Almost going real time now, Im getting caught up.

I filled the fuel tank with Coleman fuel, its been about three days now and holding perfectly, no leaks.

I sealed the cooling tank and tested it overnite, it had small leak which seemed to be from the bottom of the soldered seam. Not unusual, Ive had that happen before. I put a coat of fuel tank sealer on the inside of the entire tank and its now holding water.

That first water test complete it was the time to test the rest of the piping and the cylinder to liner.

For this the cylinder head was removed so I could see that joint. With the cooling tank attached and filled, about an hour later no leaks. Good show.

While it had water in it I figured I might try a preliminary test, to see if the water would thermosyphon when the cylinder was heated.

For this I used a heat gun set on low and propped it up to blow directly into the cylinder.

I also dropped a thermometer into the tank to give me an idea of the rate of flow.

The gauge is bottomed out which is about right. This time of year the our well water is really cold about 45 deg.

With the heat gun running about ten minutes, there was absolutely no flow although the cylinder was almost too hot to touch.

I noticed an air bubble in the end of the inlet pipe, telling me it might be air bound so I tipped the engine and tank back a bit and a string of bubbles came out, followed by some fairly warm water.

That made me smile a bit.

If one thermometer was good, three would be even better.

About an hour into the test, this was the result.

The glass thermometer was right below the inlet reading almost ninety.

The probe on the little one was about halfway down and the probe on the big one almost at the bottom.

Water was flowing and the cylinder was cool enough touch, even though the heat gun was heating more than just the inside of the cylinder.

And about another hour things were a bit warmer but not alarmingly.

Im thinking that I should to be able to run the engine some time and not overheat it. Ill find that out for sure when it is running.

I ran the test for another twenty minutes or so with not much increase in temps, and decided there was nothing further to prove. Im happy.

After another hour, all the thermometers were at right about eighty.

Next two pics show the temp at the nozzle of the heat gun and then the side of the cylinder just before I shut things down.

And yeah, I have a thing for thermometers.

While I had the two piece cylinder head off I decided to casterize it.

Casterize: (not a real word, I think) make machined parts look a little bit like castings. Simply put, this is brutalizing the part with a coarse wire wheel on the bench grinder.

I also upgraded the spark plug from the ¼-32 plug I had in there to a 1/16NPT, two piece plug I made about six months ago.

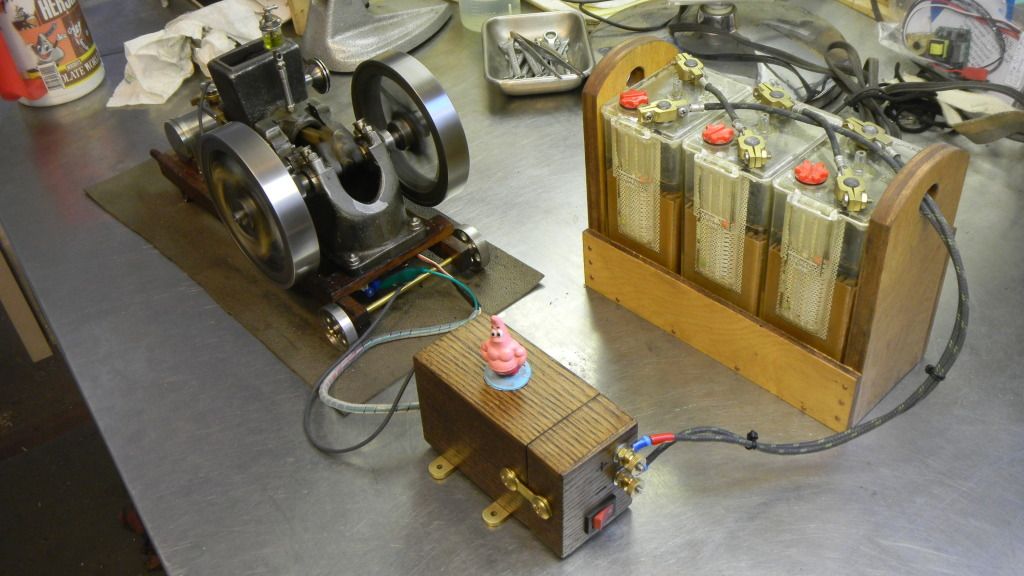

Now, with the cylinder head off and the side shaft cleared of cams, I can slide the magnet wheel on and get along with figuring out the placement of the hall sensor.

GUS

PS, Is it just me, or has the new version of Photobucket added a new layer of difficulty to adding pictures to our posts?