Hi Jason

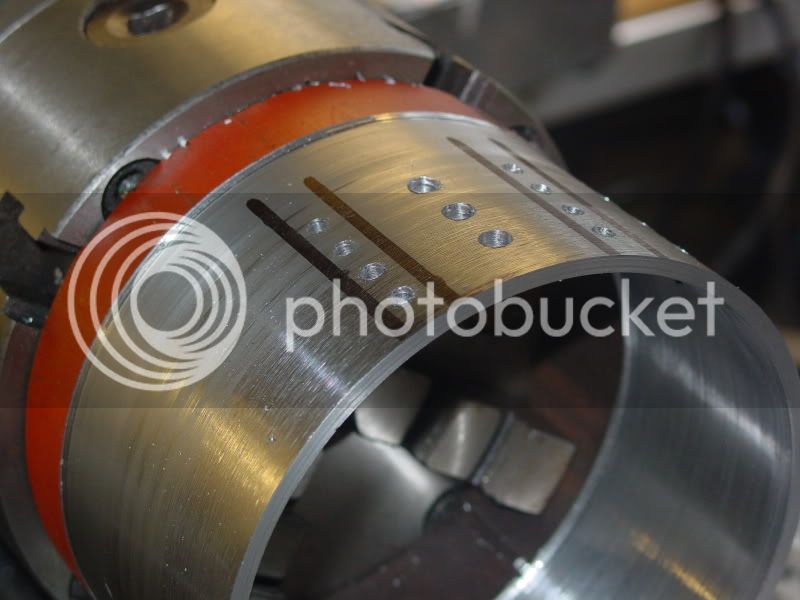

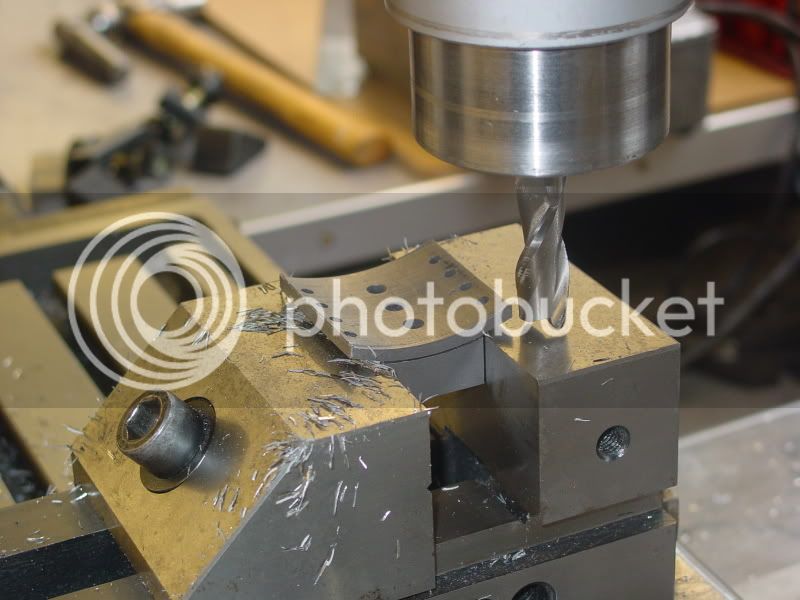

I think I will silver solder the steel block to the saddle and then try screwing that to the cylinder. It should be stong enough. The valve chest and cover will be fitted with studs. There is still quite a bit of work needed to the cylinder that will be easier without the saddle in the way.

Cheers

Rich

I think I will silver solder the steel block to the saddle and then try screwing that to the cylinder. It should be stong enough. The valve chest and cover will be fitted with studs. There is still quite a bit of work needed to the cylinder that will be easier without the saddle in the way.

Cheers

Rich