Phil--Just so you know---The cam doesn't always have to be in contact with the points. It can just "bump" them open with the high point on the cam. The points only need about .030" of air gap between them when they are fully open to work satisfactorily. ---Brian

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building a Bonzer Bonzer

- Thread starter Philjoe5

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

robcas631

Well-Known Member

I like the name Bonza. Outstanding work!

robcas631

Well-Known Member

That is a amazing Dingy! You are a man of many talents. I built one back in 2001.

robcas631

Well-Known Member

Phil,

You are very talented! I enjoyed reading this post and took notes. I learned a lot! Keep up the outstanding work!

You are very talented! I enjoyed reading this post and took notes. I learned a lot! Keep up the outstanding work!

Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

I'm placing the engine and carby on some 3/8" ally and trying to decide on a convenient layout. Still playing with the electrics and will have that sorted out soon enough.

This is the last photo of the pile of parts that resembles an engine.

Now I've got to disassemble it and take care of a passel of details that I left for last. Oil holes, loctite some bushings, add threaded holes to the engine frame for mounting to the base + stuff I'll think of (hopefully) before a final assembly and a test run.

I could use some advice on the spark timing. Should it be just before, just after or at TDC?

Thanks for looking

Cheers,

Phil

This is the last photo of the pile of parts that resembles an engine.

Now I've got to disassemble it and take care of a passel of details that I left for last. Oil holes, loctite some bushings, add threaded holes to the engine frame for mounting to the base + stuff I'll think of (hopefully) before a final assembly and a test run.

I could use some advice on the spark timing. Should it be just before, just after or at TDC?

Thanks for looking

Cheers,

Phil

These engines like a lot of advance. Try it at about 20 degrees before top dead center.

AussieJimG

Well-Known Member

- Joined

- Oct 17, 2010

- Messages

- 890

- Reaction score

- 118

Oh boy! That's one good looking engine.

Jim

Jim

Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

Thanks Jim, I'm hopeful it IS an engine and not just a collection of engine parts.

From Webster:

en·gine

[en-juh

n]

n]

noun 1. a machine for converting thermal energy into mechanical energy or power to produce force and motion.

Cheers,

Phil

From Webster:

en·gine

[en-juh

noun 1. a machine for converting thermal energy into mechanical energy or power to produce force and motion.

Cheers,

Phil

Last edited:

Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

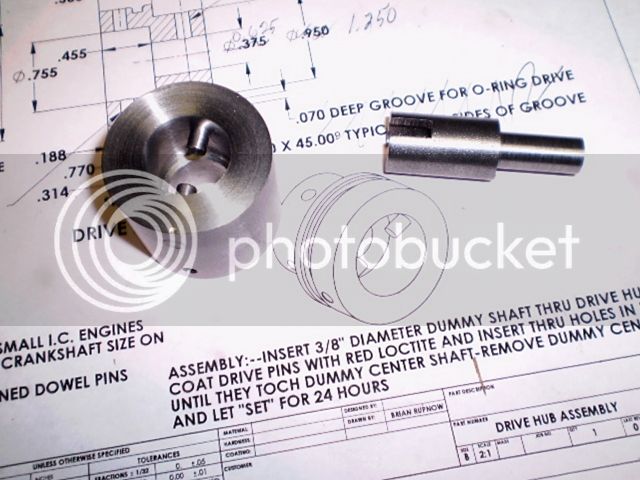

I've got the ignition wired up and timed. I've got the exhaust valve opening just before BDC. I have a driver attached to the crankshaft. Not yours Brian, I was too anxious to try a test run. But I'm definitely in need of yours soon and that's going to get done during tomorrow's snowstorm.

When I squirt a little fuel (a milliliter) into the tube on the intake manifold and spin the engine, it runs off the drill for maybe 10 seconds, then it starts to fire and may pop as many as 10 times, then stops firing.

I need a reality check here. I think what's happening is that initially the mixture is too rich to fire, leans out and fires, then becomes too lean. Is that reasonable or am I dreaming?

Once I make Brian's driver I'll hook up the vapor carby and go from there.

Advice appreciated

Cheers,

Phil

When I squirt a little fuel (a milliliter) into the tube on the intake manifold and spin the engine, it runs off the drill for maybe 10 seconds, then it starts to fire and may pop as many as 10 times, then stops firing.

I need a reality check here. I think what's happening is that initially the mixture is too rich to fire, leans out and fires, then becomes too lean. Is that reasonable or am I dreaming?

Once I make Brian's driver I'll hook up the vapor carby and go from there.

Advice appreciated

Cheers,

Phil

Philjoe--You really can't tell anything until you get some form of carb on there. The fact that its firing at all is a very good sign. What is your plan for a carb? ---Brian

I have my fingers crossed for you!!---Brian

Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

Nice job, Phil--Let me know how that works for you.--Brian

AussieJimG

Well-Known Member

- Joined

- Oct 17, 2010

- Messages

- 890

- Reaction score

- 118

When I squirt a little fuel (a milliliter) into the tube on the intake manifold and spin the engine, it runs off the drill for maybe 10 seconds, then it starts to fire and may pop as many as 10 times, then stops firing.

Cheers,

Phil

This engine is so willing to run that if you don't let it, it will start of its own accord.

Happy dance any time now.

Jim

Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

Last night I had a dream that I got the engine running. Then I heard a noise coming from the basement, like an engine running. That WAS part of the dream right?:hDe:This engine is so willing to run that if you don't let it, it will start of its own accord.

Cheers.

Phil

Last edited:

Similar threads

- Replies

- 61

- Views

- 8K

- Replies

- 148

- Views

- 20K