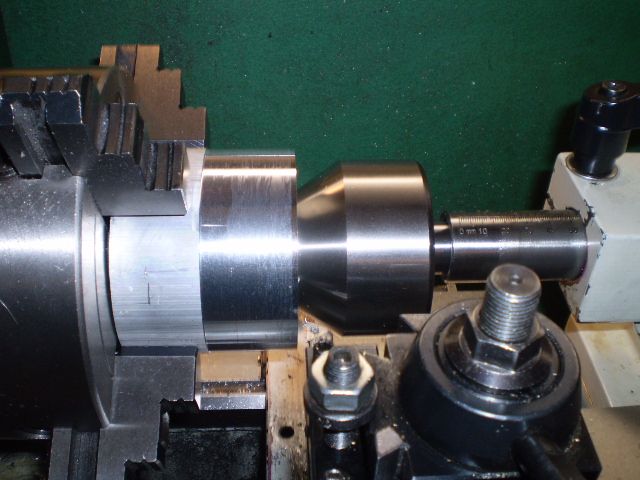

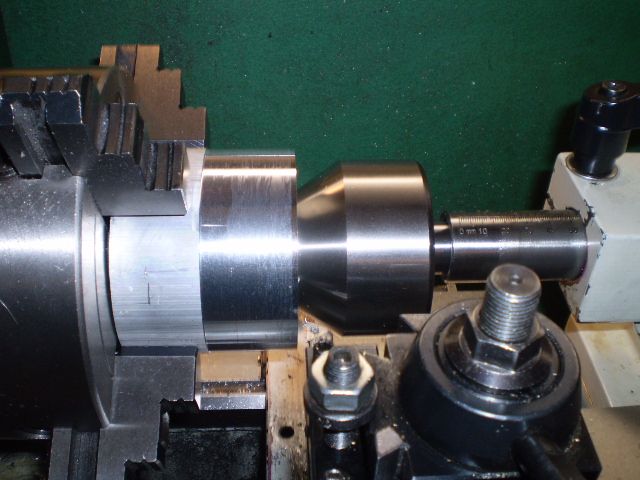

I'm making the water tank which is a bit over 3" diameter (80 mm). I found some 3" (nominal OD, actual is 3.5") aluminum pipe. At first I gripped the workpiece on the inside jaws of a 6" four jaw chuck. Turned the OD using a bullnose center

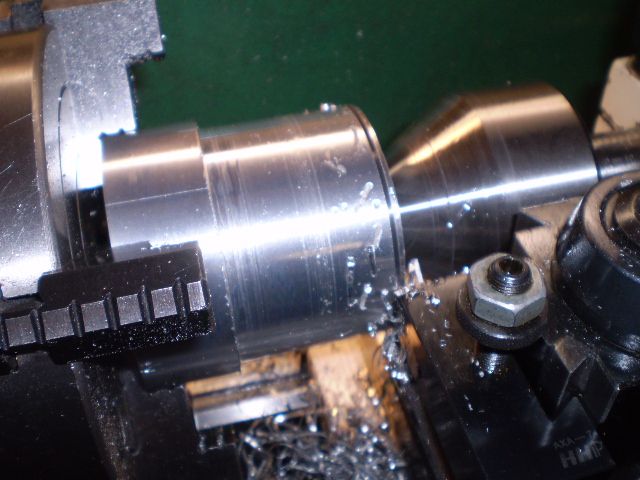

When I flipped the work around I ended up with a very bad junction on the OD. I do not expect this using a 4 jaw independent chuck.

I found that the inside jaw capacity of this chuck is just over 3". So I thought maybe I wasn't getting a good grip on the work, so I switched to the outside jaws. A bit better result but still an unacceptable junction. At one point I noticed when facing the work, the inside bore was not concentric to the OD.

When I put the bullnose center back in the bore and tuned the lathe on I could see the very slightest wobble of the center. So the bullnose was part of the problem causing the work to wobble while turning the OD.

I bored the center about 0.030" out on one end since I need to eventually expand the bore anyway. Put the bullnose in place, turned the OD as far to the chuck as I could. Switched the work around, bored out the end true, put the bullnose in place, set the handwheel for the OD and the junction is almost invisible.

I'm sure I could have made an OK water tank with end plates. But I really didn't want to move on until I understood what was going on.

Sometimes what seems like a simple straightforward machining operation throws you a few curve balls.

Cheers,

Phil